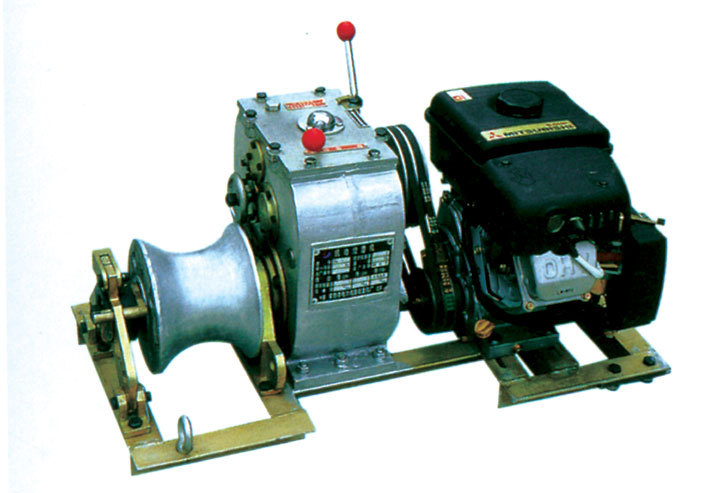

It is widely used in electric power, post and telecommunication line construction to set up poles and towers, power transmission line and tightenline, and also can be hoisted and towed in buildings, docks and other places. It has been proved by experiment and field practice that it has the advantages of reasonable structure, small volume, light weight, large utility, flexible operation and convenient transportation, and is well received by power and telecom operators.

The motor grinder model has been rearranged in the new execution standard of the state power department. The following entry will be defined according to the new model.

Instructions for use of motor grinder for JJ type

I. product model: belt driven 1T 3T 5T 8T

Ii. Product name: motor grinding

Use: motor winch has been proved by experiment and field practice, with the advantages of combining principle, small volume, light weight, great power, flexible operation and convenient transportation, which has been well received by power operators.

Iv. Specifications:

Output forward: the slowest linear speed is 9 revolutions/min; Maximum speed 50 RPM.

Output reversal: 4.7 revolutions/min 40 revolutions/min

1T (length x width x height) (mm) 800*380*480 (admission)

800*360*440 (electric)

3T external dimensions (length X width X height) (mm) 840X450X500 (admission)

780*450*500 (domestic steam)

840*600*500 (domestic wood)

770*600*460 (electric)

Weight: 82/85/108/108 kg

5T external dimensions (length X width X height) (mm) 1000*550*520 (admission)

1000*550*520 (domestic steam)

1000*750*600 (domestic wood)

1000*850*520 (electric)

Weight: 135/135/168/160 kg

8T overall dimensions (length * width * height) (mm)

1050*550*550 (domestic petrol engines)

1050*750*630 (diesel engine)

Structure and working principle

1. Power:

Imported petrol engine power: 4 HP

Power of 1T motor: 2.2 kw

Imported petrol engine power: 6 HP

3T gasoline engine power: 6 HP

3T diesel power: 4 horsepower speed: 2600 RPM

Power of 3T motor: 3 kw

Imported petrol engine power: 9 HP

Power of 5T domestic gasoline engine: 9 HP

5T water-cooled diesel power: 6.6 horsepower RPM: 2600 RPM

Imported gasoline engine power: 13 HP

Power of 8T domestic gasoline engine: 13 HP

8T diesel engine power: 10.5 HP

2. Transmission mode and transmission:

Power and transmission gearbox 3T A two triangular belts, 5T two B triangular belts, and equipped with transmission clutch. The input gear box has a counterclockwise speed of 1100 RPM. By changing the speed of the gearbox, output the following speeds respectively:

Positive 13 revolutions per minute 23 revolutions per minute

Reverse 12 revs/min 20 revs/min

3. Braking

There are two kinds of brake devices: automatic clamping brake and clutch driving interlock brake.

4. Hand device:

During the operation of the grinder, if the prime motor fails, the sling can be moved with the hand device, and the sling can be continued to be lifted or put back to the ground.

5. Lubrication method:

The transmission gear box is made of oil seepage and the outer bearing is made of butter.

Vi. Operation method:

1. Before starting up the machine, the drive clutch of the grinder must be opened and the front and rear shifters must be moved to the neutral position before starting up.

2. When you move the clutch, the action should be quick, otherwise the interlock brake will not work, which will increase the impact force of automatic brake pawl. Should not be too hard when starting up, until the belt pulley can drive the input shaft rotation not to slip.

3. The transmission clutch must be opened when changing gears; otherwise, the gears will be damaged. After changing gears, check whether the changing gears are fastened to prevent jumping.

4. In the process of shifting gear, if there is difficulty in entering gear, you cannot force into gear, you can use it

Hand device: use a wrench to turn the hand device to an Angle to enter the gear.

5. Wire rope installation method:

(1) open the drum clutch, put the wire rope head on the drum to tighten, and then close the clutch.

(2) disassemble the bearing support movable seat on the outer side of the reel and wind the wire rope into the reel to tighten.

(3) wire rope winding: run from the bottom to the top, that is, the feed rope is lower, facing the reel, wind counterclockwise, the feed rope is against the prime mover end, and wind 5-6 rolls.

(type 5T is wound around 8 rolls) the brake does not work if the brake is wound backwards.

Vii. Maintenance and safe use of the grinder

In order to maintain the normal operation of the grinder and extend its service life, the maintenance and maintenance of the grinder must be strengthened. The operator must know the structure and performance of the whole machine and master the operation method.

1. The allowable load on the reel is 3T: 3000 kg at slow turn and 1800 kg at fast turn; 5T slow turn 5000 kg, fast turn 2500 kg, do not overload operation.

2. A quarter of the lubricating oil must be maintained in the transmission gear box.

3. In order to prevent the phenomenon of shifting gear, spring steel ball is installed in the shift fork for the purpose of changing gear positioning. Therefore, in use, it is important to check whether the spring ball is fastened. If not, the spring must be replaced before use.

4. For the automatic brake and interlock brake, the wearing condition of the bakelite shall be checked frequently. The rotation and return clearance of the automatic brake gear shall be 0.5mm.

5. The automatic brake device is in the gearbox of variable speed. When lifting, the automatic brake gear makes a \"dub, dub and dub\" sound, which proves that the speed-tooth works normally.

6. Anchoring method of machine base: the bearing support on both sides of the drum (with two holes) shall be the anchor point, and other positions shall not be used as the anchor point.

7. The locking pin of the drum bearing seat must be matched with the corresponding hole. It is forbidden to use other screws to replace the locking screw.

8. The casing of the transmission gear box is made of aluminum alloy. The screws on it should not be too tight and unnecessary to be disassembled and assembled.

9. After the machine is transported over a long distance, detailed inspection must be carried out to check whether the fastening screws of all parts are loose and whether the lubricating oil is normal.

10. The prime mover is gasoline and diesel engine, which can be carried out according to the operation requirements of the machine.

11. Before using the machine, check whether there is any debris on the machine body and whether there are any obstacles affecting the normal operation of the machine around.

At the same time should check the transmission mechanism, all normal before use.

12. After each use of the machine, the dust, oil and other dirt on the machine shall be cleaned in time. All cleaning work shall be carried out after the machine stops running.