Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Price Negotiable

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Pujiang Bochang New Material Technology Co., Ltd 14yr.

Contacts:KuangqunhuaChat

Mobile:86-15657905600

E-mail:138552828@qq.com

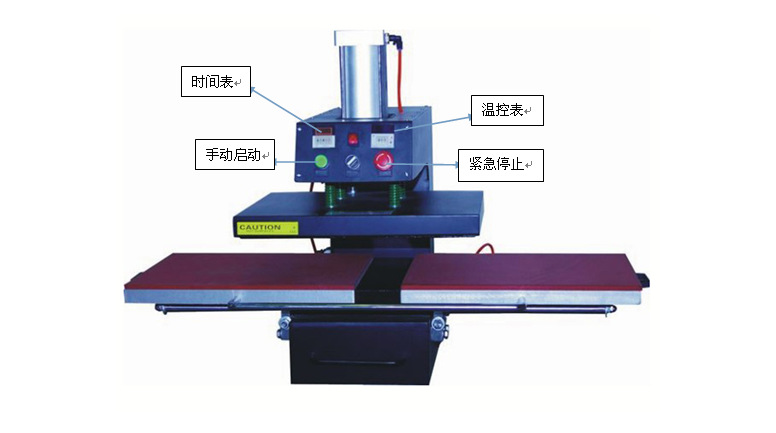

Pneumatic Double Station Heat Transfer Machine User Manual

Structure Diagram

Section Two: Main Uses:

Three, Product Features:

Electronic digital temperature display and constant temperature control, high accuracy.±2"℃" is the symbol for Celsius temperature scale.);

The heating system uses imported aluminum alloy casting to conduct heat, which saves electricity, maintains uniform temperature, and has a small temperature coefficient.";

Electronic digital time control, high accuracy, beautiful appearance.

Pressure Adjustable at Will

Section 4: Technical Specifications:

Power: 3500W

Voltage: 220V

Temperature range: 0-399°C

Time Range: 0--999Sec

Heat Transfer Area: 40*40Centimeter

Steps for Operation

1and1Connect the compressor joints and open the air pressure. Adjust the pressure regulator from 6pB to (4pB-6pB), so that the heating plate rises.

2Connect the compressor connector as specified, open the air pressure, and adjust the pressure gauge.4pB-6pB)Please provide the Chinese text you want to translate, and I will translate it into English for you.Make the heating plate rise.

3Turn on the power, open the main power switch, and the indicator light will turn on immediately.

4Adjust the time and temperature as needed.(Details on the last page.)

5Adjust the temperature and time, and wait for the machine to heat up.

6After the temperature is warmed up, the temperature gauge will light up with a small green light.

7Place the clothes flat on the silicone pad, then place the heat transfer paper (note the front and back of the heat transfer paper), push the surface to the heat pressing position, press the start switch, press the item flat, place the heat transfer paper, then place the high-temperature cloth, start the switch, and the heat transfer begins, with a countdown to the time.

8Complete, the heating plate automatically rises, pulling out the work surface.

9The heated items.If the hot transfer paper is cold-peeled, please wait for 5-10 seconds before tearing off the transfer paper. If the hot transfer paper is hot-peeled, please immediately tear off the transfer paper after the transfer is completed.

10After the trial printing is successful, you can rotate the button to the semi-automatic position. After placing the hot stamping item, as long as you move the handle to the exact location above the item, the hot stamping will automatically begin. In case of an emergency, you can press the button to stop immediately. After the emergency stop button is reset, you can continue with the hot stamping.

Sixth, Maintenance Matters:

1Pressure: Inadequate uniformity. First, measure the four edges of the heating plate from the bottom plate to ensure they are consistent. If they are not, you can adjust the central four threaded rods on the heating plate by tightening the "downward" nut. To increase the pressure, tighten the nut downward, and to decrease the pressure, tighten the nut upward. The pressure should not be too high or too low (typically, the pressure should be "").4KG-6KG)Please provide the Chinese text you want to translate, and I will translate it into English for you.Adjust the regulator valve on the filter to the up position.plusIncrease pressure in the direction.-Reduce the pressure or check the air compressor pressure to ensure it is within the normal range (typically, the air compressor pressure should be ...).6KG-8KG).

2When the base plate is in place, if the time is not displayed, check the proximity switch to ensure that the distance is appropriate and adjust it to be lower than4Millimeter, time up, the heating plate is not coming down, check the circuit.

3Temperature: Adjust to the set temperature, no heating, no temperature control, check the temperature control gauge, contactor, and the heating plate circuit for good contact and electrical component faults.

Attention:

The entire machine must have a suitable and reliable grounding line.

Successful heat transfer requires the coordination of correct timing, temperature, and pressure. The thickness of the clothing, the material, and the type of heat transfer paper all affect the heat transfer effect. Before mass production, various heat transfer papers should be tested with a small sample.

The temperature and time required for heat transfer are as follows:

Cotton clothes: 180-220 degrees, 25 seconds

Polyester clothes: 180 degrees, 15 seconds

Pearlescent board: 180 degrees, 120--180 seconds

Metal pendant: 180 degrees, 60 seconds

Mouse pad: 180 degrees, 15 seconds

Ceramic Plate: 200 degrees, 180 seconds

Keychain: 180 degrees, 100 seconds

Ceramic: 180-220 degrees, 180 seconds

Update time:

TOP