Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| Number | Unit-price | Total | |||

| I want to buy: | × | 7650.0 | = | 0 |

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

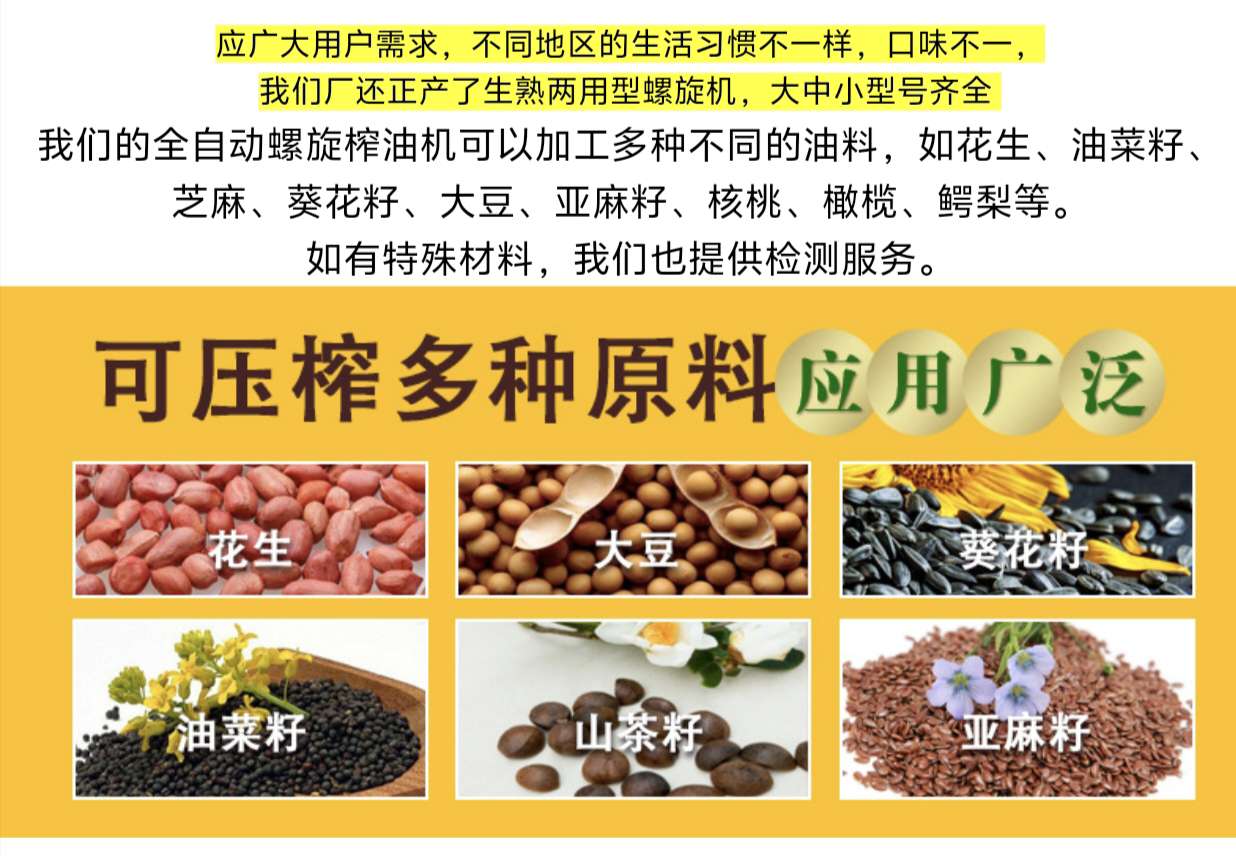

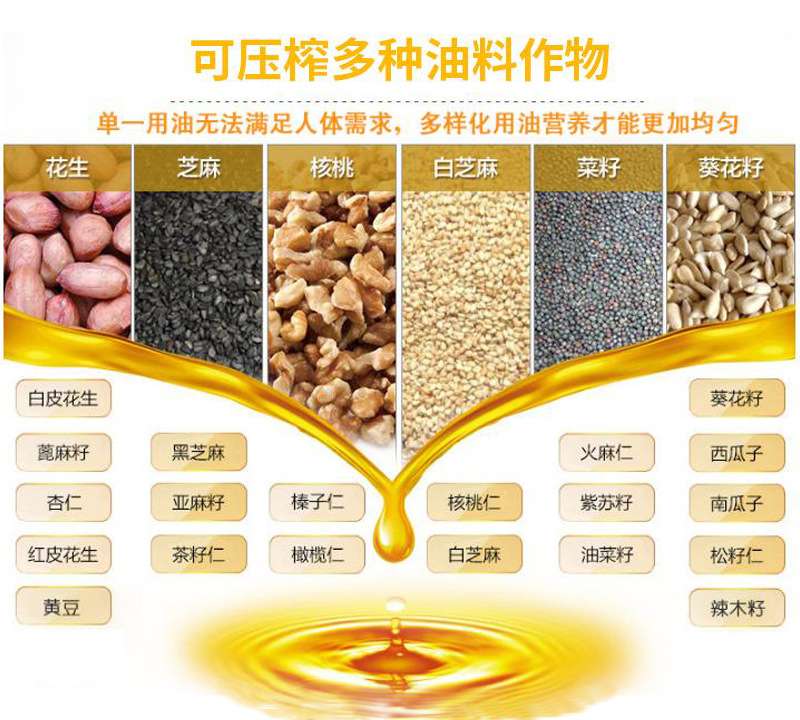

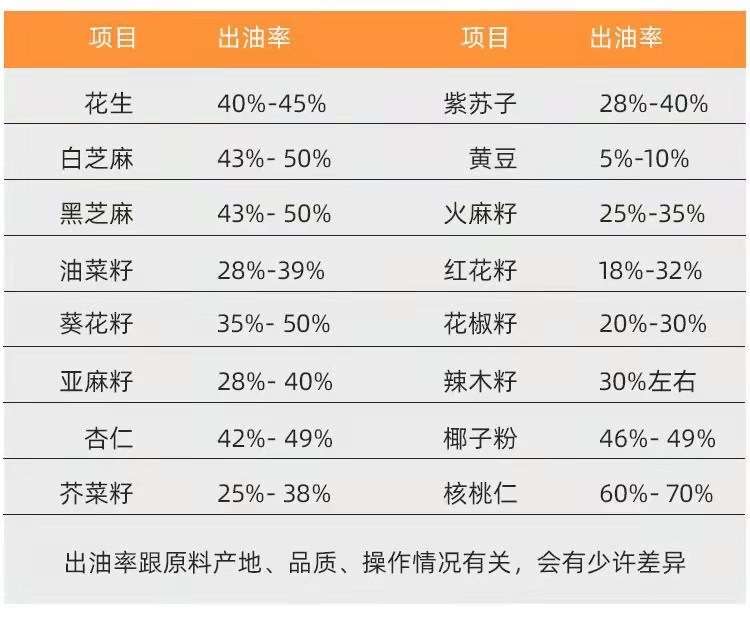

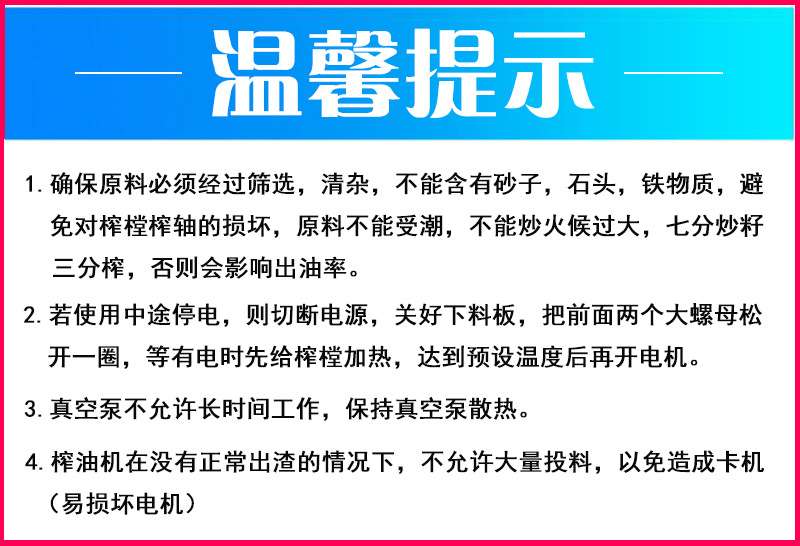

Full-automatic oil extraction machine 75/110/125 model spiral oil extraction machine complete fryer equipment oil mill small-scale rapeseed press machine Workflow: /Take peanuts as an example/ Cold press: Peanut kernels are high-oil materials with an oil content of about 40-50%, and the water content should be controlled at about 4-5% when cold pressing. When cold pressing, add about 30% of dry cake and mix it well. When the temperature reaches 100 degrees, you can press it. If the cake is not good, it is sometimes due to the high water content of the oil material, sometimes due to insufficient mixing of the cake, or uneven, sometimes due to the temperature of the machine not reaching the desired level. Hot press: When hot pressing, pay attention to master the steaming and frying technology. The water content of the peanut kernels should be 1-2% when steaming and frying, and the temperature should reach 120-130 degrees before pressing. The main steps of the spiral production line

Full-automatic oil extraction machine 75/110/125 model spiral oil extraction machine complete fryer equipment oil mill small-scale rapeseed press machine Workflow: /Take peanuts as an example/ Cold press: Peanut kernels are high-oil materials with an oil content of about 40-50%, and the water content should be controlled at about 4-5% when cold pressing. When cold pressing, add about 30% of dry cake and mix it well. When the temperature reaches 100 degrees, you can press it. If the cake is not good, it is sometimes due to the high water content of the oil material, sometimes due to insufficient mixing of the cake, or uneven, sometimes due to the temperature of the machine not reaching the desired level. Hot press: When hot pressing, pay attention to master the steaming and frying technology. The water content of the peanut kernels should be 1-2% when steaming and frying, and the temperature should reach 120-130 degrees before pressing. The main steps of the spiral production lineUpdate time:

TOP