Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| Number | Unit-price | Total | |||

| I want to buy: | × | 0.6 | = | 0 |

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Yiwu Huali plastic bag factory 9yr.

Contacts:Chen LilyChat

Mobile:86-15868940207

E-mail:582752033@qq.com

Packaging information

CTN Size: 50 × 20 × 80 cm

G.W./CTN:40 kg

QTY/CTN:8000 piece/carton

*************************************************************************************************************************************************************************************************************************************************************************************************************************************************************************

![]()

![]()

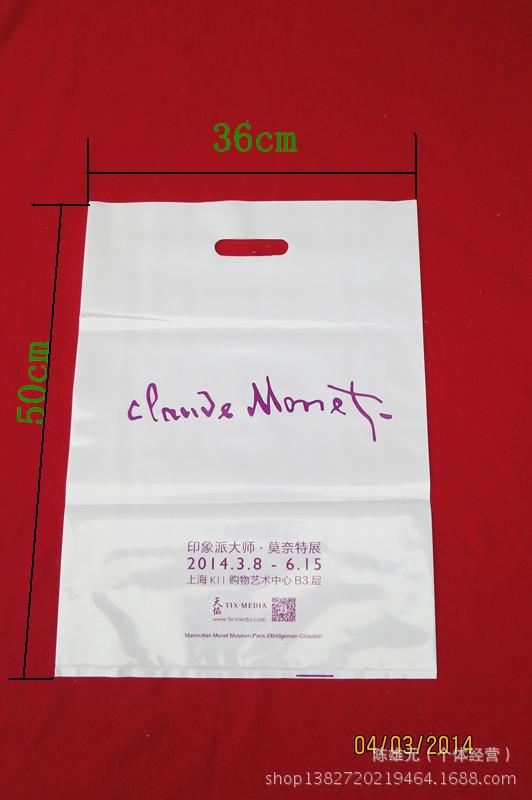

Material: LDPE

Specification: 36cm*50cm

Thickness: Double-sided 16 threads (actual thickness is 15.8-16 threads)

Quantity: 50 pieces/pack

Workmanship: Flat Knife

Common Problems of Plastic Bags:

1. Material color difference and thickness: PE is commonly divided into high-pressure polyethylene (LDPE) and low-pressure polyethylene (HDPE). LDPE feels softer with a shiny surface, while HDPE feels harder with a matte surface. If the customer has a sample, there may be a slight color difference due to the different proportions of color masterbatch added in each batch, so in the color matching process, it is only possible to achieve a close approximation and not a perfect match.

PE is made by melting plastic particles into a liquid at high temperature, cooling them into a solid state by a fan, and then pressing them into a sheet. Due to the precision of the machine, a ±0.005mm/layer deviation is considered reasonable.

2. Regarding printing: CMYK is a four-color printing method mainly used in offset machines, while the special color printing for plastic bags is mainly manual color adjustment for gravure printing. Therefore, your manuscript cannot be used as a reference. Please provide the Pantone color number or the actual item.

Special color printing may have a certain color deviation. Customers who are particularly sensitive to color differences are requested to note this in advance and communicate clearly before production. If it is a full-color printing, there may be local white spots. If it is not a large area, it is within the reasonable range.

3. About the workmanship: due to the plastic's softer characteristics, subsequent processing techniques such as folding edges, punching holes, and slicing may result in some position deviations.

4. Regarding Quantities: Due to the losses in the processes of blow molding, printing, and bag making, the actual product quantity may deviate from the contract quantity by ±10%. The settlement will be based on the actual quantity delivered.

Purpose: Can be used in factories and shopping malls, including shopping bags, roll bags, flat bags, handbags, shoulder bags, and more.

The invention of plastic bags has brought great convenience to human life, but an increasing number of people do not know how to use them effectively, leading to the globalization of plastic bag pollution. Compared with traditional plastic bags, eco-friendly bags have the following advantages:

1. The dissolution rate can be designed and selected, completely dissolved in water, non-toxic and non-polluting.

2. High tensile strength and good tension.

3、High transparency and good luster;

4、High softness, good touch sensation.

5. Good oil and solvent resistance, heat sealable, printable.

6. Low air permeability coefficient, good air resistance.

7. Can be added with plastic buckle or self-adhesive bags.

8. Excellent anti-static performance, does not attract dust, etc.

9. Can be degraded by water, air, sunlight, and bacteria. It usually takes about a month to decompose into harmless substances.

Update time:

TOP