Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| Number | Unit-price | Total | |||

| I want to buy: | × | 155.0 | = | 0 |

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

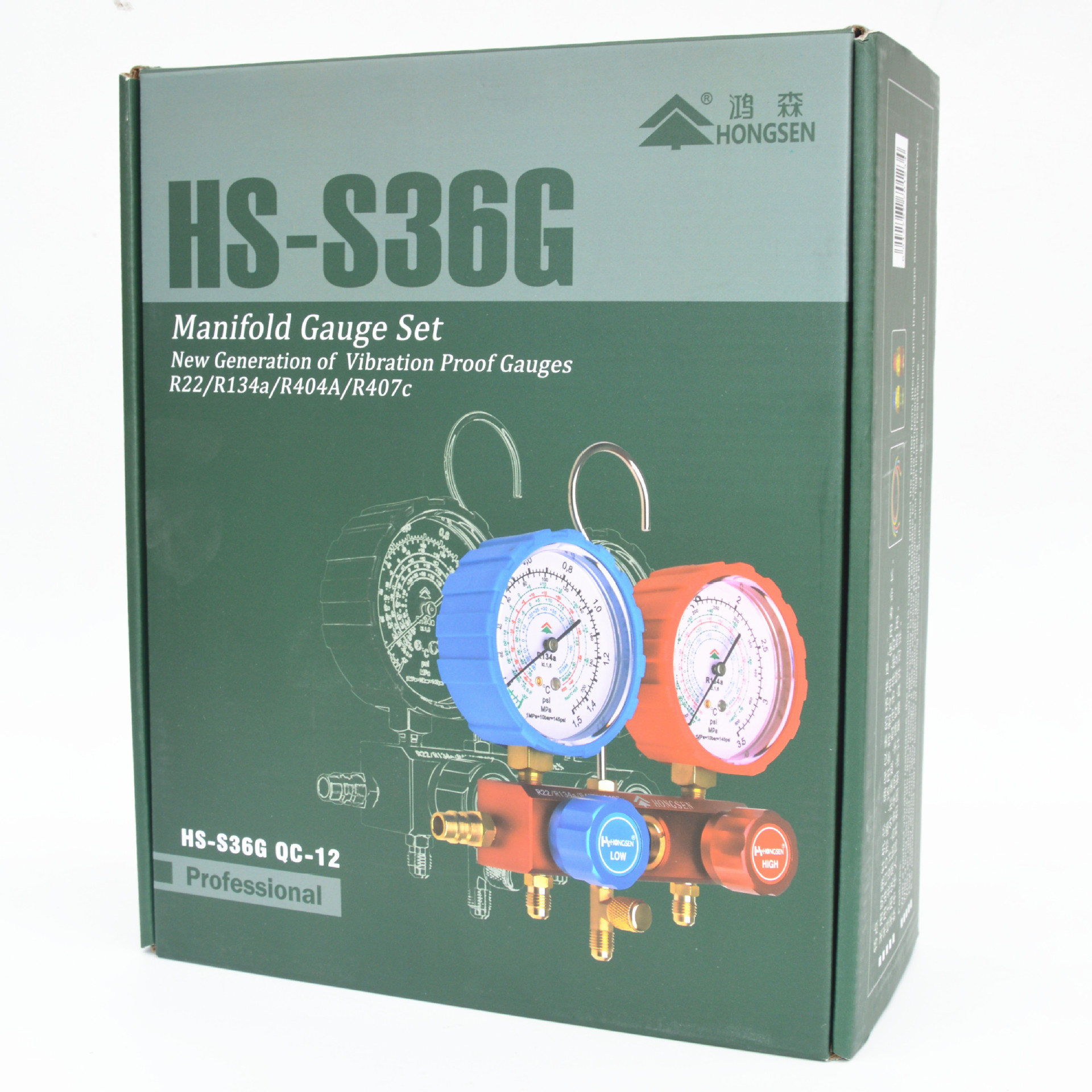

Product Features

· High-quality aluminum alloy valve body

·Special soft rubber protection cover·Ergonomic structure for the hand wheel design

·Precision Pressure Gauge

· Durable product quality

Instruction Manual

Before connecting to the system, please check if the pointer of the pressure gauge is at zero. If not, adjust the setting screw on the pressure gauge to set the pointer to zero.

System Connection

First, close the high and low pressure valves.

Low-pressure interface with a blue tube, low-pressure quick coupler, and system low-pressure phase connection and locking;

High-pressure interface with a red tube, a high-pressure quick coupler, and a system high-pressure phase connection and locking;

The filling interface is connected to the yellow pipe and the vacuum pump and tightened.

System vacuum or recovery(Note: This step must select the appropriate vacuum pump or recycling machine according to the system pressure to ensure system safety and energy saving.)

Complete the above connection, and then turn on the vacuum pump or the recovery machine;

Open both high and low pressure valves at the same time, and then (open the quick connectors for high and low pressure), at this point, the system begins to vacuum or recover;

Check the system for vacuum after a certain period of time (approximately 10-30 minutes) (if the system is not vacuumed, check for any leaks and repair them before re-pumping).

Close the high and low valves simultaneously, and finally turn off the vacuum pump or the recycling machine.

Maintain pressure for 3-5 minutes to check for any leaks in the system.

System Refill Refrigerant

Connect the yellow tube to the refrigerant bottle.

First, open the refrigerant bottle (with the cap facing up), then open the air valve on the gauge set to vent the air from the yellow air tube, and then invert the refrigerant bottle and place it properly;

To the high-pressure valve, add refrigerant to the prescribed amount (according to the manufacturer's charge amount for each system) and close the high-pressure valve. At the same time, place the refrigerant bottle upright.

Confirm the refueling effect

Turn on the system first;

Check the system's high and low pressures after a certain time (approximately 5 to 10 minutes) to ensure they are normal (refer to the system manual). If the pressure is insufficient, slowly open the low-pressure valve while the system is running (strictly prohibit opening the high-pressure valve), add the appropriate amount of refrigerant (the steel bottle should be placed in a positive orientation), and then close the low-pressure valve. After re-detecting, if the pressure is too high, you should shut down the steel bottle, slowly open the high-pressure valve, discharge the appropriate amount of refrigerant from the gas valve core of the gauge group (at this time, you should be aware of the risk of refrigerant injury), and then close the high-pressure valve. Repeat the above steps until the system is normal. First, shut down the refrigerant bottle and the high-low pressure quick couplings, discharge the residual refrigerant in the gauge group from the gas valve core (at this time, you should be aware of the risk of refrigerant injury), and then remove the high-low pressure quick couplings (at this time, you should be aware of the risk of high temperature). Remove the refrigerant bottle, the tri-color tube, and carefully store it.

Update time:

TOP