X Email Mobile

| EXW Price: |

|

| Main Products: |

High frequency,blister machine,welding machine and accessories |

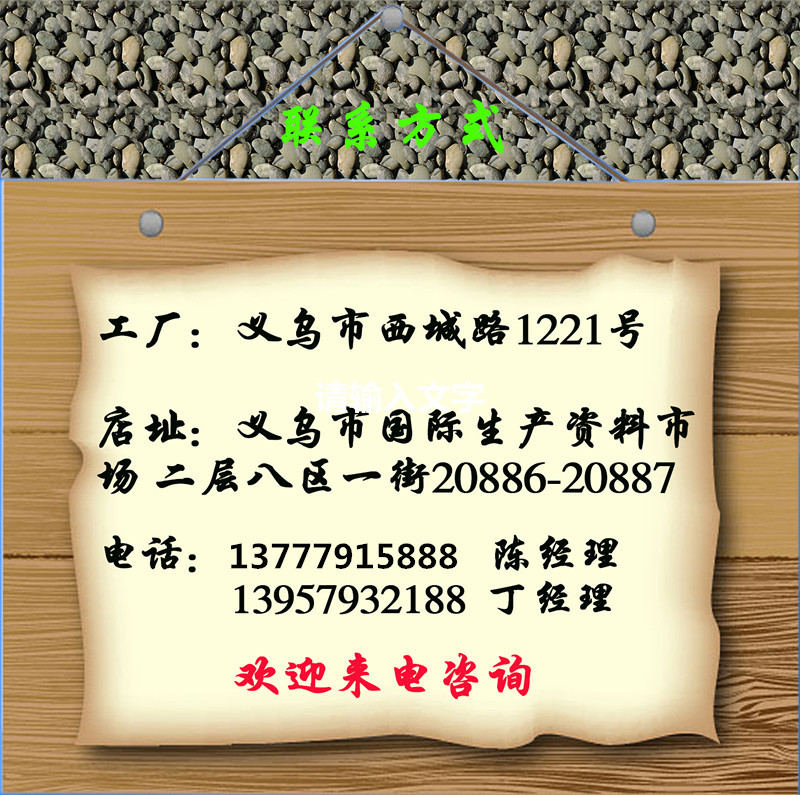

| Contacts: | Ding JianChat |

| Mobile: | 86-13777915888 |

| E-mail: | |

| WeChat: | 13957932188 |

| Address: | 20886 , 2 F, Yiwu Production Material Market. |

| Address: | Jinhua Light Luxury Flower Household Supplies Co., Ltd., Zhengzhai Town, Pujiang County, Jinhua City, Zhejiang Province |

Blister forming machine, blister machine, high speed machine

important note:

1. Vertical pull tab design: pull tab is fast, uniform and stable, which shortens the occupation time of pull tab, is more adaptable to environmental protection materials and reduces power consumption to ensure the molding quality of products.

2. Independent grouping temperature control: special dense plane far-passing external ceramic heating element device is adopted, with uniform temperature, which is 50% higher than that of traditional machines.

3. Electrothermal furnace closed heating is adopted to make the heating more uniform and reduce the loss of heat energy, and manual switch is attached to control the vertical lifting of electric furnace, which is conducive to controlling the product quality in the production process, thick film can be heated by upper and lower electric furnaces (customized by customers) to speed up the heating time and improve the production speed.

4. This machine is equipped with vibration knockout, which is not easy to deform and demoulding for difficult products.

5. Double-row pointed needle chain drive ensures accurate and stable high-speed operation. It is equipped with adjustable width device to make the machine make maximum use of film and reduce waste.

6. The whole machine is equipped with water transport cooling device and high-speed cold water spray to speed up the molding speed and ensure the molding quality, and the production speed is twice as fast as that of the traditional machine.

7. Built-in secondary vacuum makes difficult products easier to form, improves product quality and reduces rejection rate.

8. The whole machine adopts all imported electrical appliances and pneumatic components of international famous factories, which are absolutely reliable in quality, safe and durable.

| Product description: |

1. Molding width: 460mm-660mm(510mm-710mm sheet) |

Main applications: plastic packaging industry (blister packaging, plastic, battery, toys, gifts, hardware, household appliances, electronics, stationery, decoration); Food packaging industry (fast food box, fruit tray, cookie box); pharmaceutical Industry (pill packaging, tablet packaging); Industrial cooling tower cooling water flow deflector, etc.; Decorative three-dimensional relief pattern, plastic ceiling, wall plate, automobile materials, sanitary equipment and other manufacturing industries.

Mechanical features:1. The computer LCD touch screen control system is easy to operate and start up. The technical requirements for employees can be reduced to ensure the quality and quality of the whole machine;

2. Using Germany Siemens water circulation vacuum pump, the vacuum channel output is stronger and the forming time is extremely short, which greatly improves the production speed of the product;

3. Electronic digital temperature control is adopted to make the temperature more accurate; The power consumption is lower. The heating brick imported from Germany can adjust the local temperature arbitrarily, making the stability control more flexible, accurate and energy-saving;

4. Save raw materials, form high quality, reduce defective products, and save blister machine of film materials than traditional chains;

5. Equipped with cold water machine and spray air cooling system rapid cooling device, non-Vibrative and residual air to speed up the production speed;

6. The feeding transmission system adopts Japanese server · frequency conversion technology to electronically control pull tab, powerful horsepower, accurate length of pull tab (accurate to ± 2mm), adjustable speed and length, accurate, fast and stable, it also has the function of film material exit to avoid film waste. Can adapt to the processing technology of different raw materials;

7. It can prevent problems such as uneven thickness, excessive fire, deformation, deduction, APET whitening, and water lines;

8. The PLC control system of LCD touch screen can record the production statistics of batch production products or each roll of film; 9. The mold changing time is greatly reduced, and it only takes a few minutes to complete the mold changing, the lower mold plate can be raised and lowered independently, and the mold with different adjustable height can be widely applied. It is easy to demoulding, and is equipped with multiple demoulding functions such as vibration mold and repeated top mold; 10, this model developed by the new product has been tested and produced by professional blister manufacturers, with excellent quality and stable performance, and can completely replace imported machines of similar equipment;

mechanical parameters:

| model | JL8-680 |

| molding width | 460MM ~ 660mm |

| forming length | 0 mm~1200mm |

| forming height | +10 "~-7" |

| production efficiency | 180~360 sheets/hour |

| vacuum pump | 4kw |

| siemens power supply | 380V/220V/50Hz (three-phase four-wire) |

| electric Furnace power | 20 KW |

| air pump required | 4 KW |

| mechanical dimension | L4480 × W3300 × H2800mm |

| mechanical weight | 2100kg |

TOP

Items have been added to the Inquiry Basket

There are items in the inquiry basket