Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Zhejiang Yubu Electric Co., LTD 8yr.

Contacts:Huang Huahua Chat

Mobile:86-18867711136

E-mail:619588251@qq.com

Product Introduction

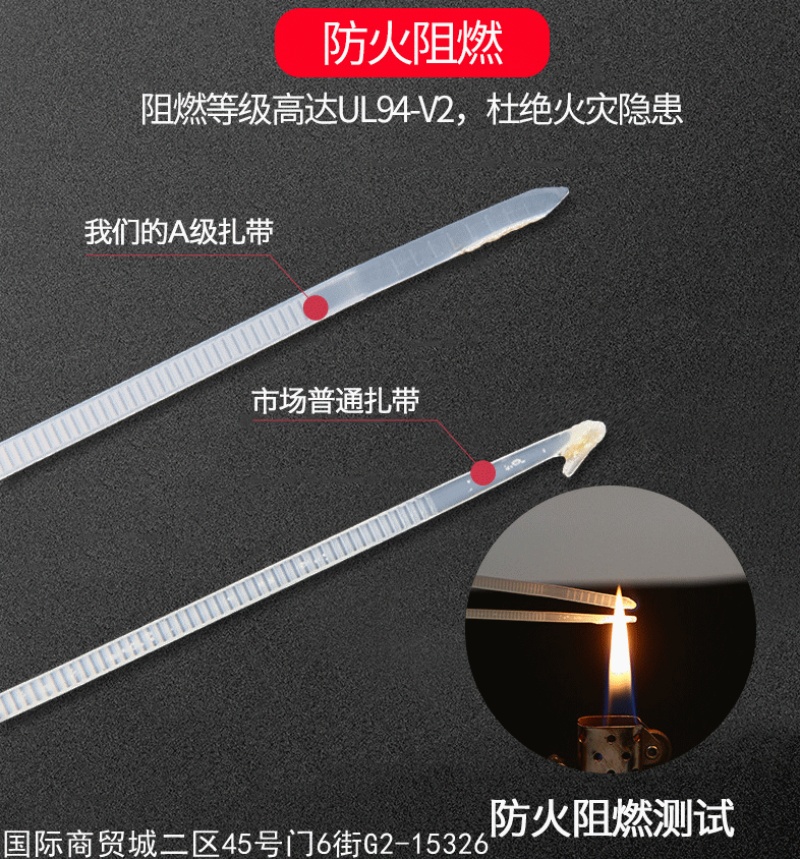

Nylon tie straps are UL approved.Nylon-66The material is made of nylon 66, with a fire resistance rating of 94V-2, showing good resistance to acid, corrosion, and insulation, and is not easily aged or damaged. It can operate at temperatures ranging from -20°C to +80°C (for ordinary nylon 66). It is widely used in the fixed internal wiring of electronic factories, television and computer bundles, and in the fixed internal wiring of products such as lighting, motors, and electronic toys. It is also used for the fixed oil pipelines in mechanical equipment, the fixed cable lines on ships, and the bundling or tying of other objects for bicycles. It can also be used for the bundling of agricultural, horticultural, and handicraft items. This product features fast tying, good insulation, self-locking fastening, and convenience in use.

Widely used in Christmas gift factories, electronic factories, wire processing plants, electrical cables, toy factories, festive holidays, stationery and general merchandise, fresh food supermarkets, household daily use, electrical workers and electrical appliances, connectors and other items.The most important evaluation focus of nylon tie is its breaking force. When applied to a certain force, whether the tie breaks or the teeth reverse, or the head cracks, the breaking method must be above the nominal tensile strength. As for some users feeling that the quality of the tie is poor, it is also partly related to the selected specification. One cannot be stubborn and think that the tie quality is poor because the product standard tensile strength of a specification is predetermined. When the required force in the use condition exceeds the standard greatly, it cannot be guaranteed. It can only be replaced by choosing a higher tensile strength specification product. Of course, the cost will increase, which is inevitable. Of course, the good quality tie stretch is flexibility.ExtensibilityExcellent, there will be no direct and clear fracture section, and it will not be brittle. This can also meet the user's requirements for the scope of application of the tensile force to a greater extent, thereby achieving the possibility of reducing costs.

Widely used in Christmas gift factories, electronic factories, wire processing plants, electrical cables, toy factories, festive holidays, stationery and general merchandise, fresh food supermarkets, household daily use, electrical workers and electrical appliances, connectors and other items.The most important evaluation focus of nylon tie is its breaking force. When applied to a certain force, whether the tie breaks or the teeth reverse, or the head cracks, the breaking method must be above the nominal tensile strength. As for some users feeling that the quality of the tie is poor, it is also partly related to the selected specification. One cannot be stubborn and think that the tie quality is poor because the product standard tensile strength of a specification is predetermined. When the required force in the use condition exceeds the standard greatly, it cannot be guaranteed. It can only be replaced by choosing a higher tensile strength specification product. Of course, the cost will increase, which is inevitable. Of course, the good quality tie stretch is flexibility.ExtensibilityExcellent, there will be no direct and clear fracture section, and it will not be brittle. This can also meet the user's requirements for the scope of application of the tensile force to a greater extent, thereby achieving the possibility of reducing costs.

Update time:

TOP