Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

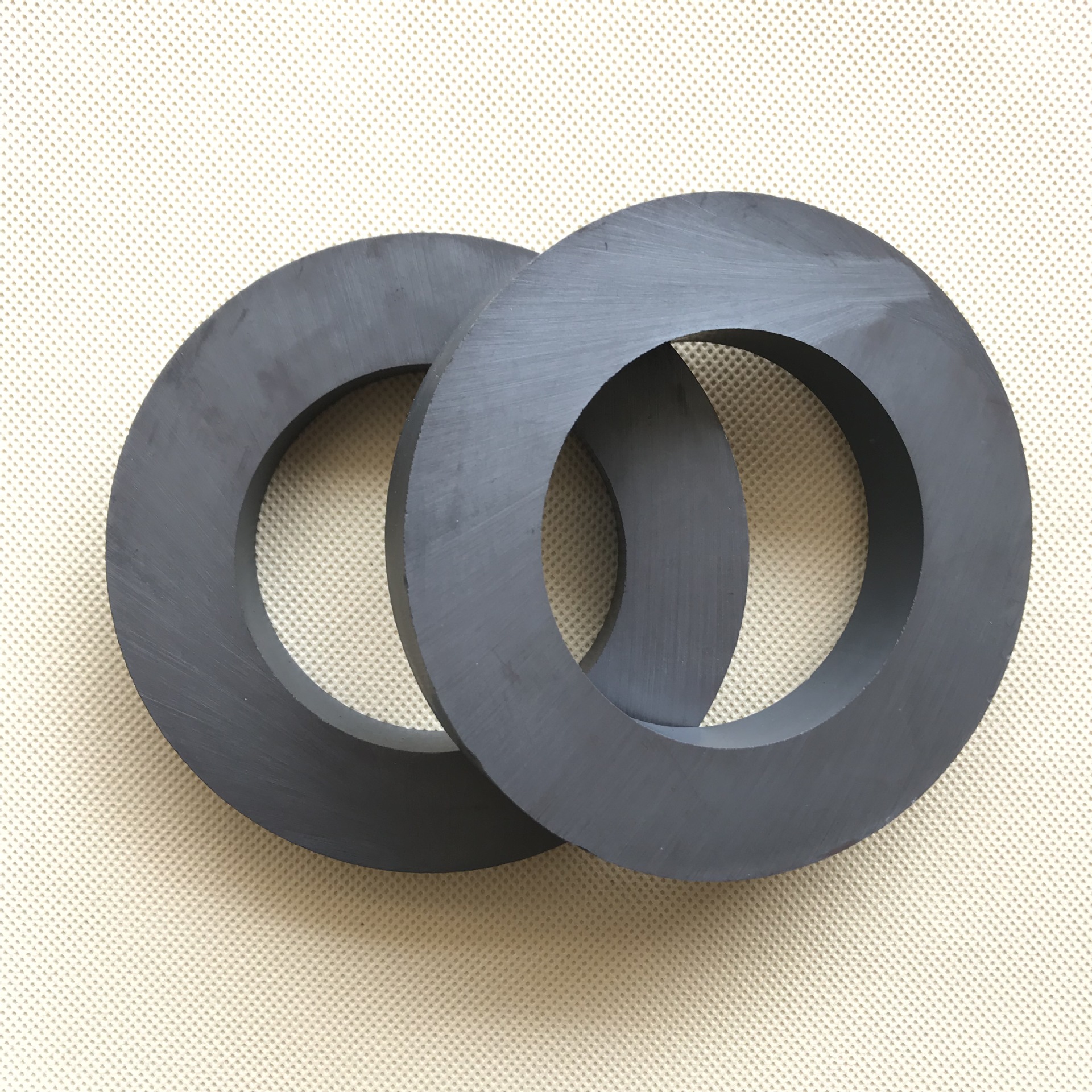

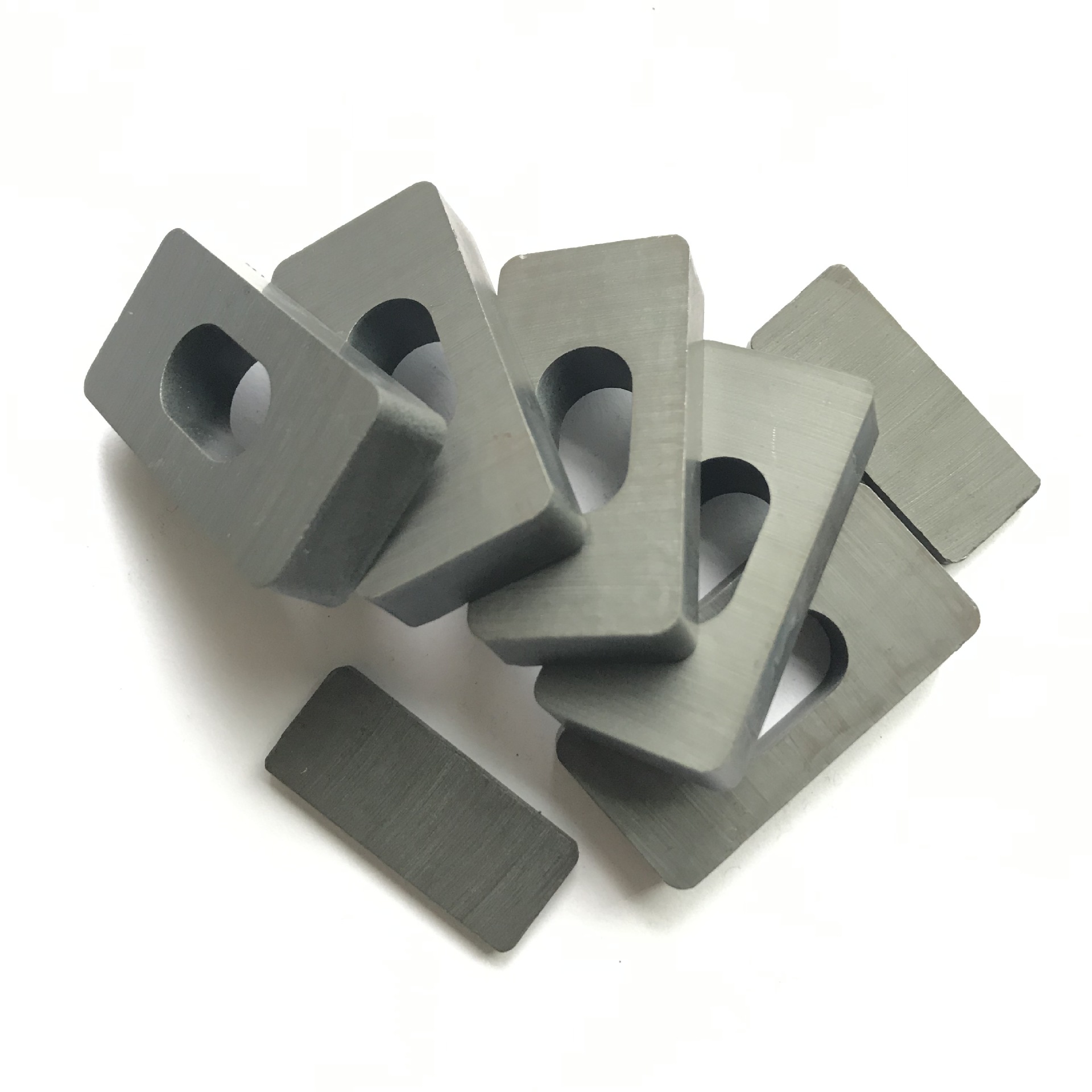

The specifications produced by our company include ferrite magnets such as round, square, toroidal, irregular patterns, etc., can be produced customization as request. All our magnet sizes are measured in millimeters..

Magnetic ring existing specifications:

16*7*5 23*13*7 30*18*6 32*18*8 35*18*8 36*18*8 40*19*8 40*22*8 45*19*10 45*16*8 45*22*10 50*16*8 50*22*8 50*25*10 55*25*10 55*22*10 55*32*8 58*32*8 60*32*8

70*32*15 80*32*10 80*40*12 100*45*20 100*60*20 120*60*20 156*80*20 square with hole horn magnetic F45 * 25-18*8 F45 * 25-16*8 F30 * 21-12.9*7 F50 * 29-21*8 62*29-18*8 you can customize the following table by performance.

Ferrite table of standard performance

|

Brand Grade |

Remanence (Br) |

Magnetic coercive force (HcB) |

Intrinsic coercive force (HcJ) |

Maximum magnetic energy product (BH)max |

||||

|

mT |

KGauss |

KA/m |

KOe |

KA/m |

KOe |

KJ/m3 |

MGOe |

|

|

Y10T |

200~235 |

2.0~2.35 |

125~160 |

1.57~2.01 |

210~280 |

2.64~3.51 |

6.5~9.5 |

0.8~1.2 |

|

Y20 |

320~380 |

3.20~3.80 |

135~190 |

1.70~2.38 |

140~195 |

1.76~2.45 |

18.0~22.0 |

2.3~2.8 |

|

Y22H |

310~360 |

3.10~3.60 |

220~250 |

2.76~3.14 |

280~320 |

3.51~4.02 |

20.0~24.0 |

2.5~3.0 |

|

Y25 |

360~400 |

3.60~4.00 |

135~170 |

1.70~2.14 |

140~200 |

1.76~2.51 |

22.5~28.0 |

2.8~3.5 |

|

Y26H |

360~390 |

3.60~3.90 |

200~250 |

2.51~3.14 |

225~255 |

2.83~3.20 |

23.0~28.0 |

2.9~3.5 |

|

Y27H |

370~400 |

3.70~4.00 |

205~250 |

2.58~3.14 |

210~255 |

2.64~3.21 |

25.0~29.0 |

3.1~3.7 |

|

Y30 |

370~400 |

3.70~4.00 |

175~210 |

2.20~3.64 |

180~220 |

2.26~2.76 |

26.0~30.0 |

3.3~3.8 |

|

Y30BH |

380~390 |

3.80~3.90 |

223~235 |

2.80~2.95 |

231~245 |

2.90~3.08 |

27.0~30.0 |

3.4~3.7 |

|

Y30H ~ 1 |

380~400 |

3.80~4.00 |

230~275 |

2.89~3.46 |

235~290 |

2.95~3.64 |

27.0~32.5 |

3.4~4.1 |

|

Y30H ~ 2 |

395~415 |

3.95~4.15 |

275~300 |

3.45~3.77 |

310~335 |

3.89~4.20 |

27.0~32.0 |

3.4~4.0 |

|

Y32 |

400~420 |

4.00~4.20 |

160~190 |

2.01~2.39 |

165~195 |

2.07~2.45 |

30.0~33.5 |

3.8~4.2 |

|

Y33 |

410~430 |

4.10~4.30 |

220~250 |

2.76~3.14 |

225~255 |

2.83~3.21 |

31.5~35.0 |

4.0~4.4 |

|

Y35 |

400~410 |

4.00~4.10 |

175~195 |

2.20~2.45 |

180~200 |

2.26~2.51 |

30.0~32.0 |

3.8~4.0

|

Permanent magnet introduction and main features of ferrite:

Magnetic materials are basic functional materials in the electronics industry. As an important component of magnetic materials, permanent magnet materials play an important role in electronic industry, information industry, motorcycle, electric tool industry, automobile industry and other industries. Permanent magnet ferrite material is the functional material that generates magnetic field. Because its raw material price is cheap and its production process is relatively simple, its finished product price is relatively low compared with other magnets. The main raw material of ferrite magnet is oxide, so it is not affected by environment or chemicals (except strong acid) and corrodes, so the surface does not need electroplating treatment. It is the most widely used permanent magnet material, which is made by powder metallurgy and is mainly divided into barium material (Ba) and Reed material (Sr), it is divided into two types: anisotropic and isotropic. It is a permanent magnet material that is not easy to demagnetize and not easy to corrode. The maximum working temperature can reach 250℃, which is relatively hard and brittle, diamond sand and other tools can be used for cutting and processing, and the alloy just processed mold is used for one molding. Such products are mainly used in handicrafts, suction accessories, toys, motors, speakers, etc.

It is made by powder metallurgy-chemical combination-Ba/Sr O6 FeO-relatively hard and brittle-not easy to Demagnetization-very good corrosion resistance-low price, rich sources-good temperature stability-the most widely used permanent magnet production process of permanent magnet ferrite: ingredients ----> pre-burning ----> crushing ----> ball milling ----> milling ----> dry pressure magnetic field forming/dry pressure forming/wet pressure magnetic field forming -----> sintering ----> mechanical processing ----> inspection ----> packaging

Factory Address: Dongyang Hengdian industrial zone

24-hour customer service online: 13989445063 WeChat with the same number

Update time:

TOP