Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Pujiang Jiafeng Magnet Steel Factory 15yr.

Contacts:Zhao Jianfeng Chat

Mobile:86-13515790888

E-mail:zjjfcy@126.com

Mob: +86 13626895166 / +86 13626893268

QQ:240161369

Tel: +0086-0579-85185263

Fax: +0086-0579-85199547

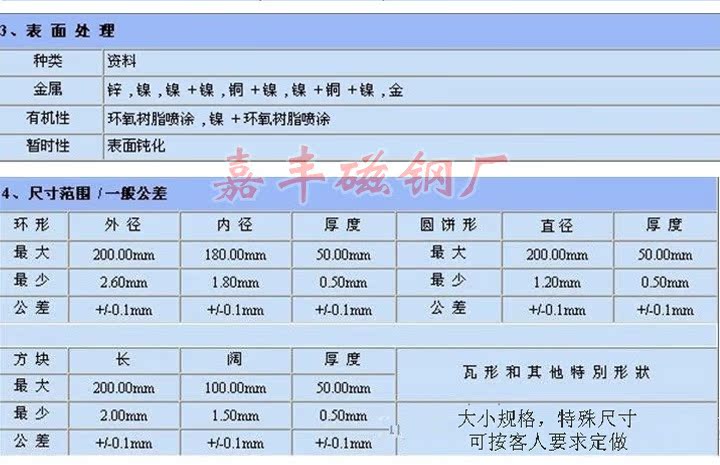

Ndfeb magnets: ndfeb is currently found to be the most commercially available magnet, known as the magnetite king, which has a very high magnetic energy with a maximum magnetic energy product (BHmax) more than 10 times higher than Ferrite. Therefore, also known as: strong magnetic, such as magnetic steel. Its own mechanical processing performance is also quite good. The working temperature can reach up to 200 degrees Celsius. And its quality is hard, performance is stable, have very good cost performance, therefore its application is extremely wide. But because of its strong chemical activity, its surface must be treated.

Ndfeb permanent magnet is based on intermetallic compound Nd2Fe14B. Relative to the cast al-ni-co permanent magnet and ferrite permanent magnet, ndfeb has extremely high magnetic energy accumulation and coercivity, and can absorb mass equal to 640 times its own weight. Due to the advantages of high energy density, nd-fe-b permanent magnet materials have been widely used in modern industry and electronic technology, which makes it possible to miniaturize, lightweight and thin equipment such as instruments, electroacoustic motors and magnetic separation magnetization. Material characteristics of nd-fe-b are the advantages of high ratio of performance, good mechanical characteristics, easy to cut processing; The disadvantage is that the Curie temperature is low, the temperature characteristics are poor, and the powder corrosion is easy to be made, and it must be improved by adjusting its chemical composition and adopting surface treatment method to meet the requirements of practical application.

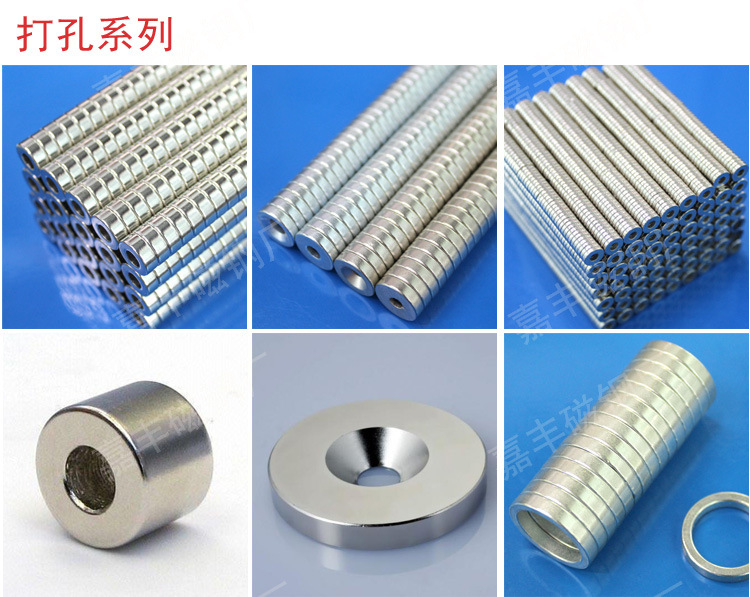

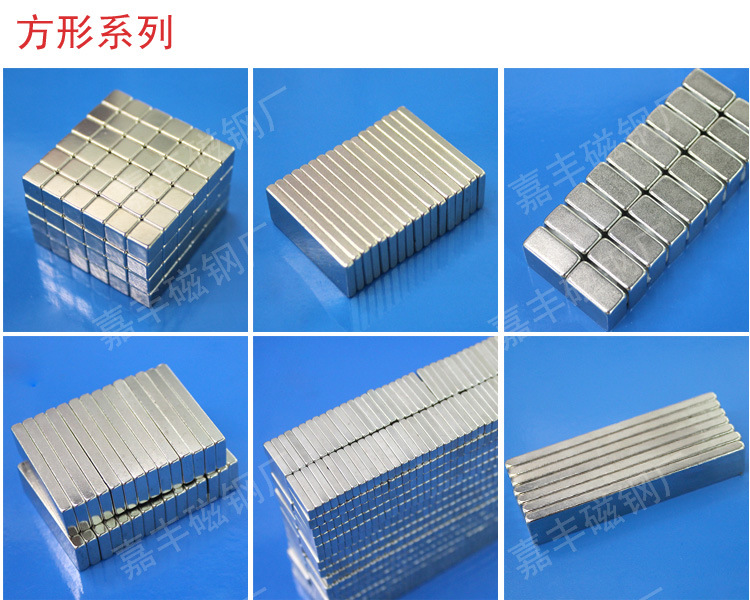

Manufacture process of ndfeb powder metallurgy process, will contain a certain proportion of raw materials such as: dysprosium, neodymium, iron, cobalt, niobium, praseodymium, such as aluminum, copper, boron iron by medium frequency induction melting furnace smelting alloy ingot, and then broken into 3 ~ 5 microns powder, and forming technology in the field, after forming the green in the vacuum sintering furnace sintering density and tempering time, thus obtained a certain magnetism of permanent magnet blank. After grinding, drilling and slicing, the finished product is obtained by surface treatment.

Update time:

TOP