Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| fzsw-126/10 | ¥480.0 | 2000 only available |

|

| fs-220/100 | ¥450.0 | 2000 only available |

|

| fzsw-66/10 | ¥260.0 | 2000 only available |

|

| fzsw-12/5 | ¥360.0 | 2000 only available |

|

| fqx3-25 | ¥550.0 | 2000 only available |

|

| fxbw-10/100 | ¥25.0 | 2000 only available |

|

| fxbw-66/100 | ¥79.0 | 2000 only available |

|

| fxbw-220/70 | ¥290.0 | 2000 only available |

|

| fxbw-220/120 | ¥320.0 | 2000 only available |

|

| fzsw-40.5/12 | ¥98.0 | 2000 only available |

|

| fzsw-40.5/4 | ¥95.0 | 2000 only available |

|

| fzsw-35/6 | ¥92.0 | 2000 only available |

|

| fsp-220 | ¥430.0 | 2000 only available |

|

| fpq-20/4t | ¥35.0 | 2000 only available |

|

| fxbw-220/120-3 | ¥156.0 | 2000 only available |

|

| fxbw-220/100-2 | ¥360.0 | 2000 only available |

|

| fzsw-10/5 | ¥45.0 | 2000 only available |

|

| fxbw-220/160-3 | ¥296.0 | 2000 only available |

|

| fxbw-35/100 | ¥55.0 | 2000 only available |

|

| fsp-35/0.8-2 | ¥120.0 | 2000 only available |

|

| fxbw-220/100 | ¥350.0 | 2000 only available |

|

| fxbw-110/70 | ¥150.0 | 2000 only available |

|

| fs-110/5 | ¥610.0 | 2000 only available |

|

| fs-110/10 | ¥630.0 | 2000 only available |

|

| fxbw4-10/70 | ¥27.0 | 2000 only available |

|

| fxbw4-24/70 | ¥35.0 | 2000 only available |

|

| fxbw4-35/70 | ¥45.0 | 2000 only available |

|

| fzsw-24/8 | ¥95.0 | 2000 only available |

|

| feg-12/5 | ¥52.0 | 2000 only available |

|

| fpq-10/37 | ¥25.0 | 2000 only available |

|

| fs-35/5 | ¥85.0 | 2000 only available |

|

| fxbw4-35/100 | ¥45.0 | 2000 only available |

|

| fxbw1-220/100 | ¥360.0 | 2000 only available |

|

| fxbw3-220/100a | ¥380.0 | 2000 only available |

|

| xwp2-70 | ¥40.0 | 2000 only available |

|

| fqxsg-25/120-850hh | ¥220.0 | 2000 only available |

|

| fqysg-25/120-850qt | ¥220.0 | 2000 only available |

|

| fqxsg-25/120-890 | ¥240.0 | 2000 only available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Packaging information

CTN Size: 70 × 35 × 35 cm

G.W./CTN:26 kg

QTY/CTN:10 only/carton

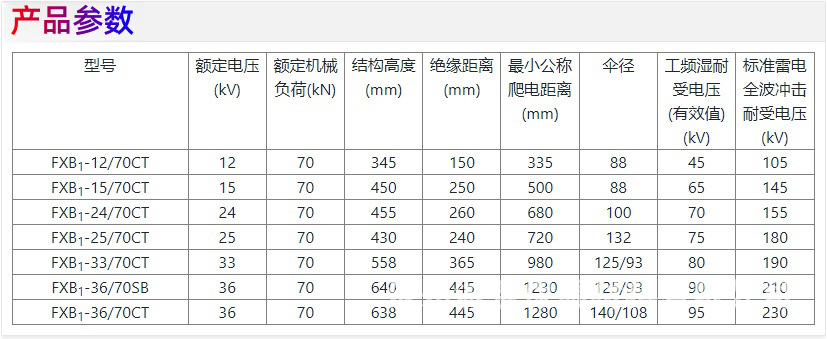

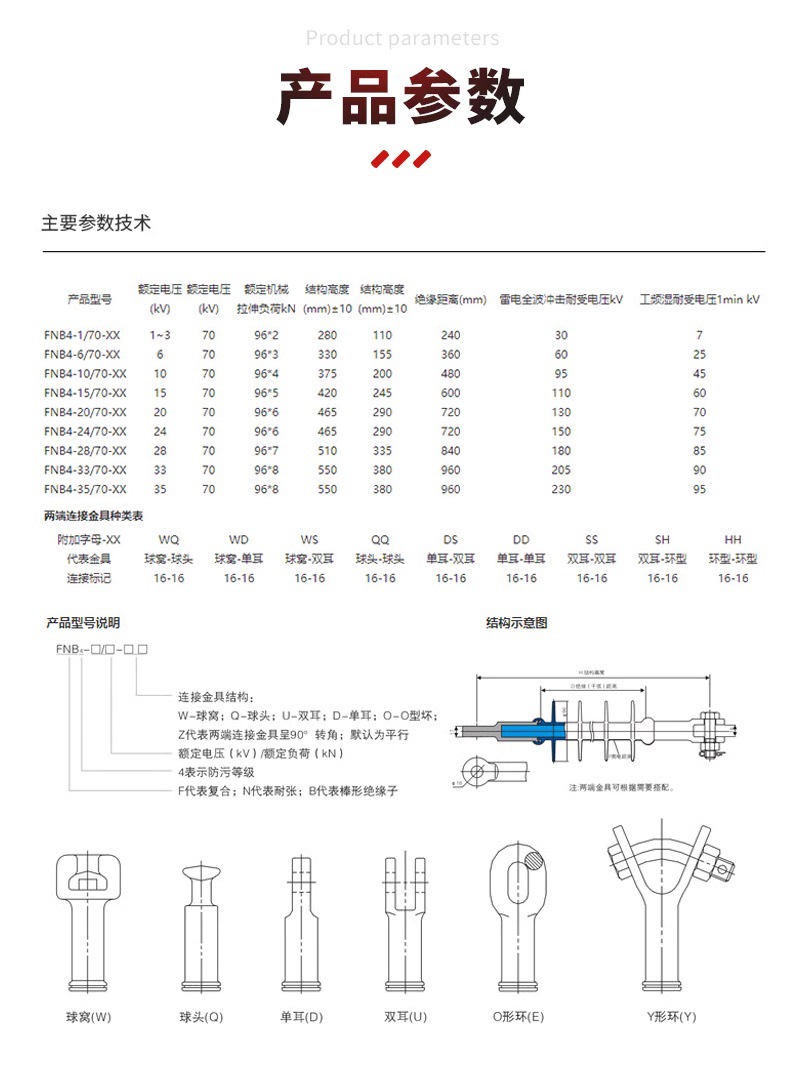

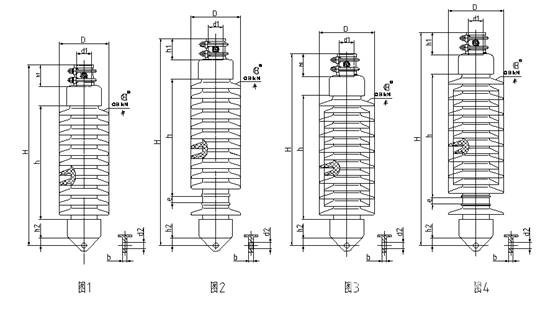

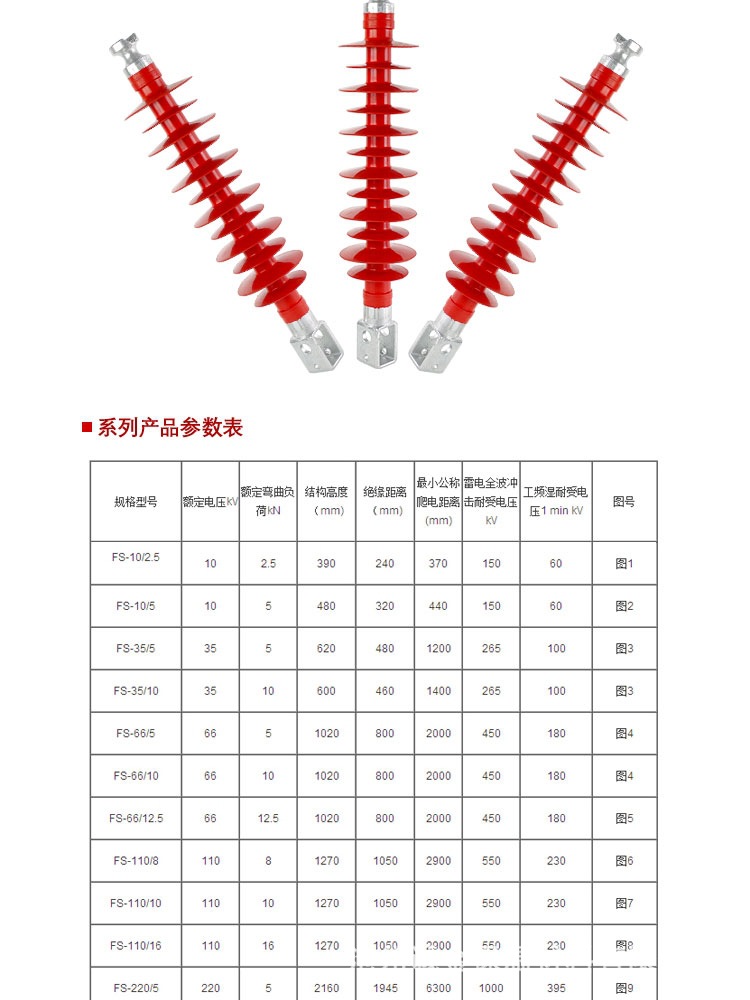

The composite insulator is composed of the insulating core rod, the silicon rubber umbrella sheath, and the connecting fittings.

Insulated Core Rod (full name epoxy resin glass fiber pull-out rod), as the skeleton of composite insulators, plays multiple roles such as supporting the sheath, internal insulation, connecting the two ends of the fittings, and bearing mechanical loads. It has a very high tensile strength. The connection between the fittings and the core rod uses the excellent computer-controlled coaxial constant pressure pressing process, and is equipped with a fully automatic acoustic emission defect detection system, ensuring the reliability and stability of the connection between the fittings and the core rod. The core rod uses ERC high-temperature acid-resistant rod, and the interface between the core rod and the silicon rubber is coated with special coupling agent. The sheath uses the silicon rubber high-temperature and high-pressure one-time integrated molding process, combined with the computer-monitored two-stage sulfurization process, which extends the service life of the product. The production equipment and manufacturing process, complete testing equipment and detection means, ensure that the technical indicators of the product meet the relevant domestic and international standards, becoming the new generation of insulators for high-voltage transmission and transformation lines.

Silicone rubber umbrella sheaths primarily serve to increase the climb distance, shield against rain and snow, protect the core rod and the product's external insulation. They are made from high-polymer silicone rubber as the base material, with additives such as flame retardants, anti-aging agents, coupling agents, etc., which are processed through high-temperature and high-pressure sulfurization. These sheaths have excellent hydrophobic and migratory properties, as well as good corrosion resistance, aging resistance, electrical insulation, and other performance characteristics. They also have a high flashover voltage under pollution and good resistance to breakage. The voltage distribution is uniform, and under the same conditions, the flashover voltage is more than twice that of ceramic insulators.

The end of the composite insulator adopts the maze design principle, with multiple layers of protection and excellent sealing performance, solving the key issue of "interface electrical breakdown" for insulators. The material is made of special steel, and the product quality is excellent.

The following operating guidance for composite insulators is as follows:

Handling and Storage: Composite Insulators should be handled gently to avoid friction and collision with sharp or hard objects such as iron and tools. They should be stored in a dry warehouse and take preventive measures against rodents. At the same time, they should be avoided from contact with oils and petrochemical products.

Lifting and Installation: When lifting insulators, the rope knot should be tied to the end attachment, and it is strictly prohibited to tie it to the umbrella group or sheath. When installing, attention should be paid to adjusting the equalizing ring to be vertically installed from the axis. For open-type equalizing rings, the direction of the two ends should be consistent. It is strictly prohibited to step on the insulator umbrella group, nor should the composite insulator be used as an auxiliary tool for laying lines.

Inspection and Maintenance: Regular infrared inspections are conducted, especially at night or in the early morning or evening when there is no sunlight interference and the humidity does not exceed 70%RH, to reduce interference and improve detection accuracy. If an abnormal temperature rise is detected, it should be dealt with in a timely manner.

Cautions: During installation and use, avoid applying excessive bending or torsional stress to the core rod. Additionally, do not rotate insulators that are already fixed or under load when hanging lines.

The above operation guidance is for reference only. It should be adjusted according to actual conditions when applied.

Update time:

TOP