Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| 5356-1.6 (5kg) | ¥245.0 | 38 piece available |

|

| 5356-2.0 (5kg) | ¥235.0 | 37 piece available |

|

| 5356-2.4 (5kg) | ¥245.0 | 39 piece available |

|

| 5356-3.2 (5kg) | ¥245.0 | 39 piece available |

|

| 4043-1.6 (5kg) | ¥245.0 | 40 piece available |

|

| 403-2.0 (5kg) | ¥235.0 | 40 piece available |

|

| 4043-2.4 (5kg) | ¥245.0 | 40 piece available |

|

| 4043-3.2 (5kg) | ¥245.0 | 40 piece available |

|

| stainless steel 304-1.6 (5kg) | ¥165.0 | 50 piece available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Andeli Welding & Cutting - We Only Sell Good Spare Parts!

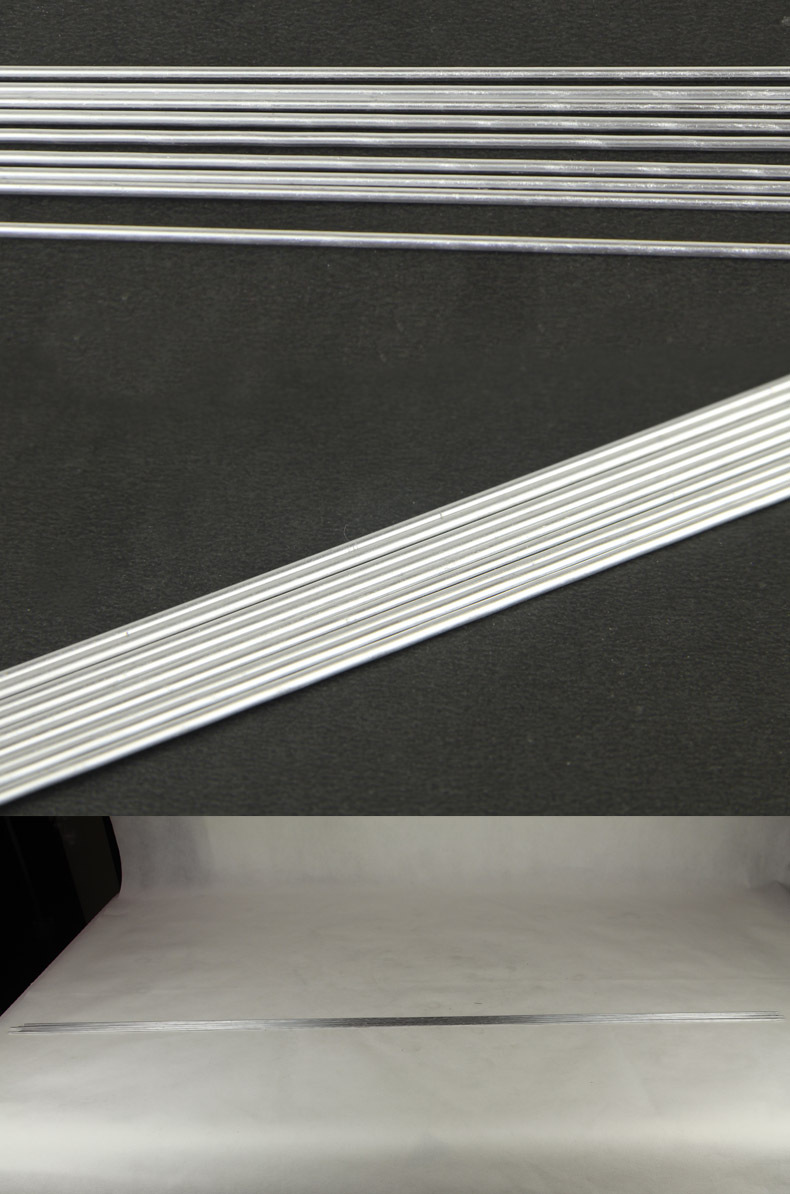

Aluminum silicon alloy welding wire ER4043

Explanation: SAlSi-1 (ER4043) is a series of aluminum and silicon welding wire, suitable for welding 6061 and other 6000 series aluminum alloys, heat-treated alloys of the 2000 series, and cast aluminum. SAlSi-1 (ER4043) contains 5% silicon, which has good fluidity at welding temperatures. The weld metal has excellent resistance to thermal cracking, but its plasticity and toughness are low. After anodic treatment, it will be darker than the substrate, presenting a gray color. When welding 5000 series aluminum magnesium alloys with aluminum silicon alloy, it is easy to form brittle Mg2Si compounds, reducing the ductility and corrosion resistance of the joint. Therefore, this welding wire is generally not used for welding aluminum magnesium alloys. When welding 6061-T6 aluminum alloy with SAlSi-1 (ER4043), the tensile strength of the joint can reach more than 167MPa.

The mechanical properties of the deposited metal -- 6061-T6 aluminum alloy welded with SAlSi-1 (ER4043).

Approximate Melting Range: 573~632℃

Joint anti-tensile strength: above 167MPa

After anodization, the color is gray.

Aluminum Magnesium Alloy Welding Wire ER5356

Performance Features: This product is a 5% magnesium alloy wire, a widely used general-purpose welding material suitable for welding or surface cladding of 5% magnesium cast and forged aluminum alloys. It has high strength and good forging properties, and has good corrosion resistance. This product can also provide good color matching for welding after anodization treatment.

Typical chemical composition: Mg 5, Cr 0.10, (Fe + Si) 0.3, Cu ≤ 0.05, Zn 0.05, Mn 0.15, Ti 0.1, AL balance

Application: Bicycle, aluminum skateboard and other sports equipment, locomotive carriages, chemical pressure vessels, military production, shipbuilding, aviation and other industries.

Update time:

TOP