X Email Mobile

Price Negotiable

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Yiwu lumotianzhi paper products co. LTD 6yr.

Main Products:Specialty paper

Contacts:Xiao dong GaoChat

Mobile:86-18657965183

WeChat:13165129693

Address:Yiwu,Jinhua City,Zhejiang Province

Related items

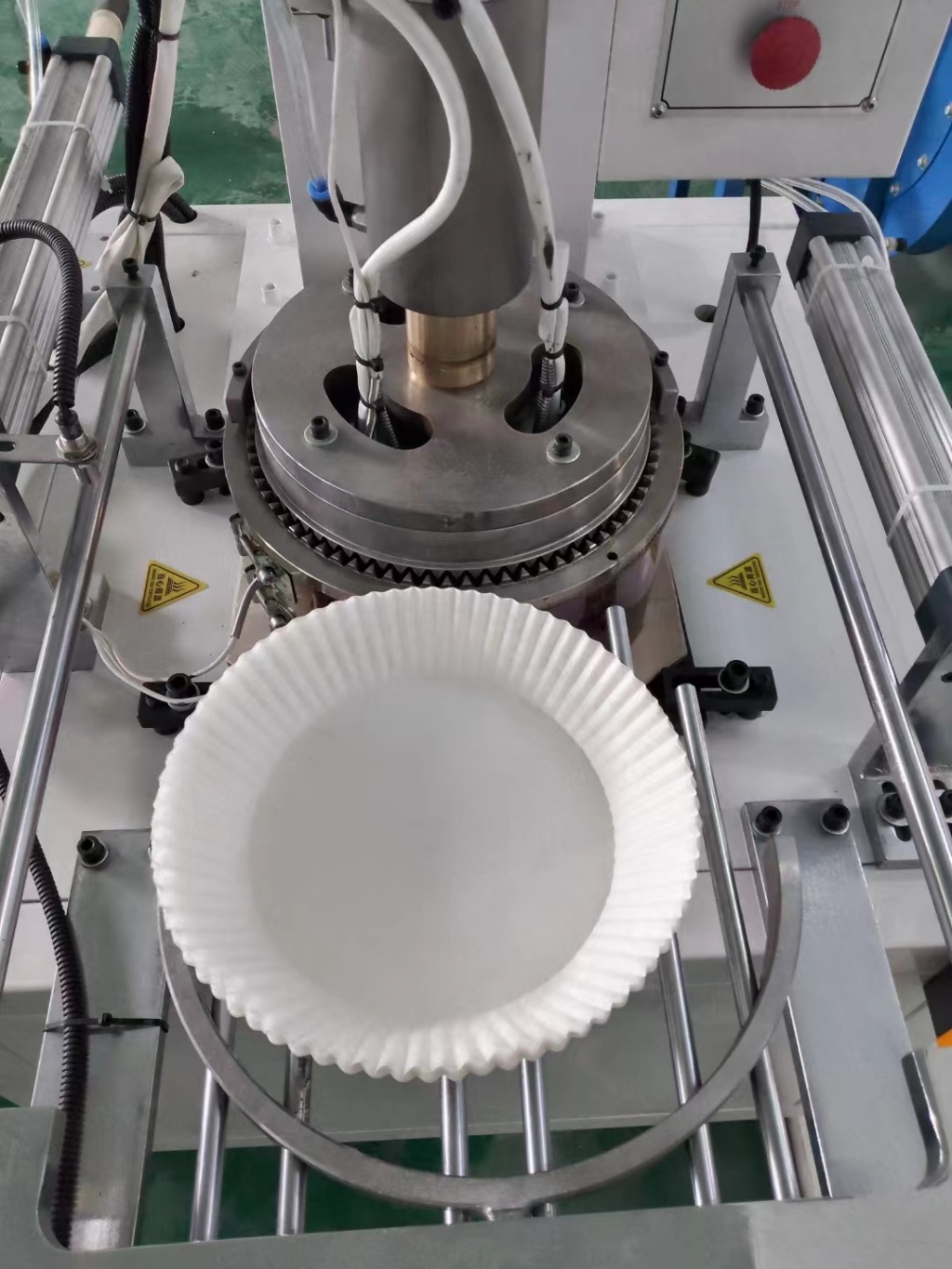

Production

Production Some main uses and characteristics of finished silicone paper.

1. Uses of silicone paper:

a. Silicone paper has the ability to withstand high temperatures, prevent moisture and oil, making it suitable for packaging in the food industry.

b. Its moisture-proof and oil-proof properties allow it to isolate one product from another.

c. It can be used for packaging electronic products.

d. It can be used for automotive foam.

e. It can also be used in the printing industry.

2. Characteristics of silicone paper:

a. Cleanliness: The cleanliness and cleanliness of the surface of silicone paper can be affected by the external environment. In our daily life, there are always some dust, which will affect the cleanliness of silicone paper. It is necessary to improve the environment where silicone paper is located to protect it.

b. Release degree: There is no definite value for the release degree, which depends on the formula of the manufacturer.

c. Peeling force: Some silicone papers have strong peeling force, while others have weak peeling force. We can choose according to our needs.

3. Choosing silicone paper:

1.Based on the characteristics of products produced by manufacturers: The characteristics of the adhesive used in the silicone paper products of different manufacturers are different, and the different properties of the adhesive affect the effectiveness of our use. This is a problem we need to pay attention to when choosing silicone paper.

2. The cost required: The cost of production varies depending on the manufacturer. Generally, silicone paper produced in China is cheaper than imported silicone paper, but the quality of silicone paper produced in China is not as good as that of imported silicone paper. Its release degree is lower, so it is best to use imported silicone paper, otherwise it will cause a large amount of waste of the tape.

3. Production process: In the production process, it is necessary to pay attention to the implementation of two procedures: stamping and cutting. When we encounter the stamping and cutting operation of silicone paper, we must first check whether the thickness of the silicone paper meets the requirements. Otherwise, some low-weight silicone paper will be difficult to achieve if it is subjected to stamping operations.

Some main uses and characteristics of finished silicone paper.

1. Uses of silicone paper:

a. Silicone paper has the ability to withstand high temperatures, prevent moisture and oil, making it suitable for packaging in the food industry.

b. Its moisture-proof and oil-proof properties allow it to isolate one product from another.

c. It can be used for packaging electronic products.

d. It can be used for automotive foam.

e. It can also be used in the printing industry.

2. Characteristics of silicone paper:

a. Cleanliness: The cleanliness and cleanliness of the surface of silicone paper can be affected by the external environment. In our daily life, there are always some dust, which will affect the cleanliness of silicone paper. It is necessary to improve the environment where silicone paper is located to protect it.

b. Release degree: There is no definite value for the release degree, which depends on the formula of the manufacturer.

c. Peeling force: Some silicone papers have strong peeling force, while others have weak peeling force. We can choose according to our needs.

3. Choosing silicone paper:

1.Based on the characteristics of products produced by manufacturers: The characteristics of the adhesive used in the silicone paper products of different manufacturers are different, and the different properties of the adhesive affect the effectiveness of our use. This is a problem we need to pay attention to when choosing silicone paper.

2. The cost required: The cost of production varies depending on the manufacturer. Generally, silicone paper produced in China is cheaper than imported silicone paper, but the quality of silicone paper produced in China is not as good as that of imported silicone paper. Its release degree is lower, so it is best to use imported silicone paper, otherwise it will cause a large amount of waste of the tape.

3. Production process: In the production process, it is necessary to pay attention to the implementation of two procedures: stamping and cutting. When we encounter the stamping and cutting operation of silicone paper, we must first check whether the thickness of the silicone paper meets the requirements. Otherwise, some low-weight silicone paper will be difficult to achieve if it is subjected to stamping operations.

Update time:

TOP