Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Price Negotiable

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

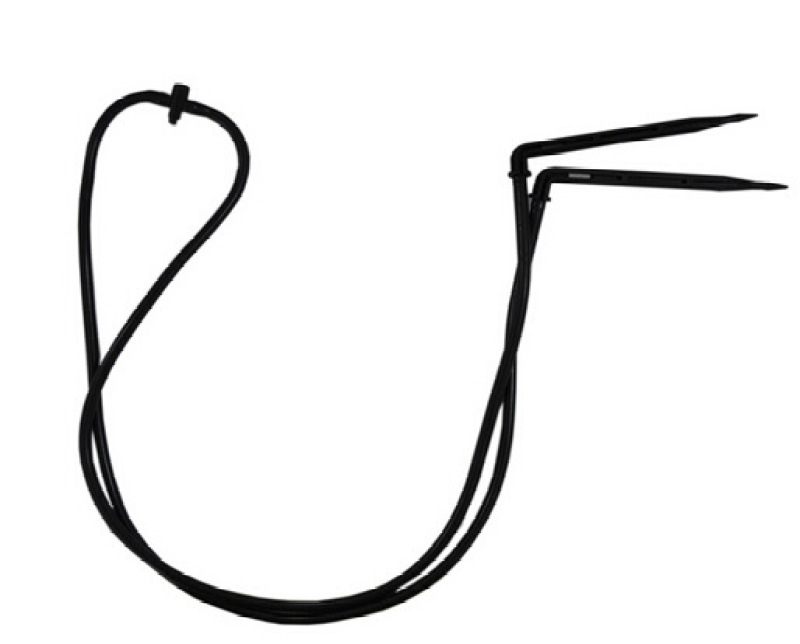

Four-outlet drip arrow, one-outlet four/one-outlet two drip arrow kit, automatic drip irrigation for flower pots and flower troughs, drip irrigation tools

Product Information:

1Control temperature and humidity—Reducing water evaporation and lowering indoor humidity have a significant effect. Using sub-mulch drip irrigation, which means placing the drip irrigation pipe (or tape) under the mulch, results in even better performance. Additionally, drip irrigation is convenient to operate, allowing for high-frequency irrigation. Due to the small size of the flow orifices and the slow flow rate, each irrigation session lasts longer, resulting in a smaller range of soil moisture changes. Therefore, it is possible to control the soil in the root zone to maintain a humidity suitable for the growth of vegetables, flowers, and other plants for a long time. By controlling the indoor air humidity and soil moisture, the occurrence of pests and diseases can be significantly reduced, thereby reducing the amount of pesticides used.

2Guan Shui Jun YunDrip irrigation systems can effectively control the flow rate of each emitter, resulting in high uniformity of irrigation, usually reaching80percent sign—90percent.

3Saves laborDrip irrigation is water supply through a network. It is convenient to operate and easy to control automatically, thus significantly saving labor. At the same time, when using drip irrigation, only a local area is watered, leaving most of the surface dry, which reduces the growth of weeds, thereby reducing the labor needed for weeding.

4The temperature drop is very small.The operation mode of drip irrigation is to adopt a shallow and frequent dripping method, with very small amounts of irrigation water each time, which almost does not cause a decrease in low temperature.

5Drip irrigation can be combined with fertilization.—Timely and appropriate application of water and nutrients directly to the roots of crops improves the utilization rate of water and fertilizer.

6Can reduce the occurrence of pests and diseases

7Maintain soil structure

Under the influence of traditional furrow irrigation with a larger irrigation amount, the facility soil is subject to more erosion, compaction, and erosion. If tillage is not timely, it will lead to serious compaction, decreased aeration, and a certain degree of destruction of soil structure. However, drip irrigation is a micro-irrigation method, with water slowly and evenly penetrating into the soil, which can maintain the soil structure and form an appropriate soil water, fertilizer, and heat environment.

8Improving Quality, Increasing Yield and Efficiency

Due to the application of drip irrigation, the amount of water and fertilizer, and the occurrence of pests and diseases are reduced, which can significantly improve the quality of the product. In short, compared to traditional irrigation methods, after the use of drip irrigation in greenhouses or greenhouse horticulture, it can greatly improve the yield of products, advance the time of market, and reduce the amount of water, fertilizer, and labor costs, etc., so the economic and social benefits are significant. The drip irrigation technology of horticultural facilities has adapted to the requirements of high-yield, high-efficiency, and high-quality modern agriculture, which is also the reason why it can exist and be widely promoted!

9andApplicable scope wide

Economic crops such as fruit trees, vegetables, flowers, nurseries, grapes, peaches, pears, apples, chestnuts, oranges, tomatoes, cucumbers, cotton, corn, pasture grass, etc.

Product images and installation/usage images:

Product Name:A straight shotset

Product details:Two drops of arrows

Each 3X5MM tube is 50CM long

One three-way fitting

Product performance:The drop arrow has a total radius of about 12.5CM. The insertion needle is 12CM. The flow rate of a single drop arrow is 2-3 liters per hour.

Can be equipped with pressure compensation dropper (4L/H 8L/H) to increase the stability of flow.Can be directly installed on the PE pipe.

滴箭微灌The main features of this irrigation equipment are to a great extent reduce labor intensity, realize irrigation and fertilization integration automation, and save the largest amount of labor.95%Watering is uniform, with uniformity reaching85—95%Saves water, more water-saving than manual watering.50—70%High water and fertilizer utilization rate, reducing pollution to the environment, low water evaporation, reducing air humidity, reducing pests and diseases. Suitable for those with small irrigation amount per time, but with frequent irrigation frequency throughout the production cycle, even reaching daily irrigation times.3—5The potted flowers.

Dripper irrigation equipment requires a substantial one-time investment, and under the same scale, it is more expensive than spray irrigation equipment.5—7The investment in micro-spraying equipment is relatively high.3—5Times, mainly invested in the water supply branch pipe,PEWater supply main滴箭andPVChoseHowever, in the process of pot-grown flower production, spray irrigation and micro-spray systems are less often used. The main reason is that when the flowers are quite lush, it is difficult to irrigate the substrate with water from the spray, leading to the phenomenon of not being able to irrigate thoroughly, which is both a waste of water and fertilizer and cannot provide the necessary water for the growth of the flowers. Frequent watering of flowers will reduce the display time, thereby affecting the value of the flowers.。

Selection of Flowering Plants for Drip Irrigation Equipment

滴箭微灌When the equipment is applied in the production of potted flowers, it is necessary to carefully inspect and install the drip arrows at the beginning of each flower production cycle. Each drip arrow should be inserted into the corresponding position of the pot substrate. The position of the drip arrow is generally relatively fixed in the flower production cycle, and after each production cycle, each drip arrow must be carefully removed from the substrate of the pot, cleaned, and prepared for the next use. Although these tasks are simple and easy, they require a large amount of work and are relatively tedious. They are the most time-consuming and labor-intensive part of the daily application and maintenance process of the drip arrow equipment. Moreover, the frequent installation and disassembly of human activities may cause damage to the equipment. According to our preliminary statistics, after each flower production cycle, there will be1—2%The drip arrows must be repaired or maintained, or replaced, to serve the next production cycle; therefore, in using the drip arrow micro-irrigation equipment, we believe it is more suitable to choose those flower species with longer growth cycles. Reducing the number of times for installation and disassembly and cleaning of the drip arrows can extend the service life of the equipment and reduce the depreciation costs of the equipment.

The requirements for the planting substrate for drip irrigation equipment

Potted flowers generally require a substrate that is well-drained, breathable, and cost-effective. For example, adding general peat soil.1—3%Perlite or plastic foam; these substrates have strong hydrophobic properties. When watering artificially, it is generally recommended to use a special flower spray head or manually shake the substrate, ensuring that the water is evenly distributed over the entire surface of the pot. Under the force of gravity, the water will seep down into the substrate, ensuring that the entire pot is thoroughly moistened. However, for general substrates, it is recommended to use a spray head or manually shake the substrate to ensure that the water is evenly distributed over the entire surface of the pot.滴箭Micro-irrigation equipment does not achieve the desired irrigation results, and a single dripper can only irrigate a diameter of5CMSoak the substrate within the range.20—30After continuous drip irrigation for a second, there is usually water leakage at the bottom of the pot; while the diameter of the pot is usually larger than that of the plant.15CMIn this way, there will be 80%The substrate cannot be watered, and the roots of the flowers are evenly distributed in each part of the pot substrate, and the majority of the roots have no water to absorb, causing the flowers to lack water, even drying up.

To solve the uneven watering of drip irrigation nozzles in pot substrate, besides improving the structure of the drip nozzle, it is more important to develop a new type of mixed substrate. The movement of water molecules in this new substrate is similar to that in cotton fiber, allowing for more uniform distribution of water.20In a matter of seconds (or even shorter), water molecules in the potting soil permeate in any direction, resulting in an even rate of moisture content within the same potting soil.90—95%Ensure that the water drops out of the drip device.85—90%Adhered to the substrate.

Based on the research of the water-absorbing ability of various substrates and fillers, through multiple comparative practices with different components, we have developed a mixed substrate that meets the current requirements of drip arrow micro-irrigation equipment. Its main components are peat soil, with a clay content of3—5%The content of hard objects such as branches is in1-—2%and through8—15Sieve screening; add3—5%White feather-like material, white feather-like material is a special plastic fiber product, which contracts after coming into contact with water into water-containing higher clumps, improving the structure of the substrate. The addition of white feather-like material can improve the water absorption and retention ability of the substrate.20—30%In addition, coarse fiber materials such as coco coir are also added, with their length generally being around5CMThe addition amount accounts for the total weight of the substrate.10—15%After comparing the tests, the uniformity of moisture content in the substrate with coconut coir is higher than that without coconut coir, and the lateral moisture penetration is faster. The drip arrow micro-irrigation equipment has a satisfactory performance in similar substrates.

The selection of filtration pressure equipment and water supply pipelines

For each flower production department, it is hoped to choose a universal drip irrigation equipment that can adapt to various flower production needs to meet the needs of rotation and variety production. Moreover, from the current production situation, the purpose of using drip irrigation equipment is very clear. First, it solves the problem of labor intensity in flower production processes, and second, it solves the problem of uniformity in flower production processes. Therefore, many flower production units choose these devices with the aim of simple operation, reliable operation, and economic durability. The drip irrigation system for filtering and pressurizing equipment has no great difference in form for each production unit, mainly due to the difference in irrigation scale and the different capacity of water and fertilizer solution processing per unit time. The process flow is as follows:

Water source——Pressure Pump——sandstone filtration器——Centrifugal screen filter——Pressure Pump——Desalination treatment——Fertilizer Injection Equipment——Solution Monitoring Equipment——滴灌"管"在中文中通常指的是一种用于控制或引导流体、气体、粉末等物质的设备或工具。例如,水管、气管、烟管、风管等。在中文里,"管"也可以指负责管理或监督某项事务的人,例如"管理员"、"主管"等。——Watering can.

If the water source quality is good, users can avoid the sand and stone filtration equipment and retain the centrifugal mesh filtration equipment. The performance of the centrifugal mesh filter is relatively stable, reliable, and has a long life. It is usually selected.120above the eye levelnetFilterAs a filtration device for drip irrigation systems.

Dripper irrigation solution usually contains nitrogen, potassium, inorganic salts, and other soluble fertilizers, which have certain corrosiveness. Therefore, when selecting the water conveyance pipes, it is essential to choose pipes with corrosion resistance. Generally, pipes made of materials such as PVC, HDPE, and PP are used.PVCandPEThe diameter, flow rate, and length of a water supply pipe are related. It is usually calculated using the hydraulic formula of the pipe.

Selection of Drop Sprinkler Irrigation Devices

The structure is divided into two types, one of which is a small-hole direct-flow drip irrigation device with a simple structure, fast flow rate, and large flow volume, which can generally reach"15-20 L/HThe pressure change has a significant impact on the flow rate, and when the pressure is greater than0.12 MPaThere was a phenomenon of jetting, and the flow rate difference between the initial and terminal drops of the drip irrigation nozzle on a single irrigation pipe was greater than20%Early flower cultivation usually used with a steady flow device, but due to poor uniformity, it has gradually been phased out. Another method uses a sawtooth-shaped long flow channel structure for drip irrigation devices, which is quite complex. The sawtooth-shaped long flow channel structure has a pressure-reducing effect, resulting in slow flow rates and low flow volumes for the drip irrigation devices, which can generally reach1.5---2.0 L/HThe impact of pressure changes on flow is minimal, and there is no jetting phenomenon. The flow difference between the initial and terminal drops of the drip irrigation nozzles on a single irrigation main pipe is less than5%At present, this type of drip irrigation device is gradually being adopted in the production of pot-grown flowers.

The production of pot-grown flowers adopts the drip irrigation technology. In order to facilitate installation and disassembly, the drip irrigation devices are manufactured in blue or yellow, which is convenient for workers to identify in the pots. At the same time, it is connected with the following sentence.one out of four jointsOne-out-of-two jointsSteady Flow DropletCooperate to improve the performance of the drip irrigation system.

The application of drip irrigation technology in the production of potted flowers is an effective way to solve the shortage of labor force, and it is also a scientific technology that saves water, saves fertilizer, and manages the production in a large-scale manner. However, users must go through a process of trial and error, training operators, to master this technology, and only then can they achieve the expected results.

Update time:

TOP