Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| 21 model grinder | ¥0.0 | 665 piece available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

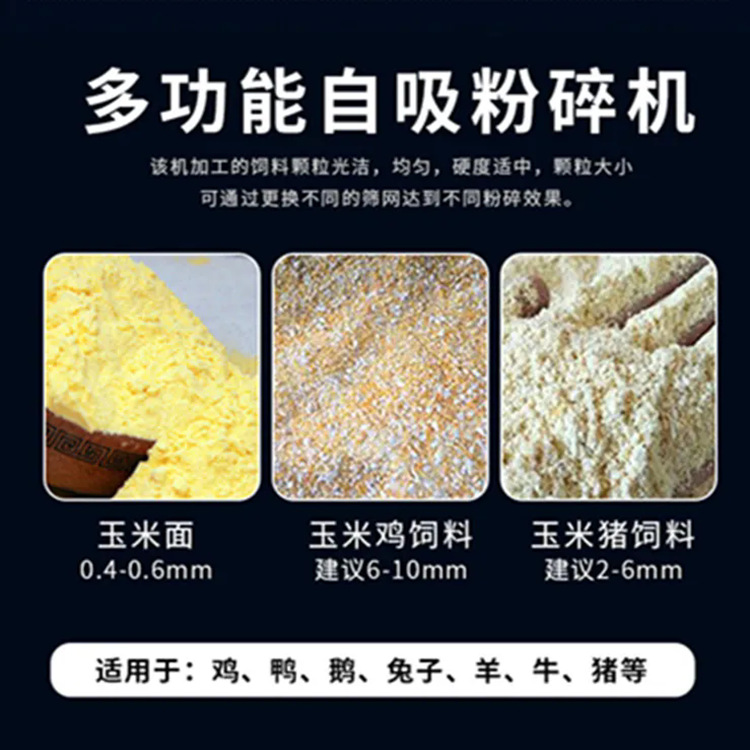

This machine is suitable for the powder industry, including pharmaceutical, chemical, food (such as sugar, sugar, salt, rice, corn, starch, oats, flour, soybeans, peas, beans, mung beans, spices, flavoring, sweeteners, dried fruits, nuts, potato chips, crumbs, cocoa powder, potato starch, coffee, milk powder, onions, dehydrated vegetables, lotus seeds, glucose, oat hulls, fruit shells, ginger, pepper, pepper, wheat, soybeans, star anise, cinnamon, etc. It is a crushing equipment that is integrated with crushing and dust collection continuous discharge.

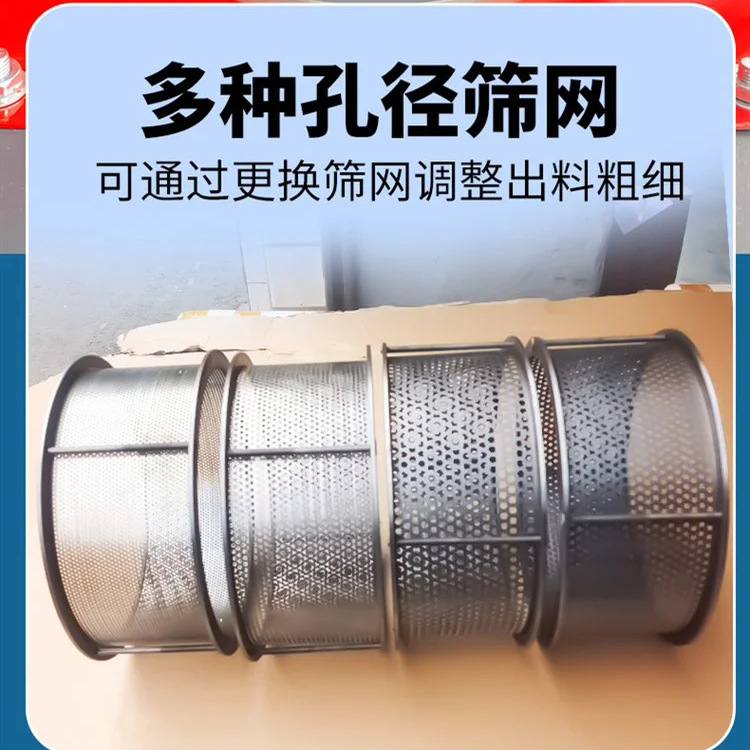

The tooth claw type crusher is mainly composed of six parts: the upper body, the lid, the rotor assembly, the screen, the feeding device, and the frame. The body and the rotor assembly jointly form the crushing chamber, and the rotor assembly is the main working component. The crushing of the material is completed in the crushing chamber. When the material enters the crushing chamber, it is broken into fine powder and paste under the impact and rubbing action of the circular teeth and flat teeth. Under the action of centrifugal force and airflow, it is discharged through the screen holes through the discharge port.

Tooth claw type crusher, the main working parts are the flat teeth on the installed rotor, and the circular teeth can crush various granular raw materials. It is currently the most economically efficient grinding equipment, with numerous advantages such as small volume, light weight, convenient installation, operation, and maintenance, and high production efficiency.

【Disk Mill Product Advantages】:

The crusher is made of cast iron and consists of a common host and the milling, grinding, and feeding processing cores that are matched with the host. The cantilever shaft that is connected to the main shaft of the single-phase motor extends into the host shell. On the cantilever shaft of the grinding machine, on the host shell, and on the components of each core, there are designed interlocking cones, cone holes, threads, and screw holes. The entire processing machine is supported on the machine base. It integrates milling, grinding, crushing, and feeding processing machines, with a very simple, compact, and lightweight structure. It is convenient to use and flexible, with multi-functionality, suitable for rural and small-scale grain and feed processing operations.

【Teeth Claw Type Crusher Working Principle】

When the crusher starts working, the tooth plate inside the main body will begin to rotate at high speed under the drive of the motor. At this time, the material will be uniformly entered into the crushing chamber from the feed hopper, and the high-speed rotating tooth plate will take the material to do the rotating crushing work. The main reliance is on the relative up and down teeth of the tooth plate to grind and strike, and the degree of crushing. The finished material will be discharged from the bottom of the drum to complete the crushing work.

【Tooth Plate Crusher Installation and Commissioning】:

1. The crusher can be fixed on a cement foundation or on a machine frame made of steel or hard wood. The length of the V-belt can be determined according to the distance of the fixed machine frame.

2. When using a tractor as the power source, an additional frame can be made to install the belt wheels required for the matching diesel engine.

3. Regardless of the power source used, it is important to pay attention to the speed of the crusher. Adjust the belt pulleys to meet the requirement of 4200-4600 rpm for the crusher.

4. The circuit is reliable, and the working voltage is stable.

5. Before starting the machine, check if the belt tension is appropriate, the speed is reasonable, whether there is lubrication at the lubrication points, and whether the screws at all parts are loose. Only after any abnormal phenomena are eliminated can the machine be started. Let the machine run for 2-3 minutes without material, and only after it is normal can the material be fed for work.

Update time:

TOP