Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

|

Material

|

Polyester Filament

|

|

Count

|

75D/2, 108D/2, 120D/2, 150D/2, 300D/2, 300D/3, 300D/1, etc

|

|

Packing

|

3g to 1.5kg/cone

|

|

Color

|

Over 400 different colors, also buyer's colors are acceptable.

|

|

Capacity

|

3000 tons/year

|

|

Certificate

|

ISO9001, Oeko-Tex

|

|

Description

|

Adopting highest quality of polyester filament as raw material, MH polyester embroidery thread is featured with shiny luster, high strength and excellent colorfastness. It is suitable for high speed embroidery and most kinds of textiles. |

100% Polyester embroidery thread is made of polyester FED yarn, dyed with disperse dyes on 125-135℃ degree, has excellent color fastness, good abrasion resistance, and excellent strength tenacity which keeping 50000 stitches unbreaking at 1000rpm high speed.

Normally it has counts as 120D/2, 150D/2, 300D/2, it is cetificated to Oeko Tex Standard 100 Annex 6.

For embroidery on clothing or accessories which are subject to wear-and -tear or frequent laundry, like caps, headwear, bags and accessories, team logo on sportswear, home textiles and children’s wear and sportswear, decorative seams on lingerie, children’s wear and sportswear.

MH embroidery thread advantages:

1) Exceptional Embroidery Performance6) Good hydrophilic properties, anti-static and anti-pilling

Color card

Packaging&Shipping

Our Factory

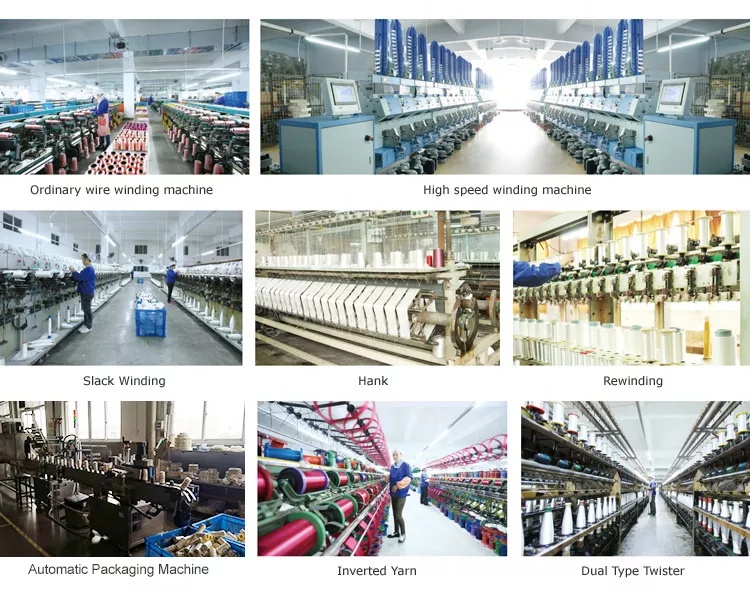

Now MH has three industry zones for thread factories, with 220,000m² plant area and 1100 workers.

MH Sewing Thread Factory producing process includes yarn spinning, dyeing, winding&packing, annual producing capacity is 30000+ ton.

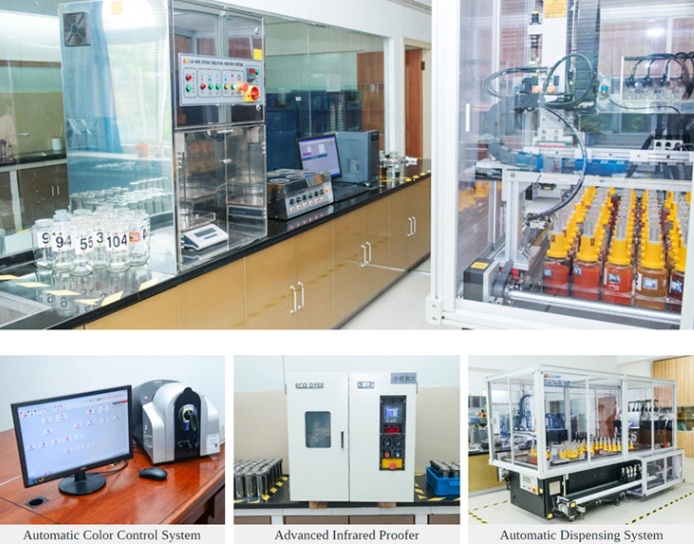

Color Sample Center

We recognize that providing accurate colors quickly is paramount to our customers' success and therefore have established an efficient and effective process to deliver with speed. The process starts with expert color teams and advanced color measurement equipment.

Test Center

Our test center has a complete set of test equipment, raw material would be tested before using on producing line, and finished sewing thread would be tested for its evenness, hairiness, strength, color fastness and sewing performance, only qualified thread could be shipped out to customers.

Dyeing

During the dyeing process, we not only care about color matching and color fastness, also we care about dyed yarn spindle shape which will effect thread rewinding quality. As the suitable yarn spindle shape will reduce the breakage rate during rewinding.

Green Manufacturing

MH has an advanced sewage treatment center and water recycling system is committed to acting in energy saving, environmental protection and green production.

Winding

The SSM TK2-20CT high-speed precision winding machines, not only ensure the thread cone in good shape with suitable tention, and has no deformation during transportation, but also has excellent performance in length and oil uniformity.

Automatic packaging machine

With this automatic packing machine, it keeps the sewing thread in nice and neat shape, and the sticker will be exactly in same place without slanting.

Other Embroidery Thread Machine

Certificate

MH has certificates of ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, Oeko Tex Standard 100 Annex 6 Class 1.

About MH

Ningbo MH was established in 1999, specialized in garment accessories and tailoring materials. After years of development, MH has set up business relationship with more than 150 countries, with sales amount $471 million. The main products are sewing thread, embroidery thread, ribbon & tape, embroidery lace, button, zipper, interlining, and other accessories & fabrics.

At present, MH owns nine factories located in 3 industry zones, with 382,000m2 plant area and 1900 workers.

Update time:

TOP