Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| 10ml | ¥0.0 | 5000 piece available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Segasan Adhesive Products Co.,Ltd 13yr.

Contacts:ELENAChat

Mobile:86-15958482343

E-mail:zengmei0519@aliyun.com

Specification:10ml

313 will cure under ultraviolet light and slowly cure in sunlight. A light source with a wavelength of 220~260nm is beneficial for surface curing. The curing rate, the final depth of curing, and the surface dryness are related to the ultraviolet light source, the illumination time, and the material's transmittance. It is recommended that the final curing process be determined by experiments.

Positioning Time:

6S- 125W Philips high-pressure fluorescent lamp, 4.5 MW/CM2 UVA, 3mm thick PMMA/PMMA

Typical post-curing performance:

Tensile shear strength (GB 7124-46) overlap area 25×5 = 125mm²: PS/PS, 4~5MPa is the PS failure at 30°C

Instructions:

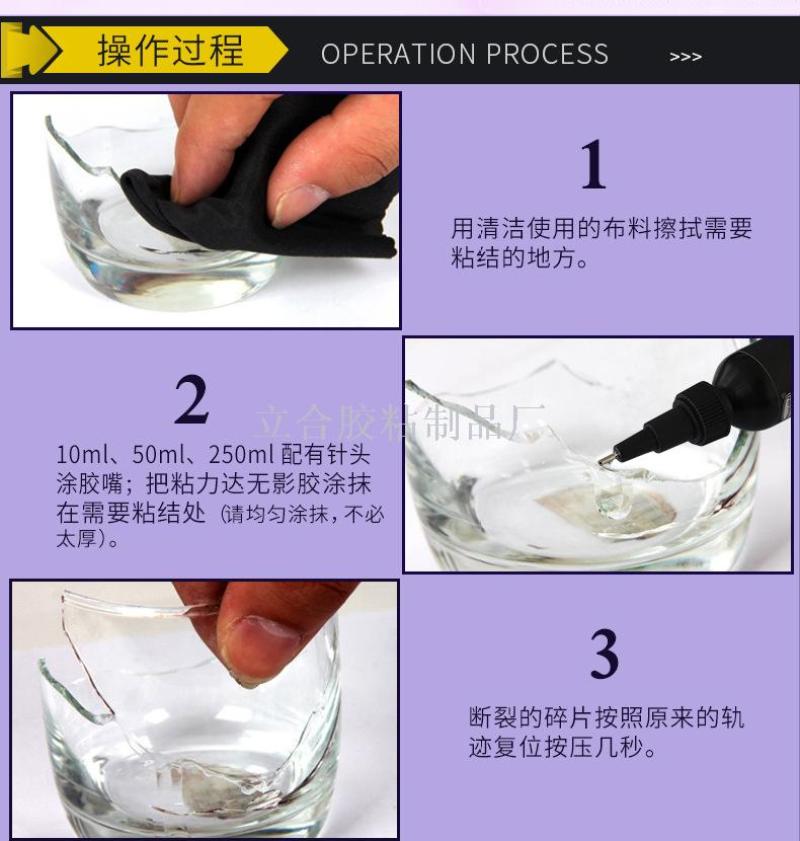

1. Clean and sizing, the surface of the adhesive must be dusted, degreased, and dried before bonding. Determine the amount of adhesive water as needed.

2. Temperature-sensitive materials, such as thermoplastic plastics, require cooling devices.

3. Inspect the curing of plastic materials to prevent stress cracking due to liquid.

4. Excess glue can be wiped off.

5. Do not pour the remaining glue back into the original packaging to avoid contamination.

6. When the temperature is below 20 degrees, preheat the substrate to 30 to 35 degrees to ensure adhesion.

Notes:

Avoid contact with eyes, skin, and clothing. The product may cause mild irritation to eyes and skin. If you accidentally get it in your eyes, immediately flush with large amounts of water. If you still feel uncomfortable, seek medical attention. Wash skin immediately with soap and water. Wash clothing before wearing. Keep out of reach of children.

Steps:

One or two adhesive surfaces need to be cleaned and must be flat.

When the second, when distributed on one side or aluminum cake, when reassembly must be pressed, the smaller the gap, the higher the strength after curing, and no bubbles should be produced; positioning must be accurate, there is only one chance, if it is too fast, it will be very troublesome and easy. Persevere.

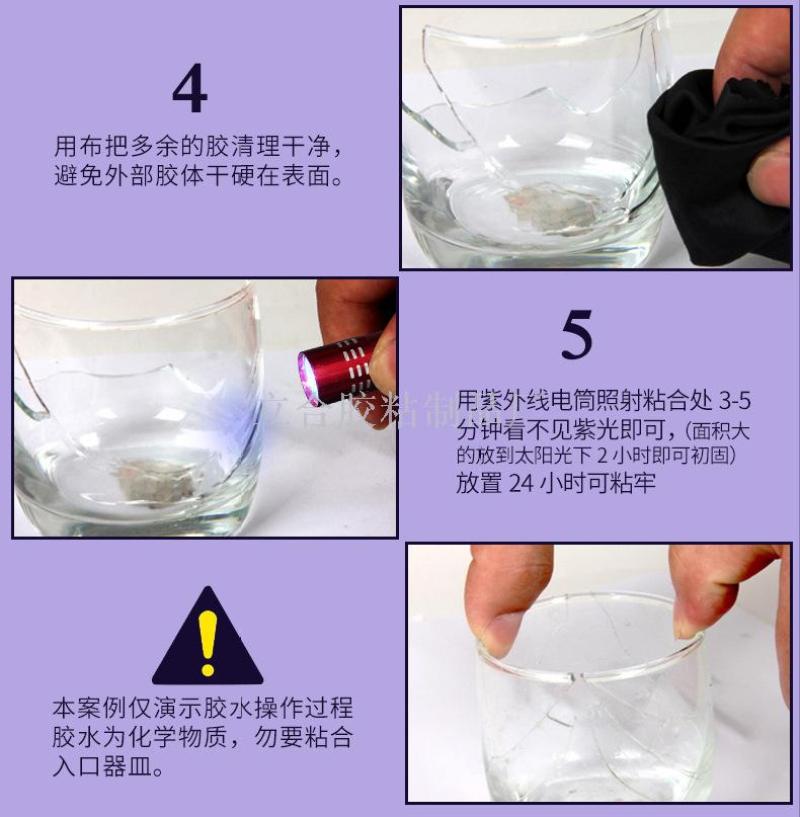

Third, clean up any excess glue.

Fourth, UV curing, or curing under direct sunlight.

Dear! Glue can cure in the sun, but it's best to expose it to the sun for about 1-2 hours.

If you have a UV lamp, it's best to turn it on for 3-5 minutes, and that should be enough.

Viscous phase: As long as one side of the product is transparent, it can be used. This is a type of light-curing adhesive, which is known as a shadowless glue. UV glue is called shadowless glue because it does not leave a glue residue and cannot be seen, so it is called shadowless glue.

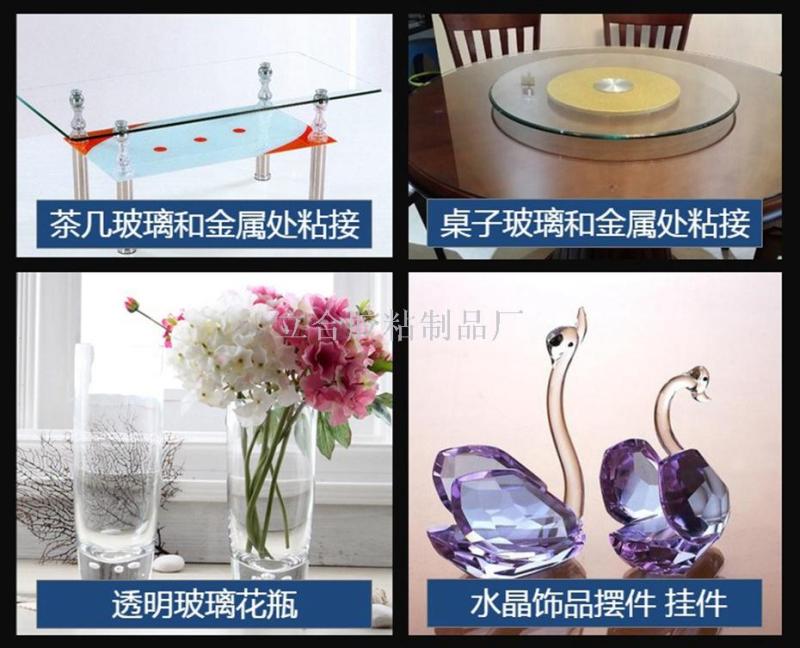

Adhesive products: Glass, ABS, PVC, Plastic, Crafts, Gems, Gifts, Packaging, Crystal, Plastic, PVC, Organic Glass, Coffee Tables, Diamonds, Electronics, Photos, etc.

Update time:

TOP