Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

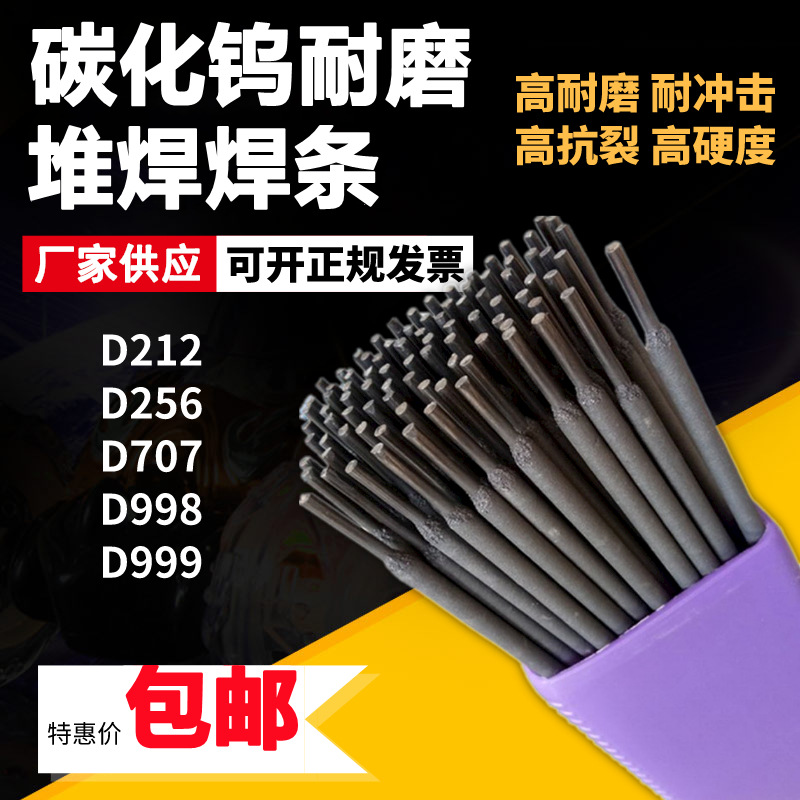

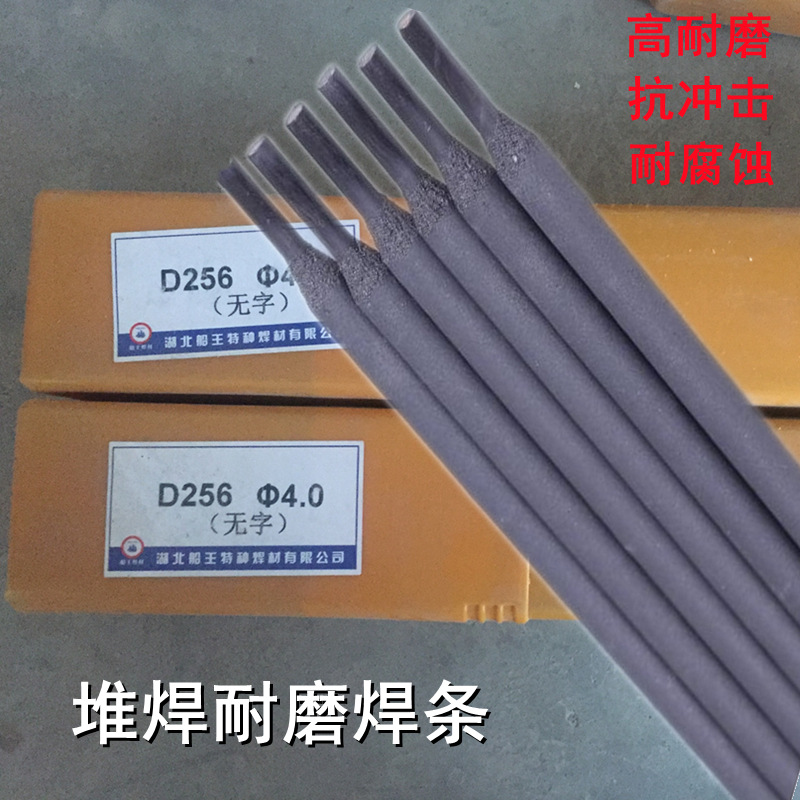

| 3.2mm | ¥0.0 | 49749 kg available |

|

| 4.0mm | ¥0.0 | 49500 kg available |

|

| 5.0mm | ¥0.0 | 49700 kg available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

D276/D277 High Chromium Manganese Steel Resistant to Gas Erosion Weld Wire

Model: EDCrMn-B-16/EDCrMn-B-15

Explanation: The low hydrogen potassium type high chromium manganese steel wear-resistant welding wire is designed for gas erosion resistance. It can be used with direct current reverse polarity. The D276 wire is dual-use, capable of both AC and DC welding (with an AC empty-carriage voltage not less than 70V). The weld seam can be processed to harden, has good toughness and resistance to gas erosion, and exhibits excellent anti-cracking properties.

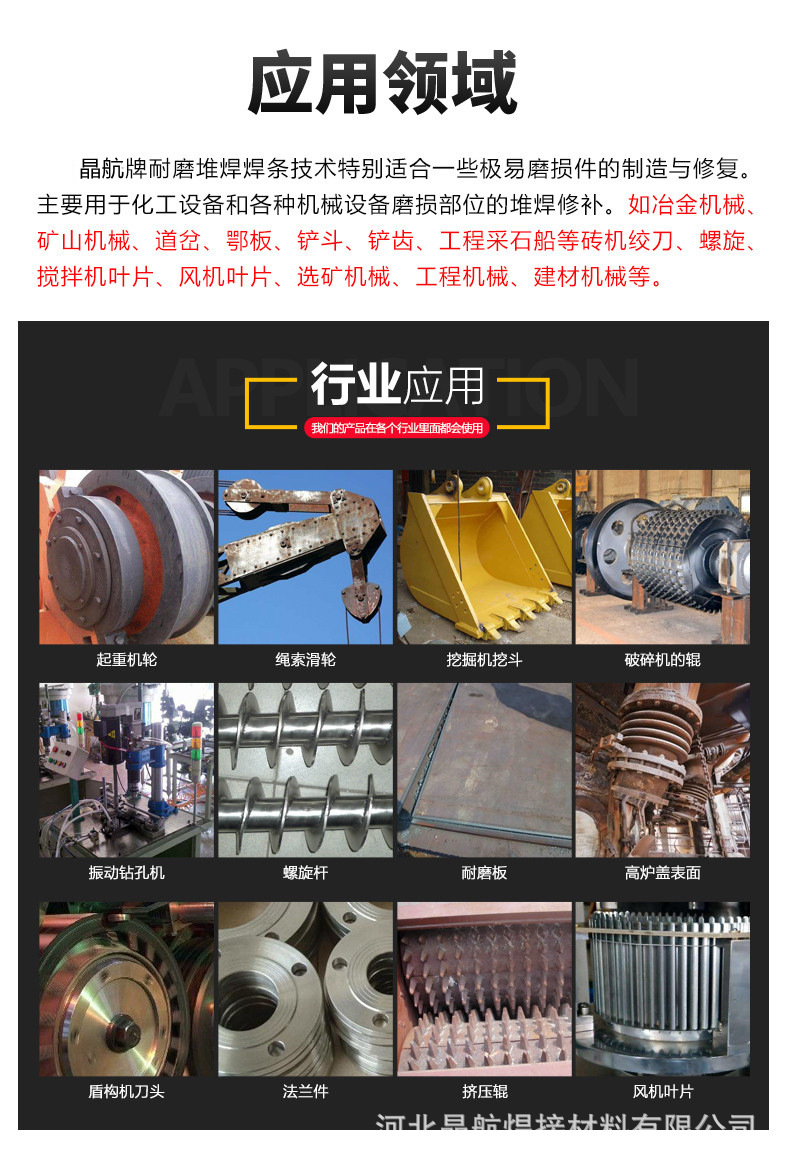

Application: Used for welding parts of hydroelectric turbines damaged by cavitation, such as the guide vanes of hydroelectric turbines, etc. It can also be used for wear-resistant and high-toughness high-manganese steel welding, such as railway turnouts, spiral conveyors, bulldozer blade plates, grab buckets, and crushing blades.

Fusion Coated Metal Chemical Composition

C ≤ 0.8, Si ≤ 0.8, Mn 11-16, Cr 13-17, Other ≤ 4

Weld hardness HB: ≥210

Update time:

TOP