Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

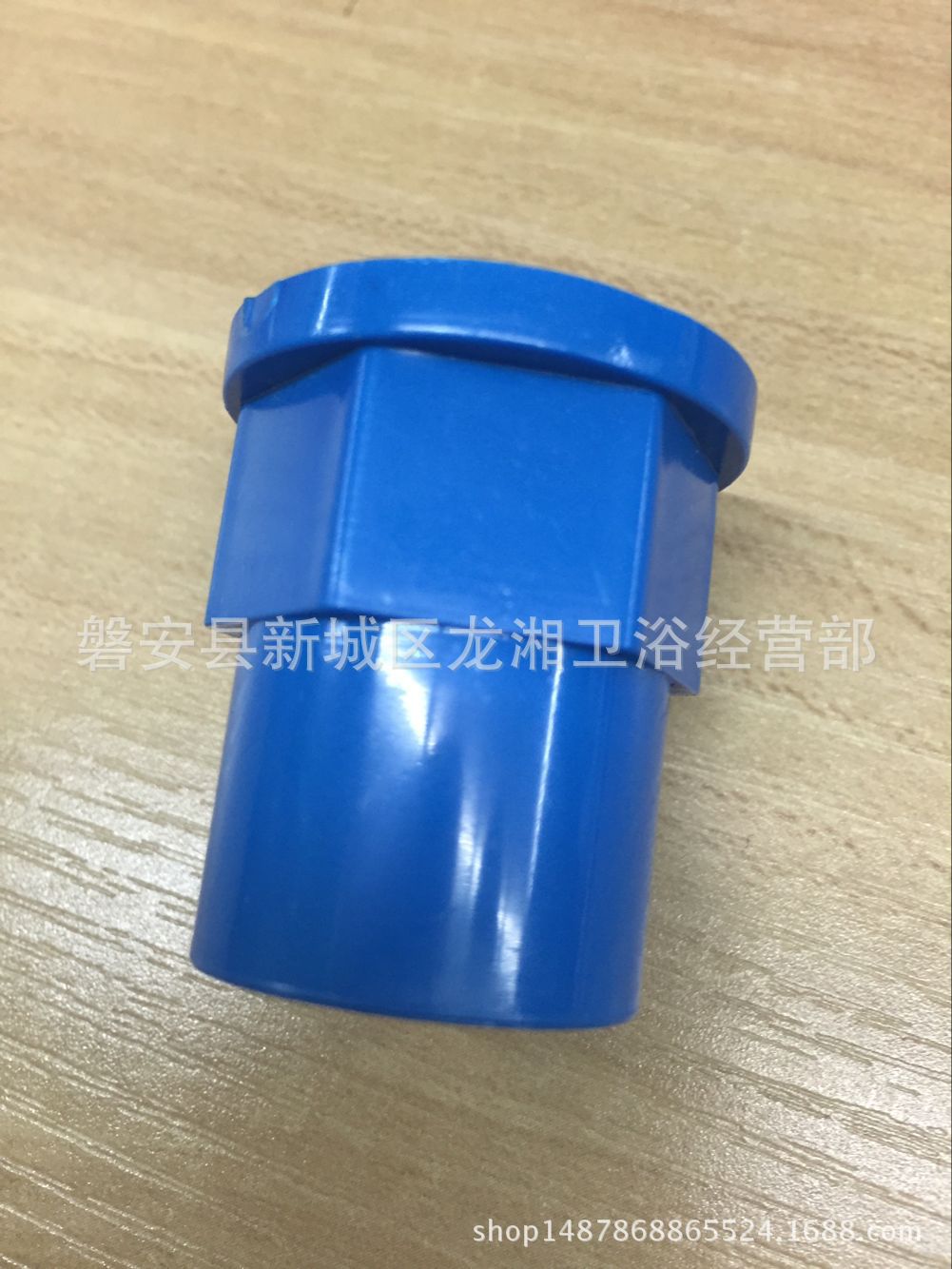

X Email Mobile

Long Xiang sanitary ware company specializing in the production of PVC pipe, drain pipe. Feed pipe. Valve. Ball valve. Accessories and other products of professional production and processing company, the company product design is novel, diverse styles, beautiful and easy, water effect is good, the price is reasonable, quality is reliable, quality first, customer first, lead the innovation, enterprise spirit of never stop. Has a complete and scientific quality management system, strictly enforce the ISO9001 quality management system. Long Xiang sanitary ware co., LTD. Has been in good faith, the strength. Product quality for the purpose of gain recognition in the industry. Friends from all walks of life are welcome to visit, guide and negotiate business. Company store address: yiwu international trade city second district, fourth floor, contact number, 18905899696.![5JZ}RQH]S6G}G$2V452`RBF_看图王](https://cbu01.alicdn.com/img/ibank/2017/981/506/4000605189_394221024.jpg)

![9LM]NYTHXCQNLBN@E)54[`7_看图王](https://cbu01.alicdn.com/img/ibank/2017/145/394/3997493541_394221024.jpg)

Part function of extruder in PVC water supply pipe fitting - PVC casing production line

Functions of the extruder in PVC casing production line: it is equipped with quantitative feeding device to match the extrusion volume and the feeding volume, so as to ensure the stable extrusion of products. Due to the characteristics of conical screw, the feeding section has a large diameter, and it has a large heat transfer area and shear speed of the material, which is conducive to the plasticization of the material and the screw of the measuring section

The small diameter reduces the heat transfer area and shear rate of the melt, so that the melt can be extruded at a lower temperature. When the screw rotates in the cylinder, the PVC mixture is plasticized and pushed to the head of the machine, so as to achieve compaction, melting and mixing homogenization. And achieve the purpose of exhaust, dehydration. Feeding device and screw drive device

Variable frequency speed control, can achieve synchronous speed control. Turn rack material movement by cylinder by pneumatic control, is expected to set up there is a limit device, when cutting saws cutting pipes, pipe to transport, after a delay, cylinder into the work, to achieve double material movement, the purpose of discharging. After discharging, it will be automatically delayed for several seconds

Reset and wait for the next cycle.

How are PVC water supply pipe fittings made

PVC pipe in the decoration, the application of very much. But what do you know about the production process of PVC pipes? The general PVC pipe should be mixed during production. Extrusion process; Finalizing process; Traction process.

The process of each process is described in detail below.

High-speed mixing, mixing process of PVC pipe in additives into the gap of PVC resin, the fertilizer evenly dispersed in the resin, considering the temperature above 1000 c for steam steamed out of a material, so the temperature of the hot mix machine in commonly 100 ~ 1200 c. To allow the agent to fully contact with the PVC particles, reduce the filling

The adsorption action of the charging agent on the auxiliary agent should start the heat mixer immediately after adding PVC resin, and then feed it in the following order: stabilizer, various processing AIDS, color material and filler. In actual production, most of the raw and auxiliary materials are put into before starting the hot mixer. Let me do that. The first part is finished.

Extrusion molding process. The cylinder temperature of solid conveying zone is generally controlled at 100~1400C. If the feeding temperature is too low, the solid conveying zone will be extended, and the length of the plasticizing zone and the melt conveying zone will be reduced, which will lead to poor plasticizing and affect the product quality. In the third. A tube extruded from a die at the head of a machine

It has to be cooled, hardened and shaped. Finalize the design with fixed diameter sleeve to finalize the outer diameter and the inner diameter finalize two ways commonly. The structure of external diameter is simple and easy to operate, which is widely used in China.

Traction process. The purpose of the traction device is to provide a certain amount of traction and traction speed for the pipe extruded by the machine head, to evenly draw the pipe, and to adjust the wall thickness of the pipe by adjusting the traction speed. The traction speed depends on the extrusion speed. Generally, the traction speed is 1%~3% faster than the extrusion speed.

The common PVC pipe can only be produced through the process of these steps.

Installation instructions for connection of PVC water supply pipe fittings

Pipe connection installation is tee is (cross) in the riser and horizontal tube joint, joint formation caused by water flow tongue, horizontal pipe flow, drainage system pressure fluctuations, sanitary ware water seal is easy to be destroyed, toxic or harmful gases into indoor drainage pipe, cause environmental pollution. The right to do

Method is should be installed in this 45 ° inclined tee or at the tee. 2, water drainage riser and drainage pipe connect fitting the homes of connection in some tall buildings, designers often need to leave home in the design of pipe diameter amplifying a number, and the construction is often at the bottom of the riser with two the same as the riser pipe diameter 45 ° elbow connection, again

When the diameter is changed on the discharge pipe, it is easy to form the air plug at the connection diameter change point, causing the pipe blockage and affecting the drainage of the pipe. The correct method is to enlarge the elbow with the reducer tube at the bottom of the riser, and to enlarge the elbow with the eccentric reducer tube, and the eccentric reducer tube with the eccentric eccentricity side in the turn

On one side of the circle.

Part function of extruder in PVC water supply pipe fitting - PVC casing production line

Functions of the extruder in PVC casing production line: it is equipped with quantitative feeding device to match the extrusion volume and the feeding volume, so as to ensure the stable extrusion of products. Due to the characteristics of conical screw, the feeding section has a large diameter, and it has a large heat transfer area and shear speed of the material, which is conducive to the plasticization of the material and the screw of the measuring section

The small diameter reduces the heat transfer area and shear rate of the melt, so that the melt can be extruded at a lower temperature. When the screw rotates in the cylinder, the PVC mixture is plasticized and pushed to the head of the machine, so as to achieve compaction, melting and mixing homogenization. And achieve the purpose of exhaust, dehydration. Feeding device and screw drive device

Variable frequency speed control, can achieve synchronous speed control. Turn rack material movement by cylinder by pneumatic control, is expected to set up there is a limit device, when cutting saws cutting pipes, pipe to transport, after a delay, cylinder into the work, to achieve double material movement, the purpose of discharging. After discharging, it will be automatically delayed for several seconds

Reset and wait for the next cycle.

Jiangshan feiya plastic factory located in western zhejiang is a set design, production, marketing and service as one of the pipes, pipe fittings enterprises, Mainly produces PVC water supply pipe fittings pipe, drainage pipe, line pipe and accessories. The Company introduced the latest technology and advanced production line, the detection means perfect, Strong technical force, scientific management methods. Companies rely on solid technical strength and rich practical experience. The close relation between industry and enthusiasm to provide convenient service for the general customers, And undertake the development of new products our customers tasks and technical advisory work.

The company since its inception products have been exported to all over The country, strong technical force, complete testing equipment, adhere to modern management mode, We're learning new products with high quality.

The main purpose of PVC electrical fittings fittings fittings:

PVC electrical fittings from the excellent performance of strongstress - resistant, corrosion - resistant, anti - moth, flame retardant, insulation and so on. In the area of construction, It also has the advantage of light weight, easy to cut, easy to bend, installation flexibility, quick construction and so on. The retardant Pvc electrical casing has extensive use in concrete, Floor or between walls as electrical conduit, underground pipe can also be used as general wiring conduit pipe Ming and telecommunications, network cabling pipe. PVC electrical accessories, Electrical conduit has good bending performance. PVC electrical conduit is a kind of PVC as the main raw material, add some special resist, by extrusion of a pipe, Commonly known as PVC electrical conduit retardant wire and pipe, Tube and rodents. Retardant electrical casing production process is now usually carried out in strict accordance with JG3050-1998 production. Retardant electrical casing from the models of Φ 16 ~ Φ 63 mm, Specifications are 205 (light), 305 (medium), 405 (heavy).

Retardant electrical casing has a variety of performance characteristics, as an electrical conduit, its insulation performance is very good, with good anti - current breakdown voltage capability, Generally able to withstand 25 kV voltage without breakdown, and it is no live dangerous. Retardant electrical casing also has a very good impact to hold, it can withstand the pressure, Can be concealed within the concrete, no fear of the damage of pressure and shocks. The Retardant electrical conduit also has good fireproof performance, because of high oxygen index, It is hard to make flame. If leave the flame, it will instantly self - extinguishing. Retardant electrical casing also has some moisture, acid corrosion properties, And will not cause corrosion when together with other materials.

Retardant electrical casing has a smell which pest does not like, thus avoiding the problem of pest damage bite. It has good flexible performance, with good bending to hold, We only need to insert a spring in a fire - retardant electrical casing, without heating, It can be blended with hand. Now the fire - retardant electrical conduit can be 2 in the building or underground electrical installation, and its use is in the extension.

PVC electrical accessories - Conduit Profile

Pvc electrical accessories is the abbreviation ofpolyvinylchloride, polyvinylchlorideproducts include common pipes, soles, toys, doors, Stationery, polyvinylchloridepipe is an common products ofpolyvinylchloride. Althoughpolyvinylchloridehas the features of stable, hard to be the acid corrosion, high heat tolerant, Its development are hindered by cost barriers, industrial policy barriers, scale barriers, financial barriers.

Vinyl chloride (PYC) resin as the main raw material, wire, pipe products, because of its role in the fire resistant, polyvinylchlorideis widely, informs in wire and fiber. The braking, informs the to make gloves.

Polyvinylchloridecan be made from ethylene and chlorine and the catalyst.

PVC electrical conduit fittings are cheap, Widely, informs. Polyvinyl chloride resin is white or pale yellow powder. The company's additives can be added \"according to company's use, Polyvinylchloridecan present company's physical and mechanical Properties. A variety of hard, soft and transparent products can be made if adding an appropriate amount of plastic ticizer in PVC resin.

Convenience of PVC accessories in construction

PVC electrical accessories are very light, usually 1/10 of pressure tube, 1/6 of steel, Convenient for transportation and installation. PVC pipe construction is very convenient. Conduit consists of connectors, waterproof operators, brackets and other components. Easy construction, no need to pour concrete protective layer. Stent modular connection, easy to install, and can greatly shorten the construction period, non-radioactive substances, Has significant economic and social benefits.

Good corrosion to hold is a large characteristic of PVC casing, PVC casing material has excellent power, acid, alkali, salt and other chemical solvents, corrosion, no case of oil cracking, Can adapt to various soil and the work environment. High strength, heat to hold, long service life. Compared to traditional forms of asbestos and cement, it with a flexible, High temperature, Easy to break and aging, long life, non - radioactive contamination and other characteristics, its strength can replace steel, and overcome corrosion and get the damage under caused by It is high temperature of single-core cable.

Informs the as an electric pipe, of course, good insulating properties is indispensable. The PVC casing itself retardant power, put out away from the fire, high volume resistivity, Power, excellent insulation properties. The main ingredient of PVC casing ispolyvinylchloride, while adding other ingredients to enhance its heat to hold, toughness, Ductility. This table top layer is made, the main ingredient in the middle ispolyvinylchloride, the lower is the adhesive - anyway: spreads over gse-backed loans. It is now loved by the world, And is quite popular and is also widely used as a synthetic material.

Maintenance treatment of PVC electrical wire and pipe fittings

Pvc conduit fittings are diverse, and we can choose according to the actual situation.

Due to external force causes small area damage, cracks of Pvc electrical conduit fittings, and if in the same physical properties, adhesion treatment is available. Cut the same diameter of the pipe, covering an area larger than the on parts to clean and roughen the inside of a selected pipe, apply adhesive chip on on parts of the and of the selected pipe, Cover the repairing tube sheet to the damaged area, and fasten with a pipe clamp or wire. Pvc conduit can also use welding repair method, but be aware that welding parts is dry. Meanwhile the remove dust, oil and other oils on its surface, the adhesive must be cleaned before welding.

When the need to replace on pipe, this damage part should be amputated, replace the new pipe, specification over Φ 160 can be use on - site hot socket repair method: Lift up both ends of the pipeline which is sawed off, both sides make chamfered. The length of replacement tube should be segment length plus insertion length on both ends, Heat the replaced pipe on both ends,then insert into the original pipe, and put it into the ditch, then water can go through after cooling.

Flange quick, amputate PVC pipes where need to be replaced break both ends, take four plate bearing joints, substitute tube section, the four bearing plate joints are set into ends, Flange joint of the four ends. Quick Plastic coupling connection, saw expansion or damaged parts, set into a loose flange and a rubber ring at both ends. Set into flanged proximity, pushed back flanged tangto an equal distance from both ends of the broken pipe, fasten the loose flange and flange with bolt.

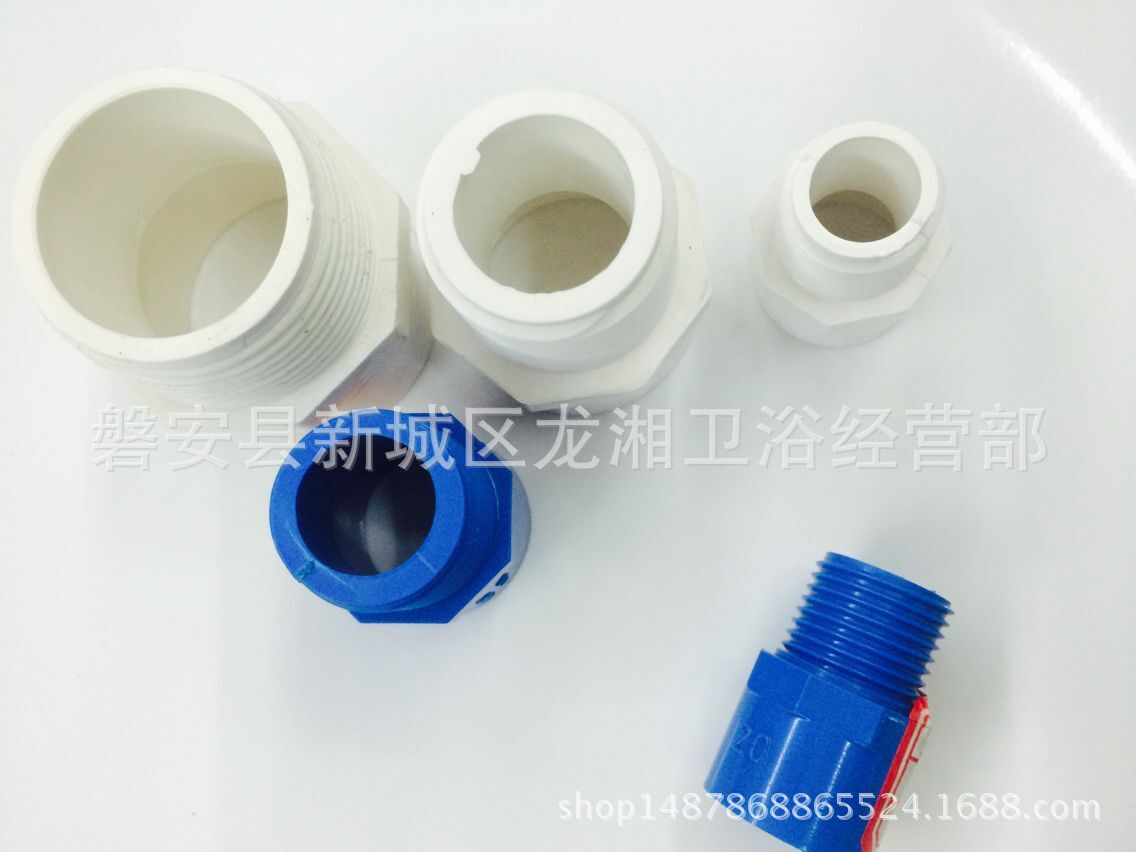

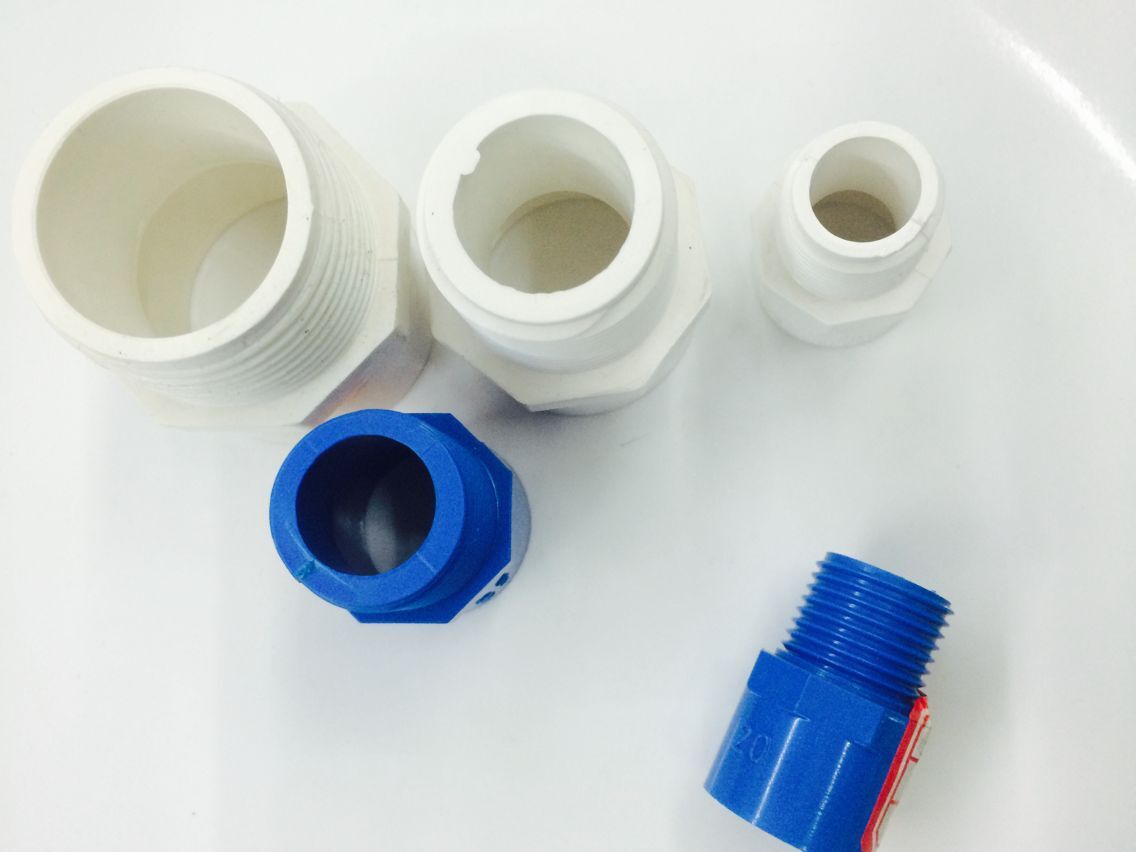

Warm prompt: because of our product size too much, did not offer, packing minimum quantity according to the product will be floating, 10 cases packing products to the minimum please want want before you place the order or to inquire, thank you for your cooperation!

| The size | PCS/CTN | Weight (g) | Carton Size (cm) |

| 1/2\" | 600 | 28 | 50 x30x26 |

| 3/4\" | 350 | 44 | 50 x30x26 |

| 1\" | 200 | 73 | 50 x30x26 |

| 1 1/2\" | 80 | 148 | 50 x30x26 |

| 2. \"\" | 48 | 271 | 50 x30x26 |

Update time:

TOP