X Email Mobile

| 500ml | ¥0.0 | 3819 piece available |

|

| 500ml | ¥0.0 | 3315 piece available |

|

| 500ml | ¥0.0 | 2149 piece available |

|

| 500ml | ¥0.0 | 6277 piece available |

|

| 500ml | ¥0.0 | 1962 piece available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Yiwu Frog Commodity Co., LTD 2yr.

Main Products:vacuum cup,Thermos,Mug

Contacts:Roger XuChat

Mobile:86-18395947007

E-mail: Address:Floor3, Building3,A31 Dongzhou Road, Qingkou Industrial District, Yiwu,Zhejiang, China

Related items

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Super Express [Bao] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

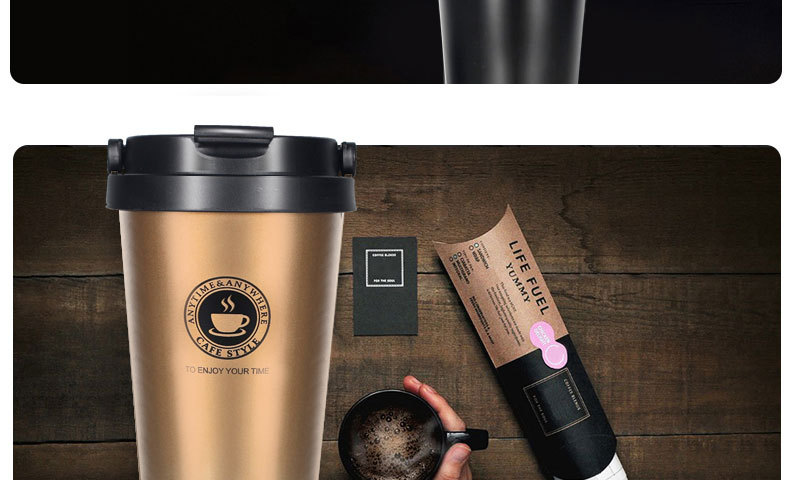

| Product Capacity | 500ml |

| Product Size | 8.5*17.5cm |

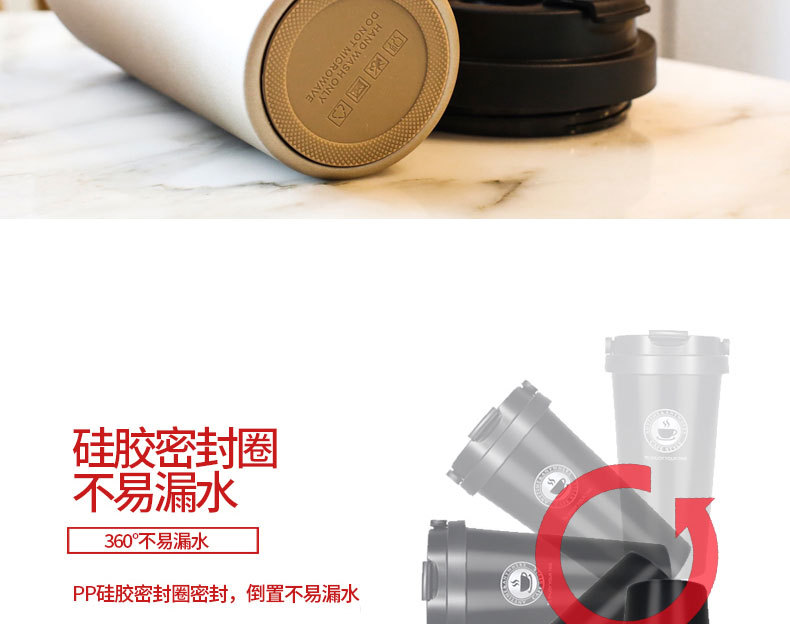

| Product Material | Inner and outer 304 austenitic stainless steel + food-grade PP + food-grade silicone |

| Packing Size/Specification | "79*50*19.5cm/40 pcs per box |

Please do not illegally use images without permission. Any unauthorized use of images by non-agents will be reported.

Custom Cup Related Instructions

*LOGO process: The LOGO on a cup is usually either screen printing or laser engraving.

Laser engraving: Laser engraving is a kind of engraving method that uses high-energy-density lasers to irradiate the workpiece locally, causing the surface material to vaporize or undergo a color-changing chemical reaction, thus leaving a mark. Laser engraving can create various text, symbols, and patterns, with character sizes ranging from millimeters to the micrometer scale, which is of special significance for product anti-counterfeiting. Compared with traditional screen printing, laser processing has no pollution sources and is a clean, non-polluting, high-environmental protection processing technology. Transliterated from the English word "Laser" as laser laser processing. It is a kind of manufacturing process that customers are relatively satisfied with.

Silk screen printing: its full name is "silk screen printing". Silk screen printing is to stretch the silk fabric, synthetic fiber mesh on the mesh frame, using manual carving paint film or photochemistry plate making method to make silk screen printing plate. The silk screen printing technology we are currently using is to use photoconductive materials to make silk screen printing plates through film exposure. When printing, the printed mesh plate is installed on the silk screen printing equipment, and the pressure of the scraping tool back and forth makes the ink uniformly pass through the mesh holes of the text and picture parts to transfer to the bearing printing material, forming the same as the original draft text and picture. Silk screen printing pattern is clear and eye-catching, and the printing process is widely accepted by customers.

*LOGO position: cup body, cup lid, etc.;

1. Select high-quality stainless steel materials and use advanced tail-less brazing bottom technology to refine it.

2. The cup (pot) is divided into an inner liner and a shell, with a vacuum insulation layer in the middle. During the vacuum pumping process, the cup body is subjected to continuous baking at a high temperature of 3000 degrees for more than 5 hours until it reaches a high vacuum state. There are strict QC controls throughout the entire production process. The vacuum performance is subject to three strict checks: a full inspection after vacuum pumping; a full inspection after polishing; and a full inspection before packaging.

3. The production process of vacuum cups (pots) strictly follows the GB/T 2332-97G national standard, which ensures that the vacuum cups (pots) have excellent insulation and cooling retention functions. They also have advantages such as environmental protection, non-bursting, and durability.

4. After numerous meticulous processes, the entire cup (pot) exudes an air of nobility and elegance, with a minimalist and elegant design. It makes a great choice for both home and travel use, as well as a suitable gift!

Knowledge of Insulated Cups

1. Simple Identification Method for Vacuum Insulation Performance: Pour boiling water into the vacuum cup and tightly twist the lid or cover clockwise for 2-3 minutes. Then, touch the outer surface of the cup with your hand.

If the cup body has obvious warm phenomena, it indicates that the product has lost vacuum, and cannot achieve good insulation effect.

2. Seal Performance Identification Method: After adding water to the cup, tighten the bottle cap and cup cover in a clockwise direction, place the cup flat on the table, and there should be no water leakage;

The lid of the cup should be tightly fitted to the cup mouth with no space.

3. Plastic Parts Identification Method: The characteristics of food-grade new plastic are small odor, shiny surface, no burrs, long service life and less prone to aging.

The characteristics of ordinary plastic or recycled plastic are strong odor, dull color, many burrs, and the plastic is prone to aging and easy to break.

4. Capacity Identification Method: The depth of the inner pot is essentially the same as the height of the outer shell (a difference of 16-18MM), which corresponds to the nominal capacity.

Some inferior vacuum flasks may add sand or cement blocks to compensate for the missing weight. Misconception: A heavier cup (pot) does not necessarily mean it is better.

5. Simple Identification Method for Stainless Steel Materials: There are many specifications for stainless steel materials, among which 18/8 indicates that this stainless steel material contains 18% chromium and 8% nickel.

Materials that meet this standard comply with national food-grade standards and are environmentally friendly green products. They are resistant to rust and corrosion. The 304 material is imported steel.

Never rusts; 201 steel produced domestically is also relatively rust-resistant, but its insulation performance after being made into products is not as good as that of 304 steel.

Instruction Manual

1. Before using the new product, it must be boiled with boiling water (or with a little dishwashing detergent) several times to conduct high-temperature disinfection.

2. Before use, please preheat (or precool) for 5-10 minutes with boiling water (or cold water), to enhance the insulation effect.

3. Please do not fill the water to overflowing, to avoid scalding when tightening the cup lid due to the overflow of boiling water.

4. When drinking hot beverages, please do so slowly to avoid scalding.

5. Should not be long-term storage of milk, dairy products and carbonated drinks such as juice.

6. After drinking, please tighten the cup cover to ensure hygiene and cleanliness.

7. Cleaning should be done with soft cloths and a diluted food-grade cleaner in warm water. Do not use alkaline bleach, metal scouring pads, or chemical rags.

8. The inner side of stainless steel cups sometimes develops some red rust spots due to the influence of iron and other substances in the contents.

Soak in warm water mixed with diluted vinegar for 30 minutes, then thoroughly clean.

9. To prevent the production of odors or stains, and to maintain long-term cleanliness. After use, please clean it thoroughly to ensure complete drying.

Update time:

TOP