Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

SAILHOPE HARDWARE TOOLS 15yr.

Contacts:Lu Minghui Chat

Mobile:86-13819957205

E-mail:waycsu880603@163.com

A brief introduction of :

A special tool for unloading 1, tighten or loose screw. It has a plurality of inner six edge type sleeve and one or a plurality of handle of the sleeve, the inner six edge of the sleeve is arranged according to the type of the bolt, and can be selected according to the requirement. A water supply pipe connecting parts, can be used for steel and cast iron pipe connection

2, reinforced connection sleeve, for mechanical connection of reinforcement of a special product, divided into cold extrusion sleeve, the taper thread sleeve and straight thread sleeve.

All of the following sleeve, the same specifications six cents and twelve cents.

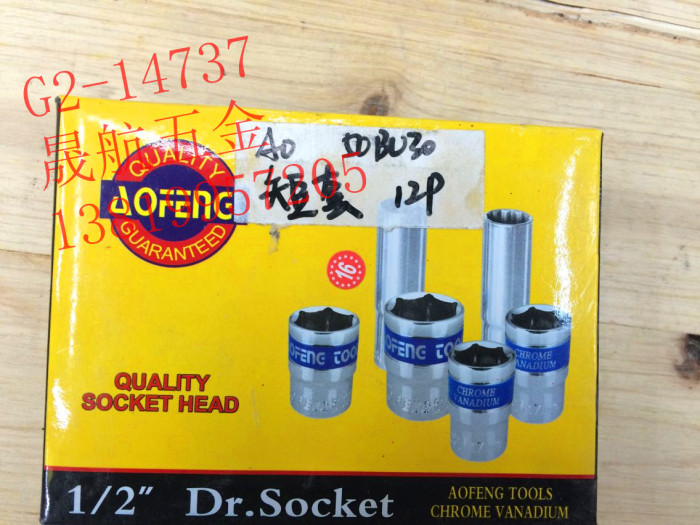

high-grade chrome vanadium steel bright blue hexagonal and 12 angle 1 / 2 head metric lengthened sleeve price and packing quantity is as follows:

high-grade chrome vanadium steel bright blue hexagonal and 12 angle 1 / 4 head metric lengthened sleeve price and packing quantity as follows:

high-grade chrome vanadium steel bright blue hexagonal, twelve angle 1 / 4 head metric short sleeve price and packing quantity is as follows:

two: product features

1. using international 45 steel, special manufacturing process, high dimensional accuracy, reliable quality.

HRB335 grade and HRB400 grade ribbed steel bars can be connected with 16- 2. with 40mm.

3. inspection by the national construction quality supervision and inspection center, to achieve the I level of JGJ107-2003 joint standard.

That the 4. standard positive and negative thread type, different diameter of the three series 52 varieties, can satisfy building structure in horizontal, vertical, inclined to other parts of the same diameter, different size and adjust the length and direction of the steel bar connection demand.

three: technical features: sleeve

1, suitable for the construction of the steel bar in the cold extrusion connection technology structure of the steel reinforced concrete structure of the various kinds of structures under tension and compression.

2, material saving, energy saving, not by the composition and types of steel bars.

3, can be fully connected.

4, can be prefabricated in advance, factory work, not occupation period, all-weather construction.

5, the operation is convenient and fast, fast construction speed, can greatly shorten the construction period

reinforced connection strength characteristics of joint sleeve technology to the industry standard JGJ107-96 in a joint performance requirements. The thread tooth shape is good, the precision is high, the connection quality is stable and reliable. A wide range of applications, suitable for diameter 16-40mm. In the same direction and position of the second and third grade steel bars in any direction and position. Adjustable type: positive and negative screw type sleeve is suitable for connecting turn iron reinforcing cage can not rotate at the bar. Construction speed: thread processing ahead of the prefabricated and on-site processing, assembly and construction. Energy conservation, no pollution, construction safety and reliability.

four: Classification: socket wrench

(1) according to the size to the size of the four square): 1 / 4 ", 3 / 8", 1 / 2 "three kinds of specifications," is inch, 1 "is equal to 25.4MM

(2) according to the length: long sleeve, short sleeve, sleeve shaped E

(3) according to the edge: 6 corners, 12 corners of

(4) appearance: single channel and double channel; knurling; cylinder; nickel and etc.

(5) use: manual and pneumatic wrench socket wrench (black chromium molybdenum) of

Five:

(1) surface treatment: bright chrome like mirror, very bright

(2): Matt chromite

(3) electrophoresis: black, brightness. separation is under external DC power supply, the charged particles in dispersion medium to the cathode or anode do directional movement, drive material;

(4): black phosphating, no luster. The sleeve is immersed in the phosphating solution, which is deposited on the surface to form a layer of insoluble crystalline phosphorus, which is the conversion process of phosphate.

Six the production process

blank (there are a variety of specifications) - Polish (removal of burr thorn, etc.) - turning (mainly forming) - Polish surface engraving (such as knurling, printed logo) - heat treatment (in order to increase the hardness) plating (nickel or chromium, etc)

seven: distinguish between good and bad

(1) look at the surface: is there a flash, specifications are in line with the standard size, there is no scratch

(2) er: with special tool measuring torque and hardness; size measurement; salt mist test note: when the socket wrenches hexagon or twelve angle size on the side is less than or equal to 32mm, the hardness value of not less than HRC39 than 32mm and hardness of not less than HRC35.

sleeve small knowledge

According to the use of driving device classification:

1, pneumatic sleeve (or pneumatic sleeve)

2 manual, sleeve

3, electric socket: electric wrench as the driving force of the sleeve.

According to the material classification

Chromium (CR), molybdenum (MO) and iron (FE) and carbon (c) of the alloy

1, chrome molybdenum steel (Chrome-Molybdenum steel, good performance of high temperature processing, after processing is beautiful, can quench depth and shock absorption performance is good, so in the industry is often used to manufacture of pneumatic tools and large hand tools.

2, chrome vanadium steel (Chrome-Vanadium steel, chrome vanadium steel is added chromium vanadium alloy elements of alloy tool steel, mainly used in manual tools.

3, 45# carbon steel, that is, 45 steel, about 0.45% of the amount of carbon, due to the good processing performance and processing technology and more commonly used in steel processing materials. Above material Cr-Mo (Ge Mugang) the best material is the best material sleeve.

Update time:

TOP