Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| mixed batch | ¥0.0 | 99999999 piece available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

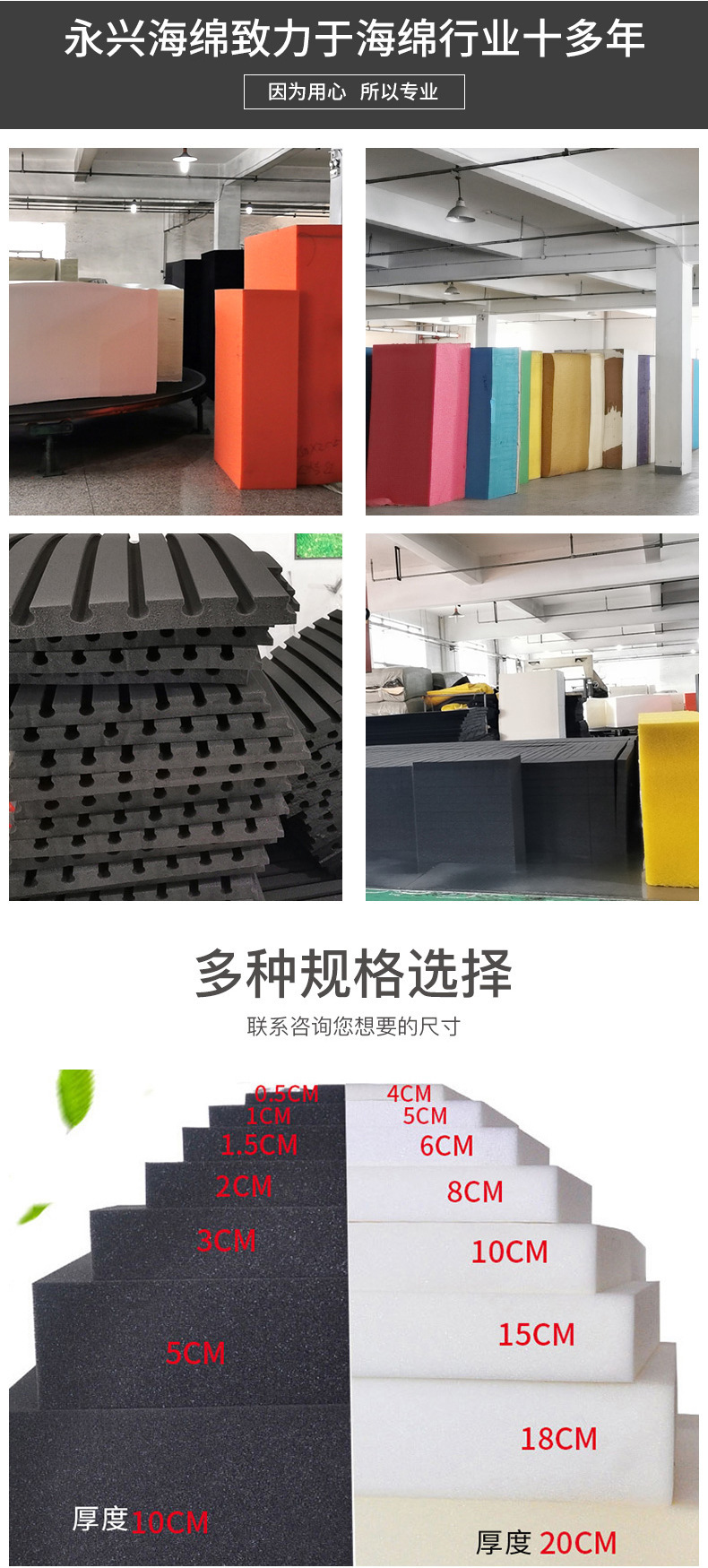

Our company produces various types of sponges, including:

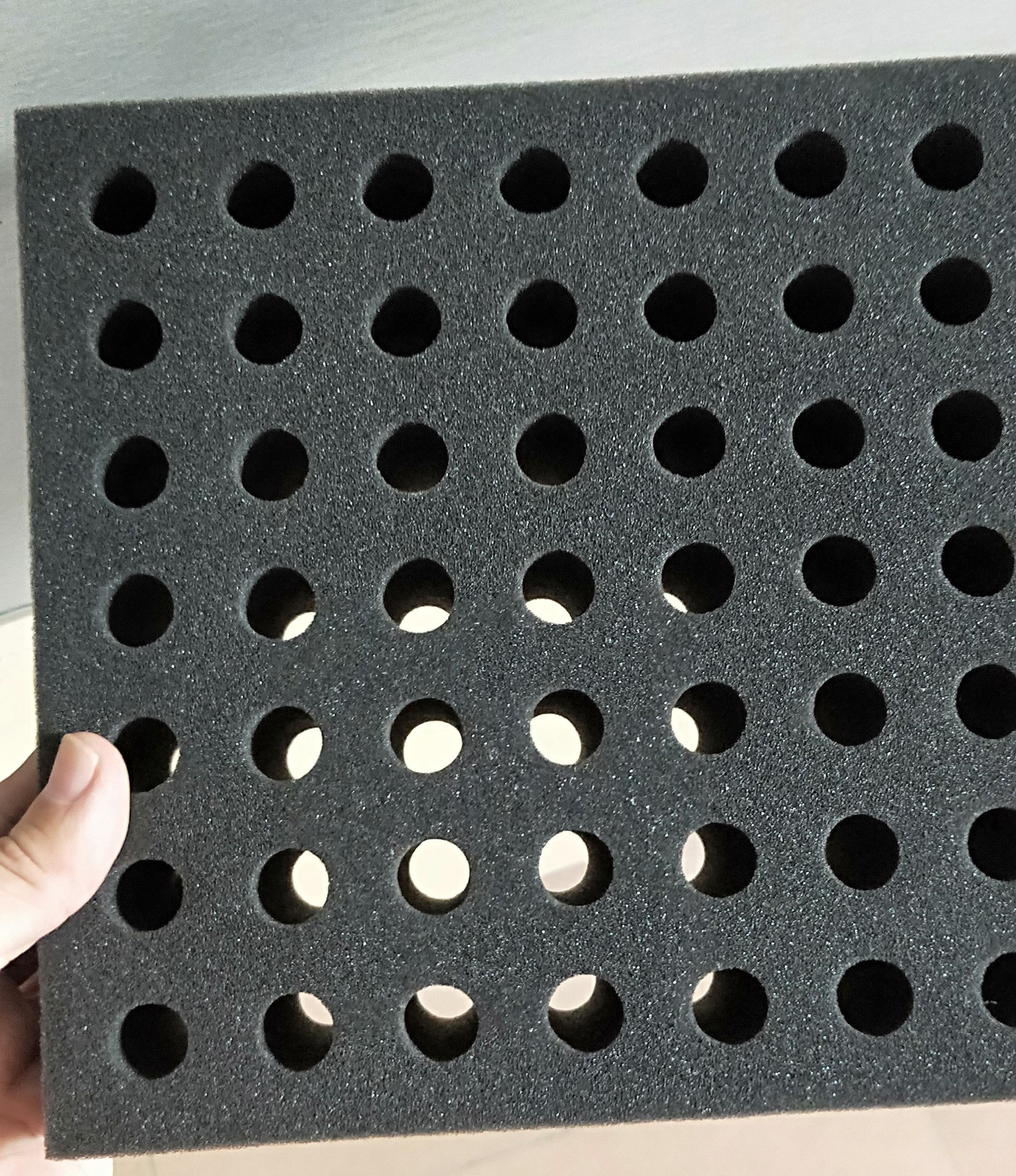

1. Punching and cutting sponge linings

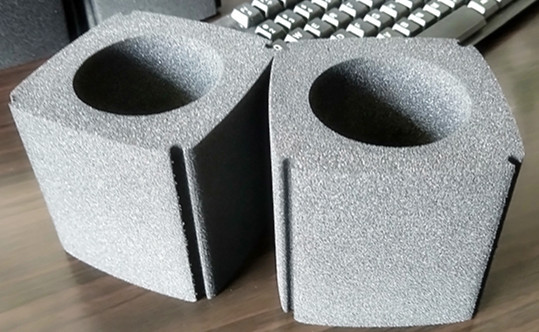

2. Curved one-piece molded sponge processing

3. Angled one-piece molded sponge processing

4. Sponge shape cutting

5. Sponge wire cutting

6. Semi-arc shaped processing

7. Trapezoidal wire cutting molding

8. Multiple material sponge composite processing molding.

In the field of sponge packaging inner support for various suitcase and bag products, we are specialized in AKG sponge packaging inner linings, glass and ceramic product sample design and processing sponge packaging inner linings, wine bottle packaging design, electronic product positioning packaging design sponge inner linings, and other industry sponge inner linings.

In terms of sponge material selection, our company offers a variety of sponge materials, including:

1. Polyurethane sponge

2. Polyether sponge

3. Flame-retardant slow rebound sponge

4. Non-halogen sponge

5. Fire-resistant sponge

6. Anti-static sponge

7. Electronic sponge

8. A variety of colors

9. Special sponges can be custom-made by hand.

The density of sponge ranges from 10g/mm3 to 130g/mm3, and we welcome your selection!

The sponge inner lining and sponge inner support also have standards for hardness, and hardness is one of its main indicators. Generally, only the higher hardness of the sponge inner support will have better wear resistance.

Update time:

TOP