Contact us: Phone: 0579-85607545 Mobile phone: 15372908637 : 2360580307 Wishing you a pleasant shopping experience! 【Guangyue Accessory】 |

More surprises await you! |

Product Description:

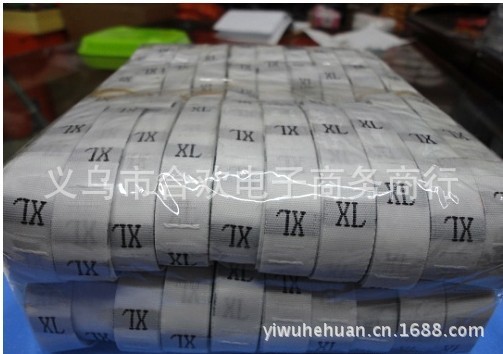

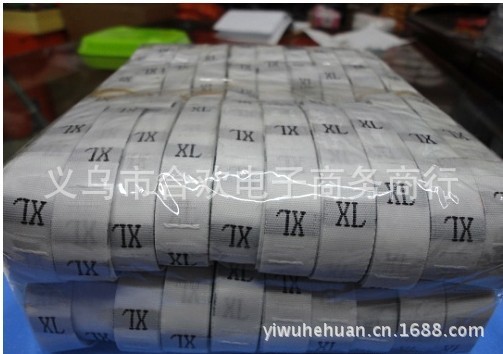

【Packing】: 500 pieces per roll, 20 rolls per package.The above is the price for one roll, with minor errors.

Specifications:Width: 1.2 cm, Length: 2.8 cm

【Type】: Banner

【Features】:Wash-resistant property,

【Workmanship】: Elegant

【Remark】: Application: Therefore, it is widely used in the textile industry, footwear, luggage, bedding, hats, toys, etc.

Contact customer service for other products:

Product Composition:

1label

Product alias:

Trademark, weaving label, weaving label, label head, inner label, washing label, washing label classification

The labels are mainly divided into two types: woven edges and cut edges.

Edge Stitching Label:

When the required trademark is indicated in one go according to the width requirements, it is called a woven border trademark. This process avoids many disadvantages of cutting edges, but the output is lower. There are also flat/satin types, with the characteristic of soft and firm touch. It is suitable for high-grade clothing products, such as fashion and suits, and is often used by Japanese manufacturers who pay attention to quality. The machines are also made in Japan. Woven border trademarks are usually made into satin trademarks, but it is difficult to express the satin background color. Commonly used processes such as heat setting/dyeing are used to solve this problem.

The machine for weaving borders generally includes wooden shuttle machines, and the color should not exceed four; there are also hook machines, which can also weave various quality crafts, and even can add transparent polyester yarn to the warp, which is called fish silk hook machine.

The cost composition of the fabric banner is not only related to the width, the total length of each color, and the process, but also to the type of yarn used. The JB series of yarn is commonly used internationally.

Cut-edge label:

Cut-edge label is also known as burned edge label.

As the name suggests, it is woven on a special high-speed machine, just like weaving a whole piece of cloth, and then cut into strips according to the width indicated. Because of the melting and fusing characteristics of polyester, the yarns tend to stick together when cut, resulting in no loose edges. This is also the reason why the appearance and feel are somewhat affected. Good machines will be better, and using ultrasonic cutting is better than ordinary electric heating knives. The strips of cloth labels can be directly processed and sent to the garment factory for processing; if the requirements are strict, further cutting and folding processing is still needed. Because this machine has a large width of 20.8cm, it means that labels of this width can be woven, and therefore various shapes can be processed.

According to the classification of technology, it can be divided into two major categories: flat labels and satin labels.

Satin Label:

The concept of satin has been mentioned in the previous places, but there is no detailed introduction. The cloth is made by interlacing the warp and weft. Apart from improving the quality by doubling the weft yarn, another method is to double the warp yarn, which is the satin structure. After doubling the warp yarn, the texture of the cloth becomes soft and smooth. Because the density becomes too large after doubling the warp yarn, the weft yarn cannot express the pattern well, and the base color cannot be very flexible. It can only show a certain color requirement through the subsequent process. Whether a machine is set to do a plane or a satin is generally relatively fixed. The width of the satin with a cut edge generally cannot exceed 10.8CM, and the width of the one with a woven edge generally will not exceed 5.0CM.

Usage: Due to the water-resistant characteristics of the fabric label, it is often used in the textile industry, footwear, luggage, bedding, hats, toys, and other fields.