Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

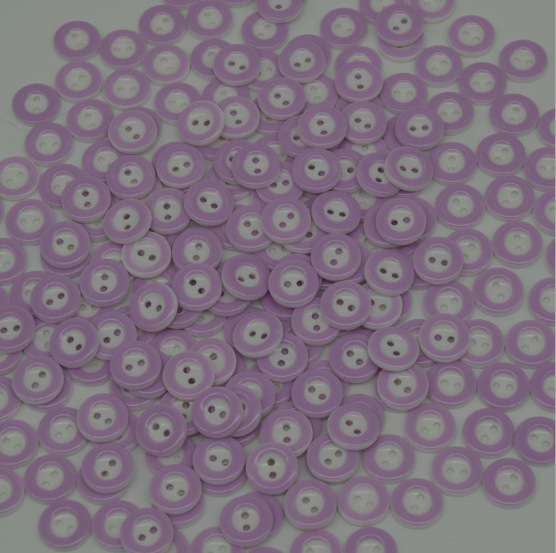

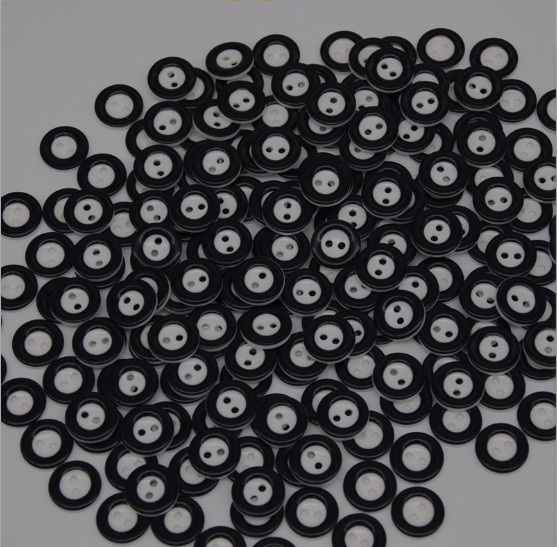

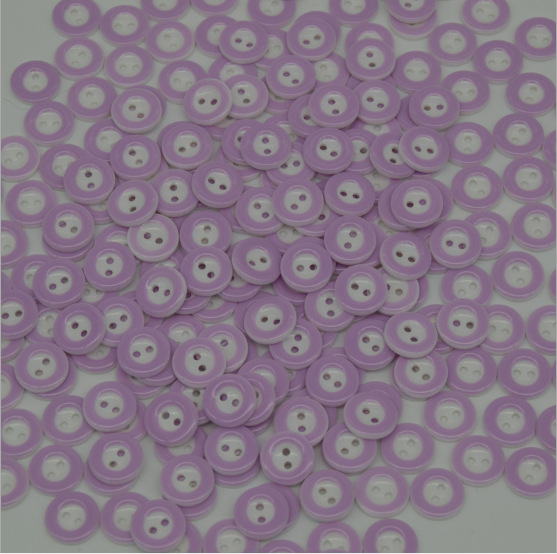

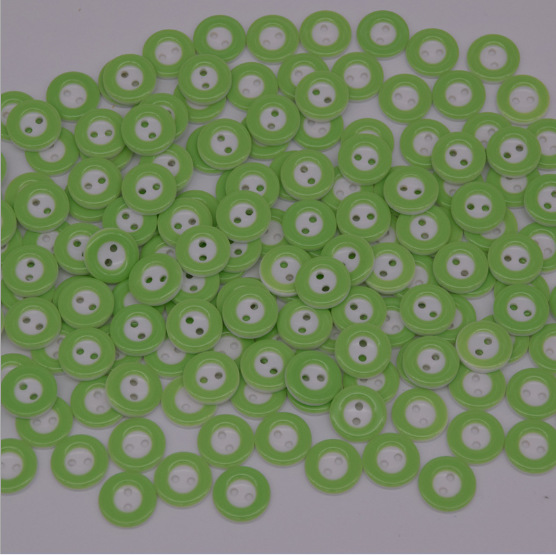

| color: 16l = 10.0mm | ¥0.02 | 999999 granule available |

|

| color: 18l = 11.5mm | ¥0.02 | 999999 granule available |

|

| color: 20l = 12.5mm | ¥0.03 | 999999 granule available |

|

| color: 24l = 15.0mm | ¥0.04 | 999999 granule available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Important tips for selecting buttons: Buttons have different adaptability in different environments, so when selecting buttons, it is necessary to specifically ask the manufacturer: 1. Which products will the buttons be used on (such as trench coats, shirts, fashion women's wear, suits, washable denim or acidic leather products) or any special requirements. 2. The requirements for the components of the buttons, whether they need to be lead-free and nickel-free, or can pass the needle detector. 3. The 16L, 18L, and 20L refer to the model of the buttons, which is measured by the diameter of the button. Simply put: the diameter divided by 0.635 is the model. Moreover, all model numbers are even numbers without odd numbers. Usually, the buttons for shirts are 16L, 18L, and 20L, which are more common. In addition, buttons for fashion women's wear are all special buttons, very fashionable and novel, and need to be specially made. The majority of brand clothes will make LOGO on their clothes buttons, usually with different shapes and letters, and all have brand LOGO engraved on them, which is a very detailed thing. If it is well done, it will become a symbol.

Method of Button Quality Inspection

1. Compare the sample. Check if the color and model match the sample.

2. The surface should not have cracks, gaps, unevenness, or obvious scratches;

3. The surface and back are free of cracks and bubbles; there is no rotten edge or uneven thickness.

4. The patterns should not have obvious deformation, no white eyes, white circles, or other phenomena.

5. The eyelet should be smooth and unobstructed; the needle holes should not be punctured or broken, and they should be symmetrical and free of large holes. If it is an invisible eyelet, the invisible eye slot should be smooth and free of obvious cracks.

6. Buttons of the same batch should have color differences no lower than Grade 4 of GB250, and compared with the sample, they should not be lower than Grade 3 of GB250.

7. Packing inspection: After the appearance inspection is fully qualified, the product is then packed. During packing, a quality certificate or other labels should be included. The quantity of the packaging should match the prescribed amount, and the actual number of each bag should be consistent with the prescribed amount. If the thickness or other reasons cause the quantity to exceed the tolerance, then the entire quantity must be inspected.

After going through several strict inspection procedures, only those buttons that pass the inspection can then be sold in the market.

Update time:

TOP