Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Zhejiang Yubu Electric Co., LTD 8yr.

Contacts:Huang Huahua Chat

Mobile:86-18867711136

E-mail:619588251@qq.com

Product Introduction

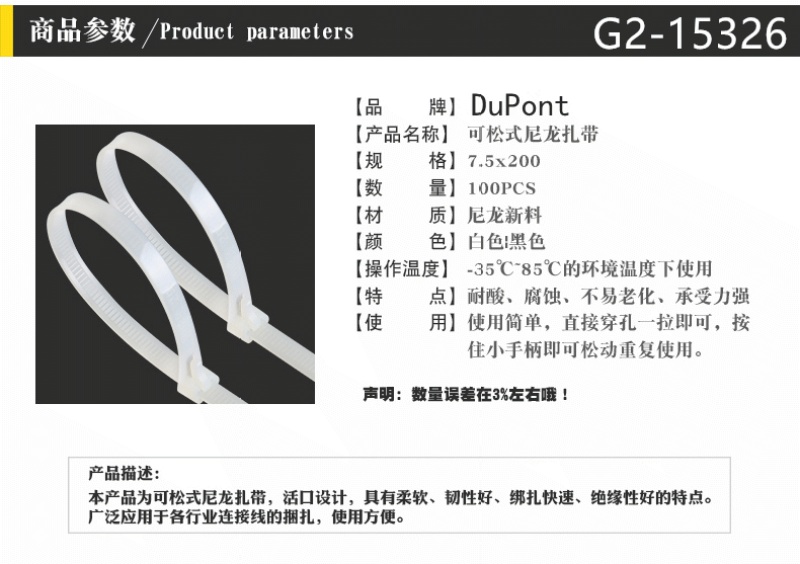

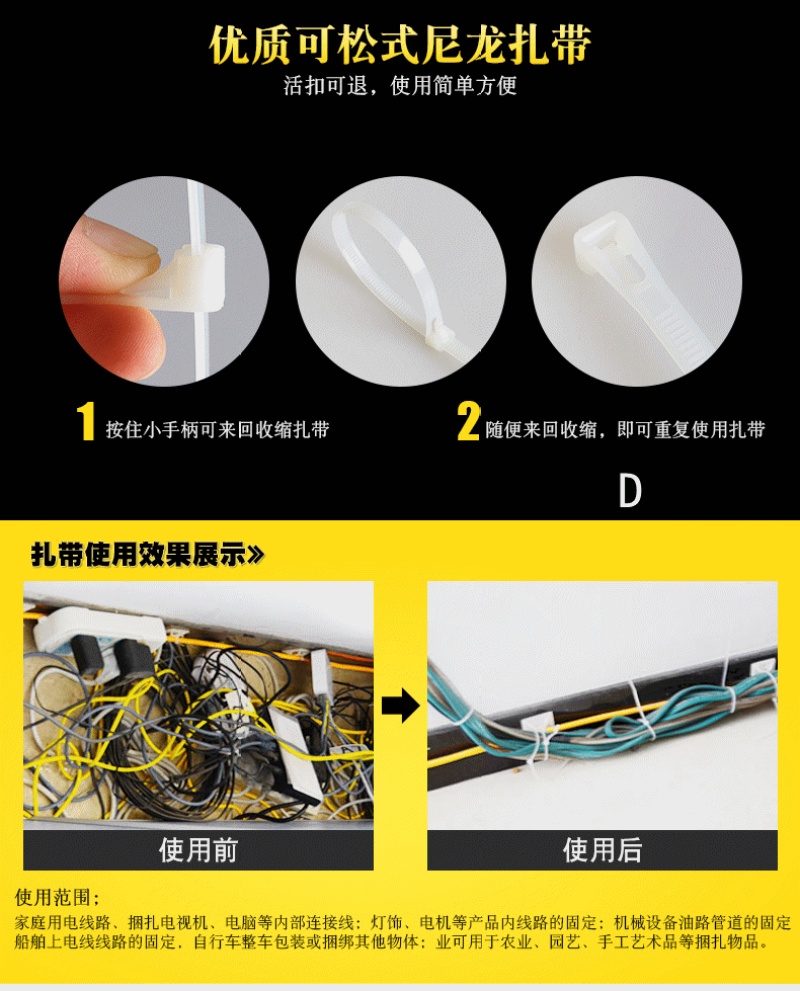

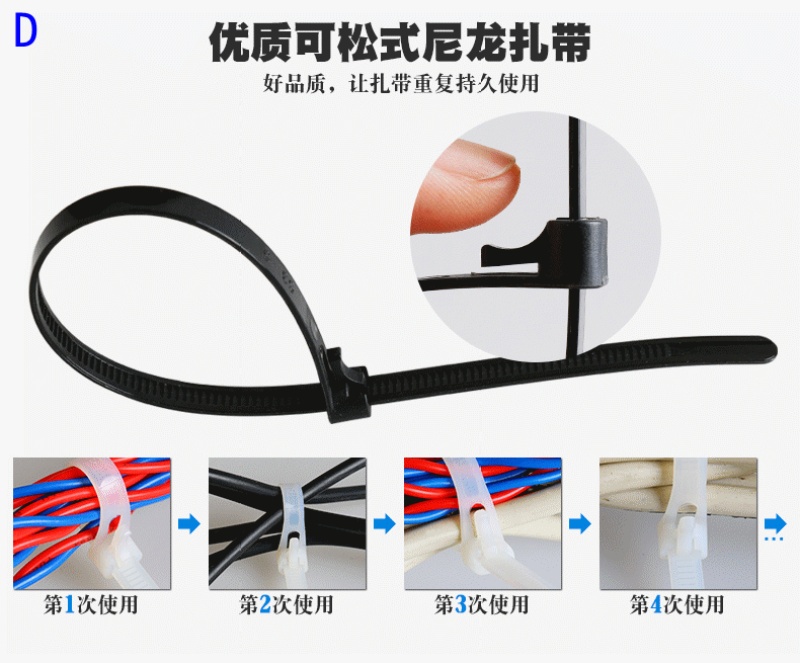

Why are some nylon tie specifications such as 2.5*100, 3.6*200, and 4.8*300, while others are 3*100, 4*200, and 5*300? What is the difference? The best answer: Accurately speaking, 2.5*100, 3.6*200, and 4.8*300 (with decimal points) are actual dimensions, meaning the actual widths are 2.5MM, 3.6MM, and 4.8MM, respectively. Whereas 3*100, 4*200, and 5*300 are nominal dimensions, which are just a way of referring to them. The numbers 3, 4, and 5 do not represent the actual widths. For example, an item with an actual width of 2.0MM and a length of 100MM can be called 3*100, and an item with an actual width of 2.5MM and a length of 100MM can also be called 3*100. Before the mass commercialization of nylon zip ties, traditional techniques for securing wires or objects usually involved using ropes or twine, also known as "zipping."Zhā Sī。 Traditional rope and knotting techniques are gradually being phased out of the market, and more and more enterprises and factories are preferring to use nylon tie straps. This involves several aspects. 1. Traditional rope and twine are usually made of PVC or fiber materials, but these materials tend to deteriorate or rot over time, causing inconvenience for the items after use. 2. For example, traditional PVC binding wire, which requires iron wire to strengthen its toughness and tension, may have its surface peeling or aging over time. If the iron wire is exposed, it can pierce objects directly, and if used in electrical wires and appliances, it poses a risk of electrical conductivity. 3. Whether it is a rope or traditional tying wire, it is quite troublesome in actual operation, and the scale of workers' operation is also difficult to be uniform, resulting in higher labor costs. However, the use of self-locking nylon tying straps is relatively simple, and the uniform scale of use method brings higher efficiency to the enterprise. 4. Nylon tie wires have high tensile strength and impact resistance, and they are also resistant to acids and alkalis. Additionally, in industrial applications, nylon has a certain fire-retardant rating that can reach 94V2. All of these advantages are not present in traditional ropes and tie wires. 5. In recent years, especially in Europe, the environmental protection requirements proposed have made it difficult for traditional PVC materials to meet the standards set by the EU. Additionally, because traditional binding wire requires a large amount of iron wire, the rising prices of steel in our country have escalated one after another, and there is a certain risk in terms of price, so it has lost its market. The above review indicates that the nylon tie market has a relatively stable development prospect.

The most important evaluation focus of nylon tie is its breaking force. When applied to a certain force, whether the tie breaks or the teeth reverse, or the head cracks, the breaking method must be above the nominal tensile strength. As for some users feeling that the quality of the tie is poor, it is also partly related to the selected specification. One cannot be stubborn and think that the tie quality is poor because the product standard tensile strength of a specification is predetermined. When the required force in the use condition exceeds the standard greatly, it cannot be guaranteed. It can only be replaced by choosing a higher tensile strength specification product. Of course, the cost will increase, which is inevitable. Of course, the good quality tie stretch is flexibility.ExtensibilityExcellent, there will be no direct and clear fracture section, and it will not be brittle. This can also meet the user's requirements for the scope of application of the tensile force to a greater extent, thereby achieving the possibility of reducing costs.

The most important evaluation focus of nylon tie is its breaking force. When applied to a certain force, whether the tie breaks or the teeth reverse, or the head cracks, the breaking method must be above the nominal tensile strength. As for some users feeling that the quality of the tie is poor, it is also partly related to the selected specification. One cannot be stubborn and think that the tie quality is poor because the product standard tensile strength of a specification is predetermined. When the required force in the use condition exceeds the standard greatly, it cannot be guaranteed. It can only be replaced by choosing a higher tensile strength specification product. Of course, the cost will increase, which is inevitable. Of course, the good quality tie stretch is flexibility.ExtensibilityExcellent, there will be no direct and clear fracture section, and it will not be brittle. This can also meet the user's requirements for the scope of application of the tensile force to a greater extent, thereby achieving the possibility of reducing costs.

Update time:

TOP