Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

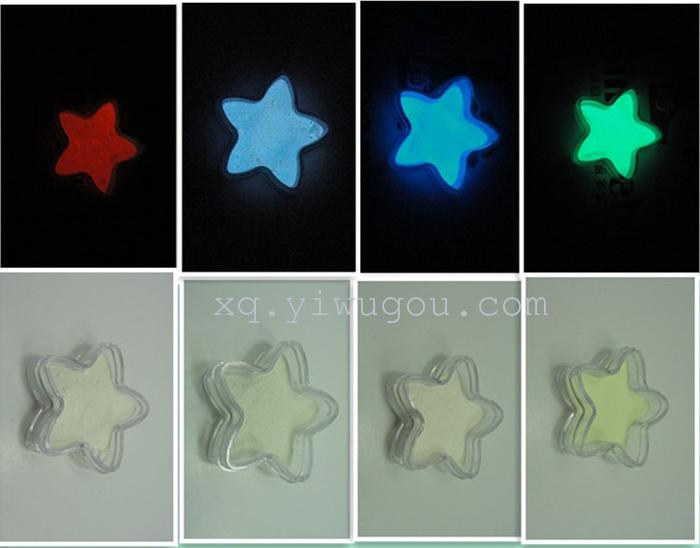

| Technical indicators and instructions of Ziyan luminous powder | ||||||||

| Model | The light-emitting brightness(mcd/m2) | The average particle size | The light-emitting | The light-emitting | Appearance | |||

| AFTERGLOW INTENSITY | AVG.PARTICLE SIZE | Time | Color | Color | ||||

| 1min | 2min | 10min | 60 min | Um | HR | In the dark | Daylight | |

| Y1150 | 3600 | 2120 | 590 | 90 | 40-60 | 14 | Yellow-green | Yellow-green |

| Y880 | 2950 | 1890 | 430 | 78 | 80-100 | 14 | Yellow-green | Yellow-green |

| Y408 | 760 | 436 | 108 | 16 | 8-12 | 12 | Yellow-green | Yellow-green |

| Y550B | 980 | 560 | 230 | 40 | 60-75 | 12 | Yellow-green | Yellow-green |

| Y625 | 1310 | 710 | 150 | 38 | 25-35 | 10 | Yellow-green | Yellow-green |

| Y450 | 1700 | 1120 | 290 | 40 | 45-55 | 12 | Blue-Green | Yellow-green |

| YG250 | 60 | 38 | 7.8 | 1.2 | 40-60 | 2 | Purple | White |

| Y350 | 380 | 208 | 63 | 15 | 40-60 | 6 | Sky Blue | light yellowish green |

| YH220 | 275 | 142 | 22 | 10-20 | 0.5 | Orange-red | White | |

| YHG220 | 121 | 71 | 11 | 10-20 | 0.5 | Red | Orange | |

| YBG320 | 360 | 202 | 58 | 12 | 20-30 | 5 | White | White |

| Zinc sulfide | 330 | 165 | 24 | 2.2 | 10-25 | 3 | Yellow-green | Yellow-green |

| Y650W | 1630 | 980 | 308 | 37 | 30-45 | 12 | Yellow-green | Showboating in a raucous mix |

| Y625W | 1368 | 827 | 265 | 28 | 25-40 | 12 | Yellow-green | Chinese people |

| Y980W | 2210 | 1150 | 534 | 58 | 45-65 | 14 | Yellow-green | Yellow |

| Note: Y650W,Y625W,Y980W it is water-based luminous powder, suitable for water-based paint, paint, etc. | ||||||||

|

Loading and storage: |

|

Luminous Powder is suitable for storing in a dry place to avoid contact with moisture, and nylon bags are sealed for storage; |

|

Products are usually packed in double-layer transparent bags or independent vacuum bags.. I. Taboo of use: |

|

25 kg/ bucket |

|

1. Avoid using in acidic environment (neutralization reaction between al203 and acid). |

|

2. Avoid contact with water (it will absorb moisture in the air, and use luminous powder to turn black without glowing and caking). 3. Avoid contact with metal (it will affect the unsaturated state of light storage powder and affect light emission). 4. Avoid high temperature and high speed friction (it will change the existing structure of luminous powder). 2. Usage: |

|

1. Injection Molding: first weigh the luminous material proportionally, add a proper amount of paraffin oil (which can spread oil), adjust it into paste, and then pour it into the Weighed The glue can be produced after being fully stirred and evenly mixed. Materials that can be injection molded include PP,PE,PVC,PU,PS,ABS,TPR,EVA, PMMA, nylon, etc. The more transparent the plastic material is, the better the luminous effect is. Use fluorescent Toner as much as possible. The less you add, the better, |

|

2. Mixing ink: weigh the light storage powder, transparent varnish, and relevant additives to fully stir evenly. |

|

III. Usage ratio: |

|

1. Injection Molding: 4-10% is recommended, 5-6% is often used, and it is adjusted according to customer requirements. More than 8% with coarse powder brightness is good, low concentration ratio with fine powder Good brightness. 2. Ink mixing: 40-60% is recommended, and 50% is commonly used. |

|

IV. Precautions: |

|

1. Mixed with neutral or weak reducing transparent resin, the recommended proportion is 40-60%, and the commonly used proportion is 50%. The higher the proportion, the brighter the light will be. 2. Use glass, ceramic or plastic containers to store, stir and disperse metal objects. |

|

3, luminous material has a large proportion and is easy to precipitate. High viscosity resin or anti-setting agent should be used. Stir well before use. Thinner can be used to adjust the viscosity, but heavy metal compounds cannot be used as additives. |

|

4. The printing background color is mainly white and reflective, which can improve the brightness and luminous time. If the fluorescent color is added, try to be less than 1% of the luminous powder, fluorescent The less pigment, the smaller the influence on brightness. |

|

5. To achieve good luminous effect, try not to choose luminous powder with too fine particle size. The smaller the luminous powder particle size, the weaker the luminous brightness. Printing or |

The coating thickness is better than 130um (80 mesh printed twice)

Update time:

TOP