X Email Mobile

| EXW Price: |

|

|

ZIQI NEW MATERIAL 13yr. |

|

| Main Products: |

Nail jewelry nail accessories beauty ingredients cosmetics materials novelty toys educational toys luminous toys Glitter pearl powder luminous powder |

| Contacts: | Chen JiexiongChat |

| Mobile: | 86-13735600144 |

| E-mail: | ywziqi@ziqigy.cn |

| WeChat: | 13735600144 |

| Address: | 浙江省义乌市稠城街道丹溪路159号一楼(自主申报) |

- Zi Qi bronze powder it is a floating flake pigment, copper, zinc and Aluminum Alloy by a certain percentage of the soluble ball, grinding, grading to the required specifications. The main color: red, blue, green and red gold, gold gold and bronze.

Copper gold powder is thicker, the metal sense is stronger, more flicker, brightness is better; conversely, the more thin, metal feeling is weakened, the color is also softer, hiding power is better.

Copper powder in the process of ball milling will be added to the fatty acid, to reduce friction and protect the copper from oxidation, so the surface of copper and gold powder are fatty acid protective layer. High temperature, water, sweat and alkaline media are very easy to damage the surface of the protective layer of copper and gold powder, and then make it slow oxidation, gradually lost the original metal luster.

Note:

Should avoid the use of nitro cellulose and epoxy resin. Because both will react and generate jelly with copper. If it is to be used, it should be used as far as possible in a short time.

Should use low acid value as far as possible (less than 3) of the resin, the resin of the lower acid value system.

Aromatic solvents and helps to make bronze powder particles completely wetting to fully dispersed, should avoid using lipid solvent alcohols and ketones solvent and incomplete acidification.

technical parameters

|

|

Zhegeli |

screenings |

The average particle size of |

special point |

should with |

|

400 |

3500 |

= 1 |

17 |

high luminosity, metal sense of strong, flashing |

fly gold paint, textile printing, screen printing, gold; wallpaper, paint and plastics into |

|

800 |

5200 |

= 0.9 |

59.50 |

metal gloss, strong sense of |

fabric printing, spray paint, plastic paint, |

|

1000 |

7500 |

= 0.8 |

J1\2 |

fine, high brightness |

spray paint, wooden materials, printing ink etc. |

|

1200 |

11000 |

= 0.72 |

3.5 |

high brightness |

printing ink, paint, plastics, printing ink |

|

1500 |

13000 |

= 0.3 |

2.5 |

use of good, high gloss |

canning offset ink |

|

bronze powder |

5200 |

= 0.9 |

59.50 |

metal gloss, strong sense of |

fabric printing, spray paint, plastic paint, |

model

TD; width= < "48|

hue |

number |

size |

mesh |

||

|

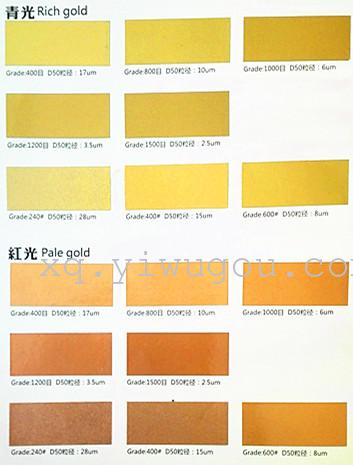

green gold |

QJ-400 |

17 |

400 |

||

|

QJ-800 |

59.50 |

800 |

|||

|

QJ-1000 |

J1\2 |

1000 |

|||

|

QJ-1200 |

3.5 |

1200 |

|||

|

QJ-1500 |

2.5 |

1500 |

|||

|

red gold |

HJ-400 |

17 |

400 |

||

|

HJ-800 |

59.50 |

800 |

|||

|

HJ-1000 |

J1\2 |

1000 |

|||

|

HJ-1200 |

3.5 |

1200 |

|||

|

HJ-1500 |

2.5 |

1500 |

|||

|

green red gold |

QHJ-400 |

17 |

400 |

||

|

QHJ-800 |

59.50 |

800 |

|||

|

QHJ-1000 |

J1\2 |

1000 |

|||

|

QHJ-1200 |

3.5 |

1200 |

|||

|

QHJ-1500 |

2.5 |

1500 |

|||

|

bronze gold |

GTJ-800 |

59.50 |

800 |

||

|

Golden (Qing Guang) |

|

gravure printing gold |

|

52.00 |

900 |

The use of should note: metallic pigment

1, in order to achieve the best results, should be fully dispersed in the metal paint paint system, evenly, not fine. To avoid the dispersion by means of high speed stirring or other strong series processing with high shearing force in the process of dispersion.

Recommendation: pre dispersion method. First select the appropriate solvent or a mixture of several solvents, with the metal pigments in the proportion of 1:1 or 2:1, the solvent into the metal pigment, slow stirring evenly (about 10-20 minutes). In the system to join the base material, the general production of the metal pigment used in advance solvent soak 30 minutes after the line slowly stirring.

2, non leafing aluminium paste can be widely used in polar and non-polar solvents, such as fatty acids or aromatic. Lipids (e.g. butyl acetate), ketones (such as methyl ethyl ketone, methyl isobutyl ketone), alcohols (ethanol). But ( halohydrocarbon chlorinated solvent... ) is not suitable for any aluminum paste.

3, many commonly used binders such as oil varnish base material, acrylic acid resin, alkyd, epoxy ester and water base material, can be applied to non floating aluminiumpasten pigment. But aluminum is a kind of active metal, and the acidity of the paint should be under the control of 7.

4, when the system requires the addition of metal driers, suggested the use of drilling, zirconium, manganese driers.

5, proportion:

Colored primer ratio: 1%-4%

Pure silver primer ratio: 4%-10%

Single metallic paint ratio: 5%-13%

TOP

Items have been added to the Inquiry Basket

There are items in the inquiry basket