X Email Mobile

Sorry! This Product is not Available Now.

You May Like

fairy toy stick bounce ball magic wand flash ball promotional gifts children's luminous toys night market stall drainage

¥ 1.44/ piece

Evergreen International co ltd

factory creative candy dinosaur doll doll unicorn plush toy sleeping pillow birthday gift cross-border batch

¥ 8.5/ piece

Baoding Mengmeng Rabbit Trading toys

prize claw big eight-inch traffic model plush toy doll down cotton baby wedding tossing activity batch gift

¥ 4.5/ piece

Yiwushi Hongmai Household goods Limited

led cylinder bulb e27 super bright energy saving constant current flicker-free indoor lighting

¥ 1.78/ piece

LEDNE LED LIGHTING EXPERTS

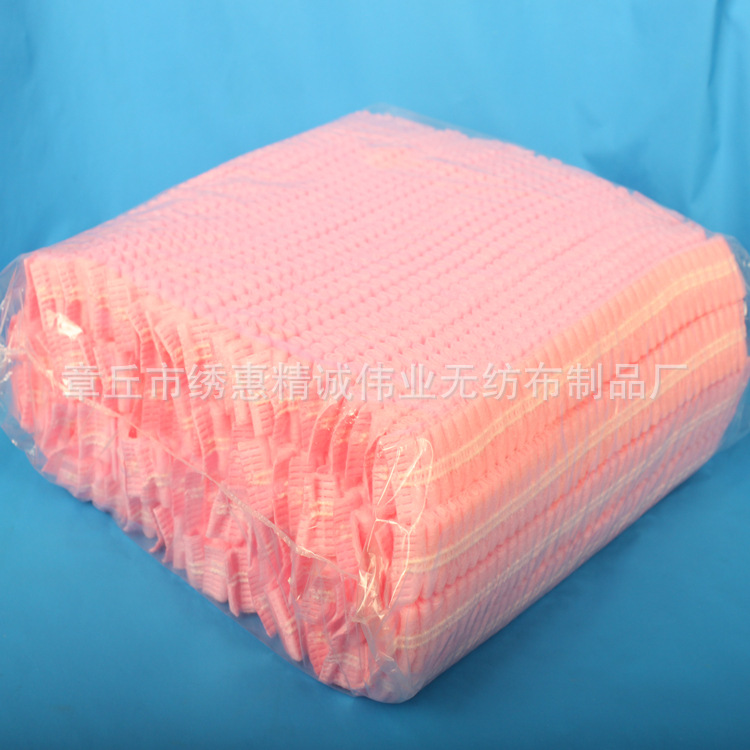

Disposable Non-Woven Fabric Mesh Cap Double Rib Mesh Cap Household Dust Covers Chef Cap Disposable Bar Cap Labor Protection

¥ 0.04/ pcs

Zhangqiu City embroidery Hui Jingcheng Weiye non-woven products factory

ins sexy hot girl off-shoulder autumn and winter bottoming women's top korean-style slim bottoming cool top women's wholesale

¥ 16.13/ piece

hao xing

plush toy coin purse embroidery cartoon cute wallet children wallet boutique cartoon animal wallet pouch

¥ 1.65/ piece

Yuer.toys

european and american style geometric flower spot drill hollow stars spot drill hollow pentagram exaggerated simple stud earrings

¥ 3.8/ pair

DUO DUO Stainless Steel

2055 xiaohongshu reading glasses men and women old square frame anti-blue light ultra-light middle aged instafamous glasses

¥ 5.83/ pair

hao xing

super bright high power led solar outdoor courtyard human body induction waterproof integrated solar street lamp

¥ 396/ piece

YIWU HAIMAO LIGHTING.CO.LTD

Radar Infrared Sensor Lamp Voice Control Sound and Light Control Bulb Corridor Garage Corridor Intelligent LED Infrared Globe

¥ 1.05/ pcs

MCLED Lighting

Model Car Remote Control Car Children's Simulation Car Car Toy Four-Way Burst Crack Boy F081671

¥ 15.5/ pcs

Big hippo Toys

applicable to iphone16 phone case acrylic magnetic apple 15 macaron silicone drop-resistant transparent protective case 14

¥ 3.6/ piece

keke

swim ring capybara doll doll plush toys girl's birthday gift doll pillow female

¥ 23.5/ piece

AI Fei plush toy factory

q version superman monster series toy blind box cartoon anime digasello small hand office prize claw doll

¥ 2.63/ piece

lufamaoyi

Super Clean Keyboard Dust Cleaner Gel For Car Keyboard Mobile Cleaning

¥ 0.8/ pcs

AVATAR GLUE FACTORY

60 cartoon doll micro particle building blocks gifts for boys and girls compatible with lego stall educational assembled toys wholesale

¥ 1.3/ box

Happy Trading Firm

Magnetic Phone Case Mobile Phone Shell for iPhone Phone Case Transparent Case Mobile Phone Phone Case Samsung Magnetic Phone Case

¥ 5.6/ pcs

Guangdong Honfhuo Hardware Elctronic

2025 new spring festival full adhesive advertising couplet plus printed logo sun-resistant tearproof new year goods tear-resistant new year couplet

¥ 5.41/ pay

xiaotudou

925 silver needle pearl earrings for women bow stud earrings earrings wholesale

¥ 2/ pair

Earrings Bracelet Necklace Jewelry Store

Cross - border hot style breathing light landscape light LED colorful waterproof decoration simple sen

¥ 16/ pcs

义乌市邦信灯饰有限公司

cross-border sold jewelry european and american new stainless steel titanium steel simple bracelet amazon creative hip-hop fashion bracelet for women

¥ 2.8/ strip

DUO DUO Stainless Steel

ufo intelligent induction uav small aircraft aircraft suspension four-axis ufo colorful light children's toys

¥ 36/ piece

siya

cross-border christmas headband antler hairband halloween party farcent headdress stall night market luminous toys

¥ 0.72/ piece

keke

foreign trade women's clothing summer new short-sleeved t-shirt women's round neck printed bottoming shirt one-piece delivery

¥ 19/ piece

Xian Jie Commodities Firm

2025 new year gift national style snake plush toy doll toy doll snake year doll

¥ 8.2/ piece

Open fire plush toys

Fishtail Opal Bracelet String Beads Bracelet Hand Jewelry Wholesale

¥ 8/ piece

Earrings Bracelet Necklace Jewelry Store

casual shoes men's lace-up sports autumn and winter low-top non-slip rubber bottom wedge two-color korean casual sneaker

¥ 31.25/ pair

hao xing

rejoice shampoo liushen shower gel colgate toothpaste grace towel toothbrush

¥ 30/ set

Yiwu Yongchen Daily Chemical Co., Ltd.

red festival flocking lantern outdoor waterproof new year spring festival iron mouth lantern festive long brush holder lantern wholesale

¥ 2.97/ piece

Yiwu Xiqing Daily Necessities Factory

heart-shaped glasses factory candy jelly color love glasses personality european and american sunglasses men and women peach heart sunglasses

¥ 0.88/ pair

Haoge TradingTOP