Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Dingzhou Xinhua Metal Net Co. Ltd. 15yr.

Contacts:Liu Guanyu Chat

Mobile:86-15257951881

E-mail:lgy5202010@163.com

1. The material of electric welding mesh

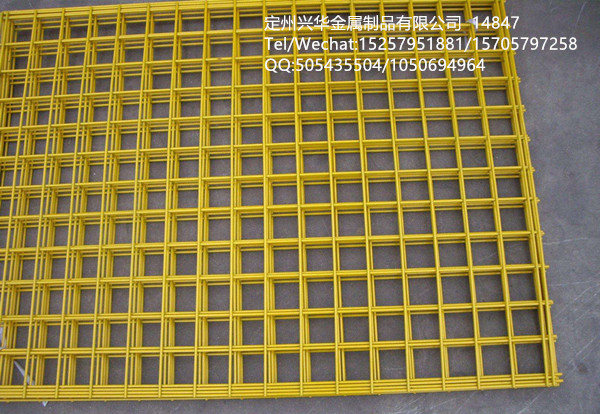

Electrical welding mesh is made of high-quality low-carbon steel wire and stainless steel wire, and the surface corrosion resistance of the welding mesh is divided into hot-dip galvanizing, electroplating zinc, PVC coating, immersion plastic, and special electrical welding mesh; It has strong corrosion resistance characteristics.

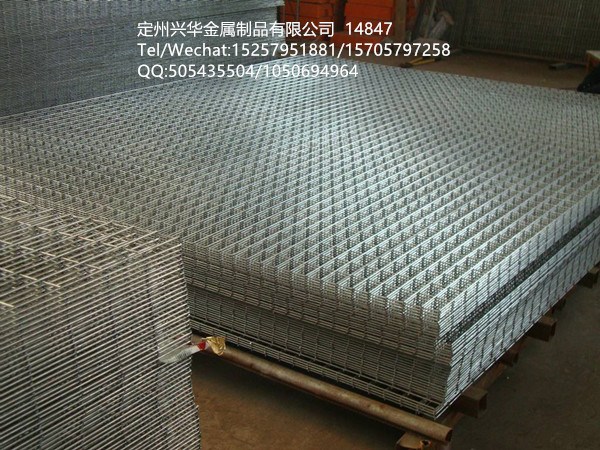

2. Manufacturing Process of Welded Wire Mesh: The process involves spot welding to form the mesh once, with manufacturing techniques divided into pre-welding coating and pre-coating welding; the coating process includes hot-dip galvanizing, cold-dip galvanizing, PVC coating, and immersion coating. It is produced by precision and accurate automated mechanical equipment for spot welding, resulting in a flat surface, uniform mesh, firm welds, variable mesh size and wire diameter, good local mechanical processing performance, stability, good corrosion resistance, and good anti-corrosion properties. It is characterized by resistance to acid and alkali, firm welding, beauty, wide application, etc.

Welded wire mesh is widely used in various industries, including: industrial, agricultural, construction, transportation, mining, sports fields, lawns, breeding, etc. It is used in fencing, decoration, and mechanical protection in various industries.

3. Classification of Welded Wire Mesh

Wire mesh for construction, electric welded mesh, stainless steel mesh, electric welded mesh, reinforcing mesh, reinforcing wire welding mesh, galvanized mesh, decorative mesh

For isolation and safety protection in places such as expressways, railways, municipal, residential communities, and factories.

4. The application of welded wire mesh

Mining welding mesh is made of low carbon steel wire spot welded, with the size of the mesh holes and the thickness of the wire diameter being adjustable. It can play a certain role in supporting in mine shafts, mine tunnels, and mine tunnels, with the welding mesh being strong and durable, with a long service life.

5. Welding Technology and Features of Wire Mesh

Welded mesh has good anti-corrosion characteristics and is widely used in construction engineering. The mesh has good stretching performance and welding performance. The welded mesh is precision woven by machine, with low cost and good welding technology, resulting in a uniform and solid mesh surface.

The welding process for electric welded mesh is also very demanding, especially for mesh made of stainless steel, which has strict requirements for the appearance of the mesh. The specific specifications and densities of the electric welded mesh are operated according to customer needs and drawings.

Produce according to customer requirements, please contact me if needed.

Tel/Wechat: 15257951881/15705797258

QQ:505435504/1050694964

Address: Shop 14847, 2nd Floor, 2nd Street, Gate 41, Zone 2, International Trade City

In addition, our factory deals in various types of wire mesh, nails, wire, woven wire mesh, and more.

Corner mesh, blade-type razor wire, Dutch mesh, tin plate bundling straps, window mesh

Welcome to inquire and purchase at any time, we look forward to a sincere and friendly cooperation with you~

Update time:

TOP