Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Xuemei internation Co., ltd 15yr.

Contacts:Zhao Xuemei Chat

Mobile:86-18266901568

E-mail:hzhongmei@hzhongmei.com

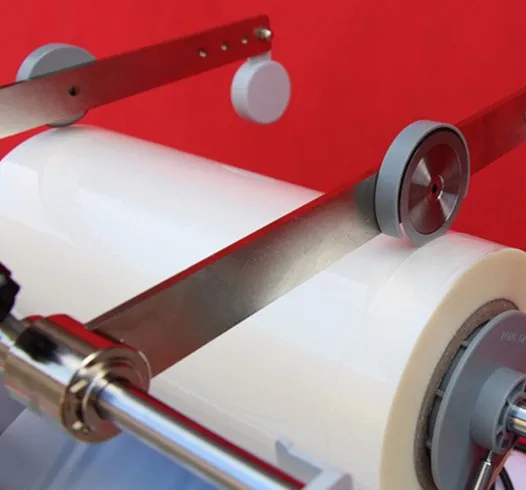

A heated roll laminator uses heated rollers to melt glue extruded onto lamination film. This film is in turn applied to a substrate such as paper or card using pressure rollers. The primary purpose of laminating with such a machine is to embellish or protect printed documents or images. Heated roll laminators can vary in size from office based pouch laminators to industrial sized machines. Such industrial machines are primarily used for high quantity/quality output by printers or print finishers.

Whether small office or industrial machines their primary function is to embellish or protect printed works. Such laminators are used to apply varying thicknesses of lamination film onto substrates such as paper or fabrics. The main advantage to the use of heated roll laminators is that of speed. Heated laminators use heated rollers or heated shoes to melt the glue which is applied to lamination film. The process of heating the glue prior to applying the film to a substrate allows for a faster application of the film. The laminates and adhesives used are generally cheaper to manufacture than cold roll laminates, often as much as half the cost depending on the comparison made. As the materials are non-adhesive until exposed to heat, they are much easier to handle. The glue is solid at room temperature, so lamination of this type is less likely to shift or warp after its application than pressure activated laminates, which rely on a highly viscous, adhesive fluid

|

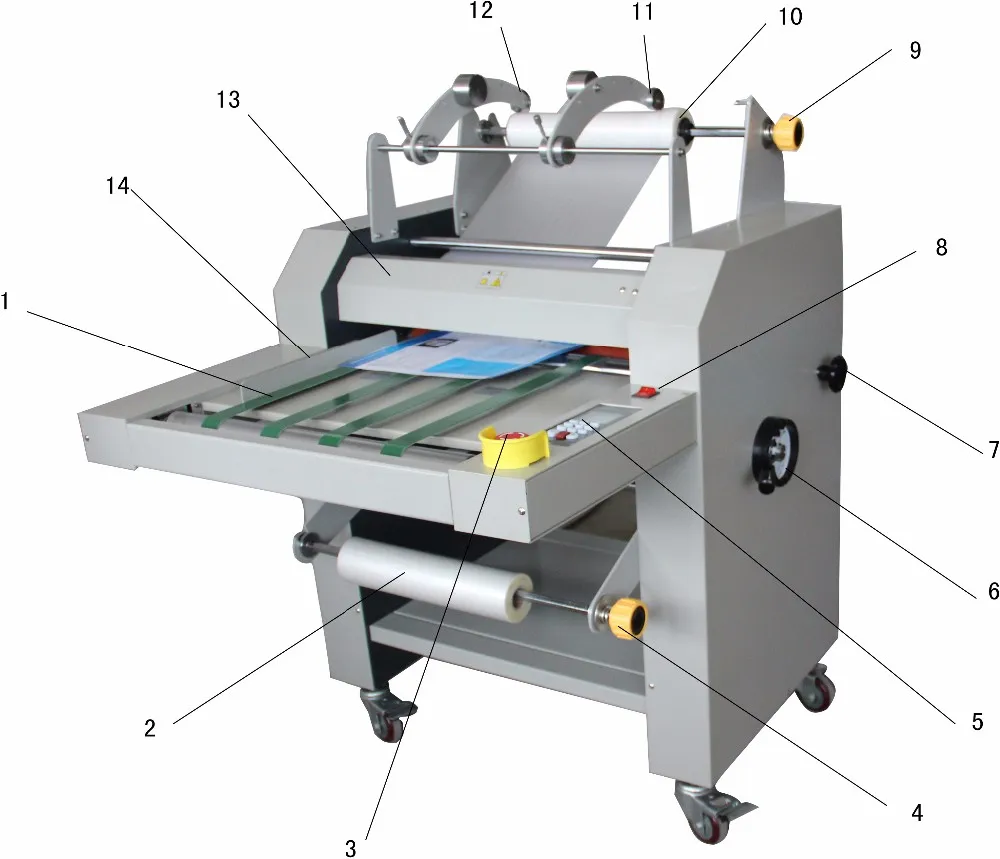

SPECIFICATIONS FOR SG-490 laminating machine

|

|

|

|

|

|

Power supply

|

AC210V~230V(50HZ) AC110V(60HZ)

|

|

Power consumption

|

2200W

|

|

Max. Laminate width:

|

490mm

|

|

Laminate Thickness:

|

60-800gsm

|

|

Max. Laminate speed:

|

10m/min

|

|

Warming up time:

|

10min

|

|

Suggested laminate bopp film:

|

25-250mic

|

|

Max. temperature:

|

150 degree

|

|

Operating panel:

|

LCD screen

|

|

Auto feed paper with belt:

|

Yes

|

|

Single/Double Laminate:

|

Yes

|

|

Cold&Hot Laminate:

|

yes

|

|

Cut film knife:

|

Yes

|

|

Perforatingknife: Yes knife:

|

Yes

|

|

Auto rewinding paper:

|

Yes

|

|

Dia. of core:

|

1",1.5",3"

|

|

Reverse:

|

Yes

|

|

The quantity of roller:

|

4pcs

|

|

Speed control:

|

9 gear

|

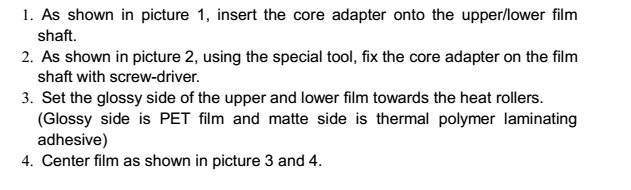

1) Simple structure in linear type ,easy in installation and maintation.

2) can be both cold and hot laminating

3) can be single and double side laminating

4) Running in a high automatization and intellectualization,no pollution .

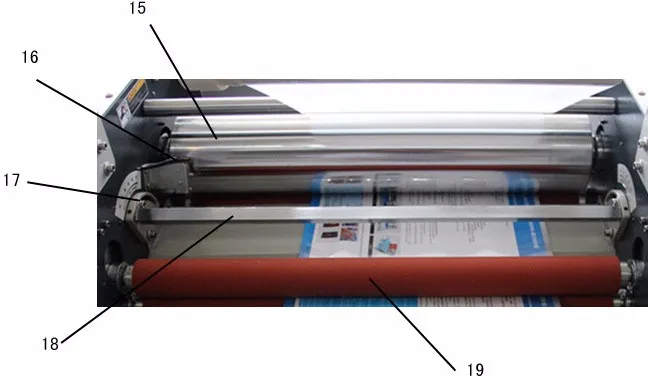

1.Turn on the switch.

2.Follow the steps in the "Loading Film" procedure by loading the upper shaft

with OPP Film

3. Set heating roll temperature according to film thickness

4.Turn on the protect cover

5. Adjust the PRESSURE LEVER to UP

6.Insert and push the leader board until board reaches pull rollers

7.Adjust the position of the perforating blade on the film (1-2mm)

8.Fix the position of round blade according to the width of the document (1-2mm)

9.Please stick the excess film to the roller

Update time:

TOP