Product

Multi-stage pressurization

Oblique tooth design with high performance

Low wear, low noise

High oil yield

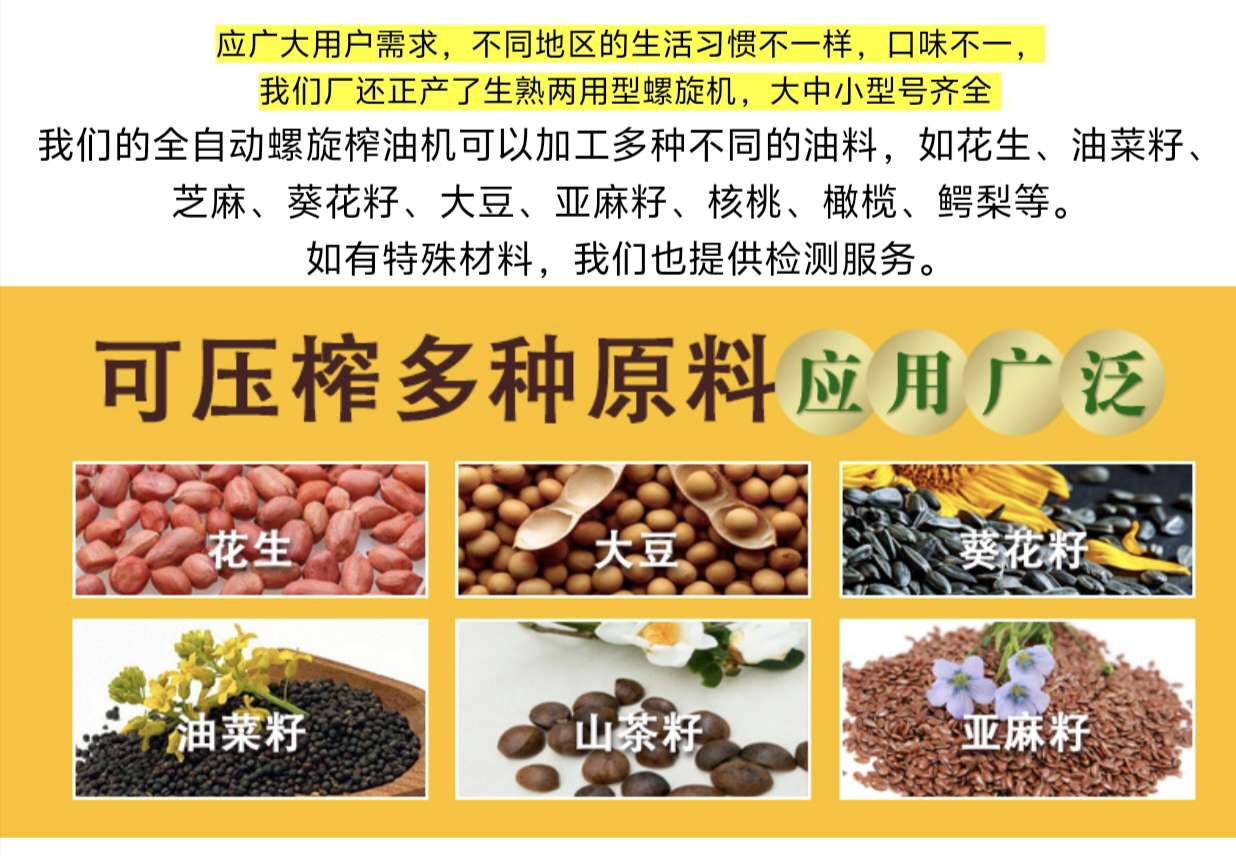

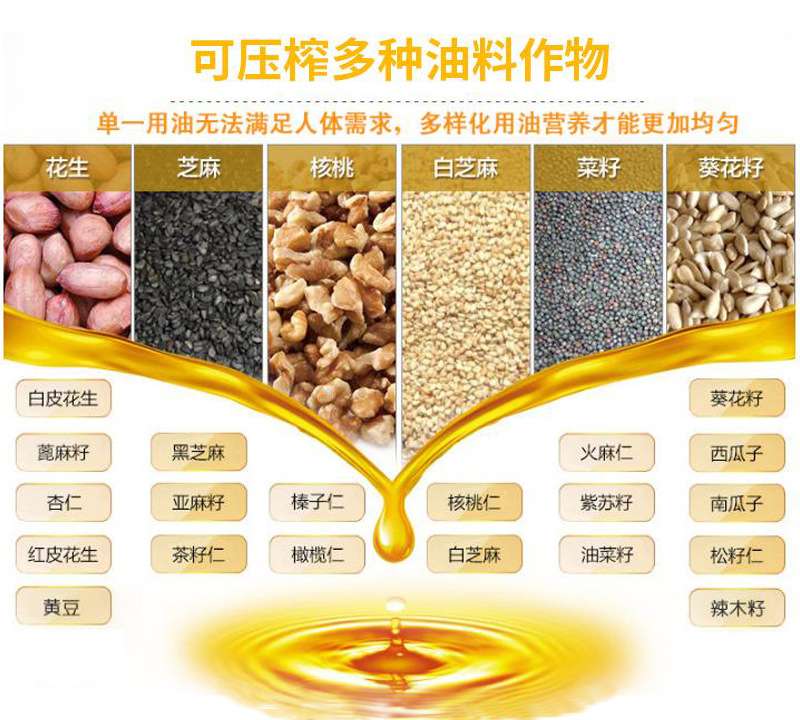

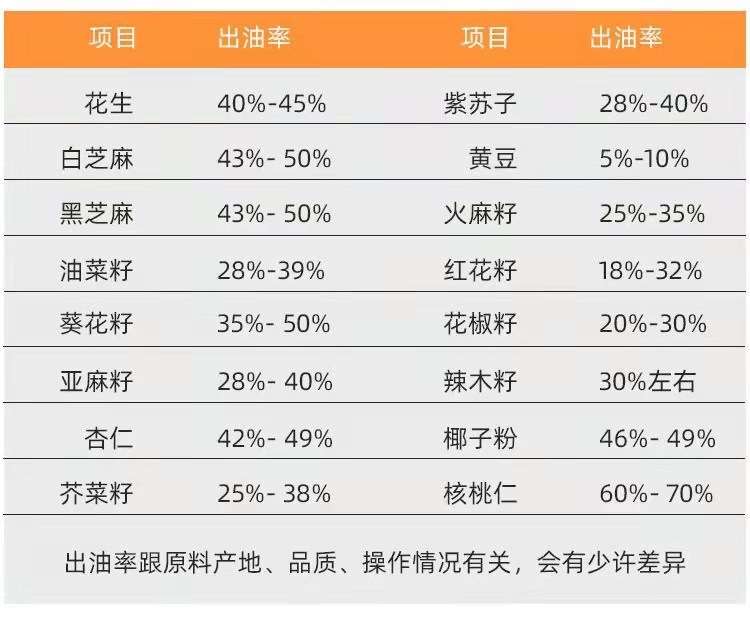

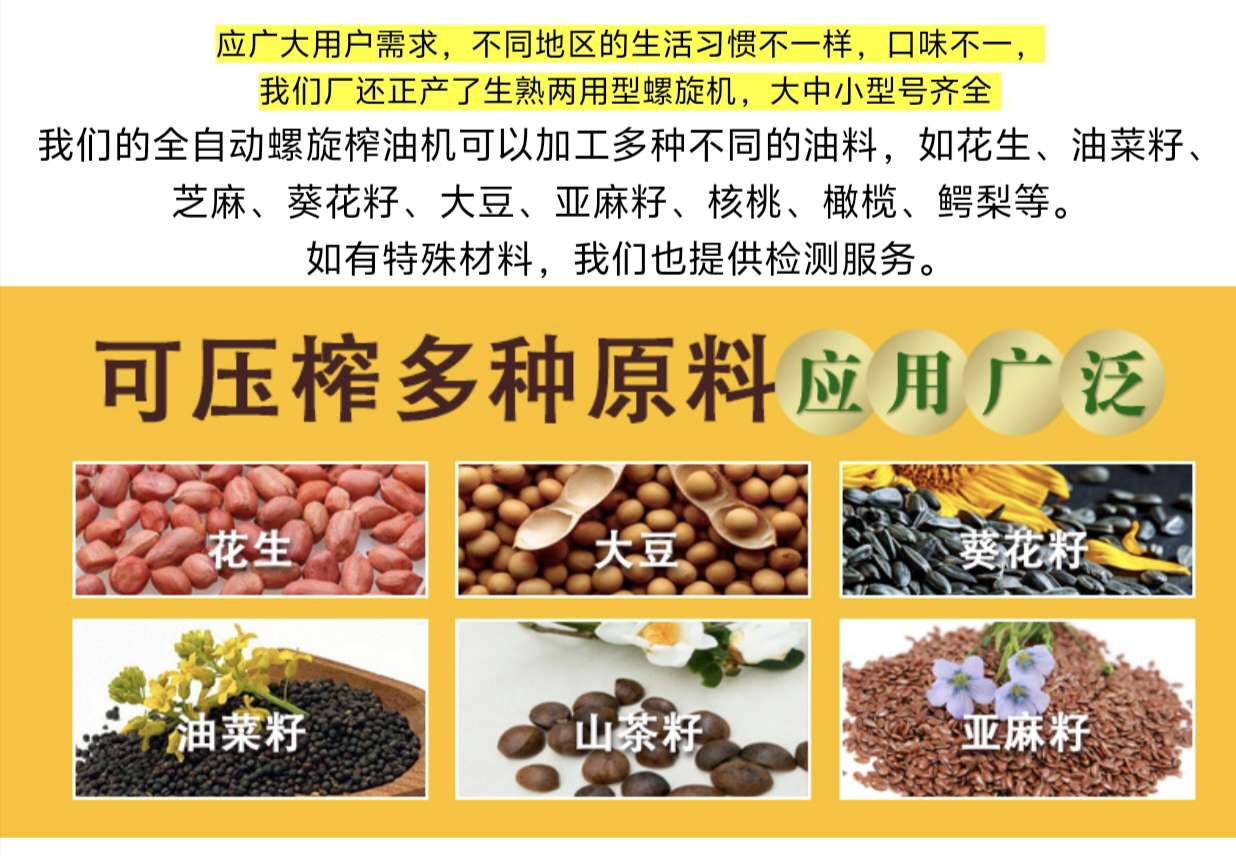

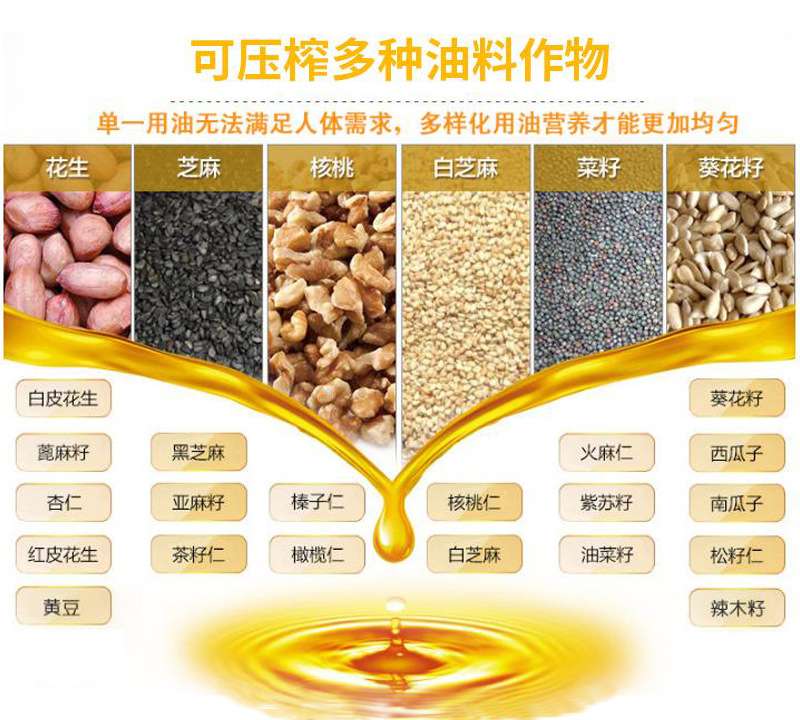

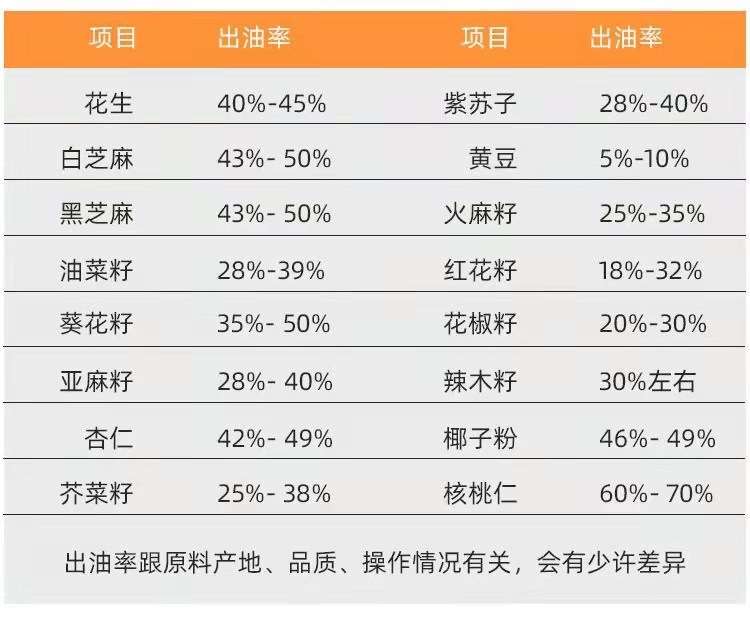

Can be pressed from various raw materials

High yield, high oil extraction rate

C. Oil is transparent

Pure and transparent oil extraction

Convenient and time-saving oil filtration

D.薄饼王

Adjustable thickness of the doughnut

Thin Crust Profit High

Full-automatic oil extraction machine 50-type spiral oil extraction machine, complete cooking and frying equipment for oil mills, small-scale rapeseed oil extraction machine

Workflow:

1. Cold Pressing: Peanut kernels are high-oil content oilseeds with an oil content of about 40-50%. It is important to control the moisture content of the oilseed during cold pressing. The optimal moisture content should be around 4-5%. When cold pressing, add about 30% of dry cake to the mixture, and wait until the temperature rises to 100 degrees to begin the pressing. During the pressing process, if the cake is not well extracted, there may be leakage of residue or oil. This may be due to excessive moisture in the oilseed, insufficient mixing of the cake, or uneven distribution. Sometimes, it may also be due to insufficient machine temperature.

2. Hot Pressing: During hot pressing, attention should be paid to:

Master the steaming and frying technology. During the steaming and frying process, the water content of peanuts should be between 1-2%, and the temperature should reach 120-.

130 degrees can be used for pressing.

The main steps of the spiral production line

Ingredients