Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| Number | Unit-price | Total | |||

| I want to buy: | × | 0.1 | = | 0 |

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

![H~SN0TQ]E`9J)H8UEJ7T5[R](https://cbu01.alicdn.com/img/ibank/O1CN01irfjd124j9ydSuTPg_!!2261347426-0-cib.jpg?__r__=1667371532957)

![]39TQM61E2B3%C85@MKG}K5](https://cbu01.alicdn.com/img/ibank/O1CN01NHLc0J24j9yWgX4YT_!!2261347426-0-cib.jpg?__r__=1667371532957)

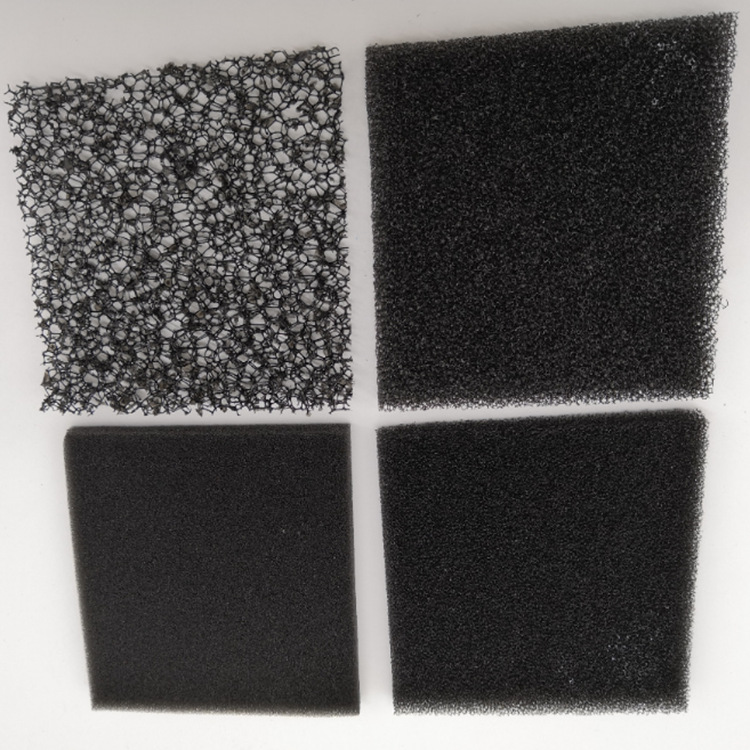

Coarse-pore sponge filter mesh is processed from ordinary open-celled soft foam through a netting treatment. The netting treatment removes the original film or wall film between the foam networks, resulting in a main skeleton mesh structure. This foam plastic has a porosity rate of up to 97%, exhibiting excellent air permeability, good softness, and high mechanical strength. Using netted foam as a filtering material has the advantages of low flow resistance and high filtration efficiency. It can effectively filter particles with a diameter of 15UM. Netted foam has many special applications, such as as a filtering material, fuel tank filler material, and textile processing material, etc. Using netted foam as a skeleton can produce many new functional materials, such as mesh ceramic, mesh metal, and mesh activated carbon, etc. In addition, netted foam is easy to clean and can be reused. It is a multifunctional and economical filtering material, widely used in industrial production, vehicle, and civilian equipment filtering devices. At the same time, it can be made into a filter mesh with excellent flame retardant effect according to customer requirements.

Update time:

TOP