Click to Contact Yiwugo official customer service for International sourcing.

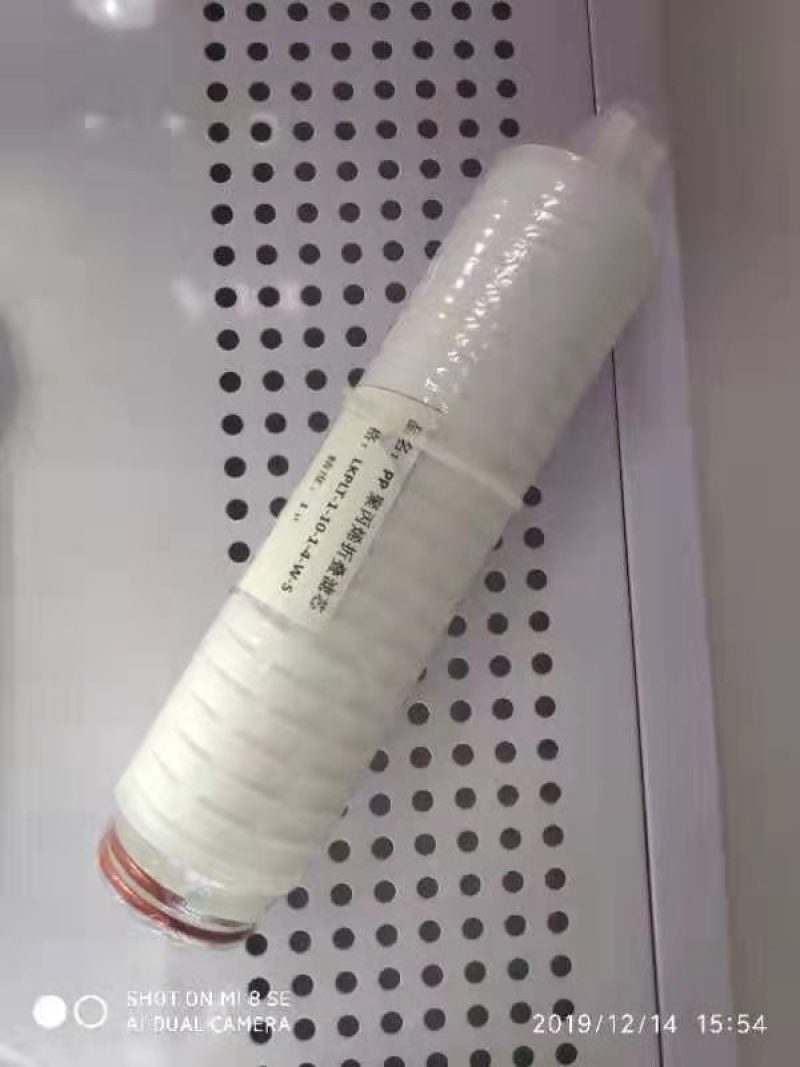

Folding filter element 5 " to 30"

Folded filterisSecurity filter elementIncluding :PP folding filter element, polyethersulfone folding filter element, polytetrafluoroethylene folding filter element, neyou membrane folding filter element,High flow filter element

PP folding filter element is a kind of filter material commonly used in water treatment. 10 inches, 20 inches, 30 inches, 40 inches,

It is made from polypropylene PP film, non-woven fabric and PP skeleton,

The pore size is distributed in a gradient along the direction of filtrate, which integrates surface, deep layer and coarse fine filtration, and can intercept impurities with different particle sizes.

Performance:

Wide chemical compatibility, large circulation, low pressure difference, long service life.

Wide range of filtering precision, large selection, can meet a variety of applications.

Using hot melt technology, firm and no release pollution products.

It can be cleaned by ordinary method and sterilized by autoclave and steam.

USES:

Electronic industry: reverse osmosis water system pre-filtration, deionized water system pre-filtration.

Food industry: filtration of beverage, liquor, mineral water, purified water, etc.

Chemical industry: filtration of organic solvents, inks, etc.

Pharmaceutical industry: filtration of pharmaceutical, biological and plasma products, and filtration of compressed air and gas.

Others: electroplating solution, metal cutting fluid, photoresist and magnetic media filtration.

Usage:

1 moisten the o-ring, slowly insert the filter element vertically, all of which must be inserted into the stainless steel circular groove.

2. Press the fins of the filter element well with the stainless steel orifice plate. The pressing plate should not be too tight to prevent the filter element from changing shape during high-temperature disinfection.

3 avoid direct contact with the filter element by hand.

4. Wash the filter element as much as possible before use.

5 when starting or shutting down, please turn the valve slowly, do not open or close at once, to prevent the filter from being sucked in the high temperature disinfection.

Maintenance:

Filter used to cannot satisfy the design discharge (flow markedly reduced differential pressure gauge at 0.1 MPa) before and after, please open the filter from the filter after downtime, removed from filter, rinse the surface of stolen goods, and then in the first 4% of hydrochloric acid soaking for 24 hours, and then soaked in 4% sodium hydroxide for 24 hours, after rinse (soak off two o-rings, to prevent inflation).

Storage method:

1 soak the filter element in disinfectant and fill the stainless steel case of the filter with disinfectant.

2. Remove and dry the filter element (50oC 36h)

3 take out the filter element and dry it in a dry climate.

Please do not pack the filter element in plastic bag to prevent mildew.

Update time:20210717154133