Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Wuyi Huatai reflective material Co., Ltd. 12yr.

Contacts:Luo Huafeng Chat

Mobile:86-13868948585

E-mail:634229946@qq.com

Product Introduction:

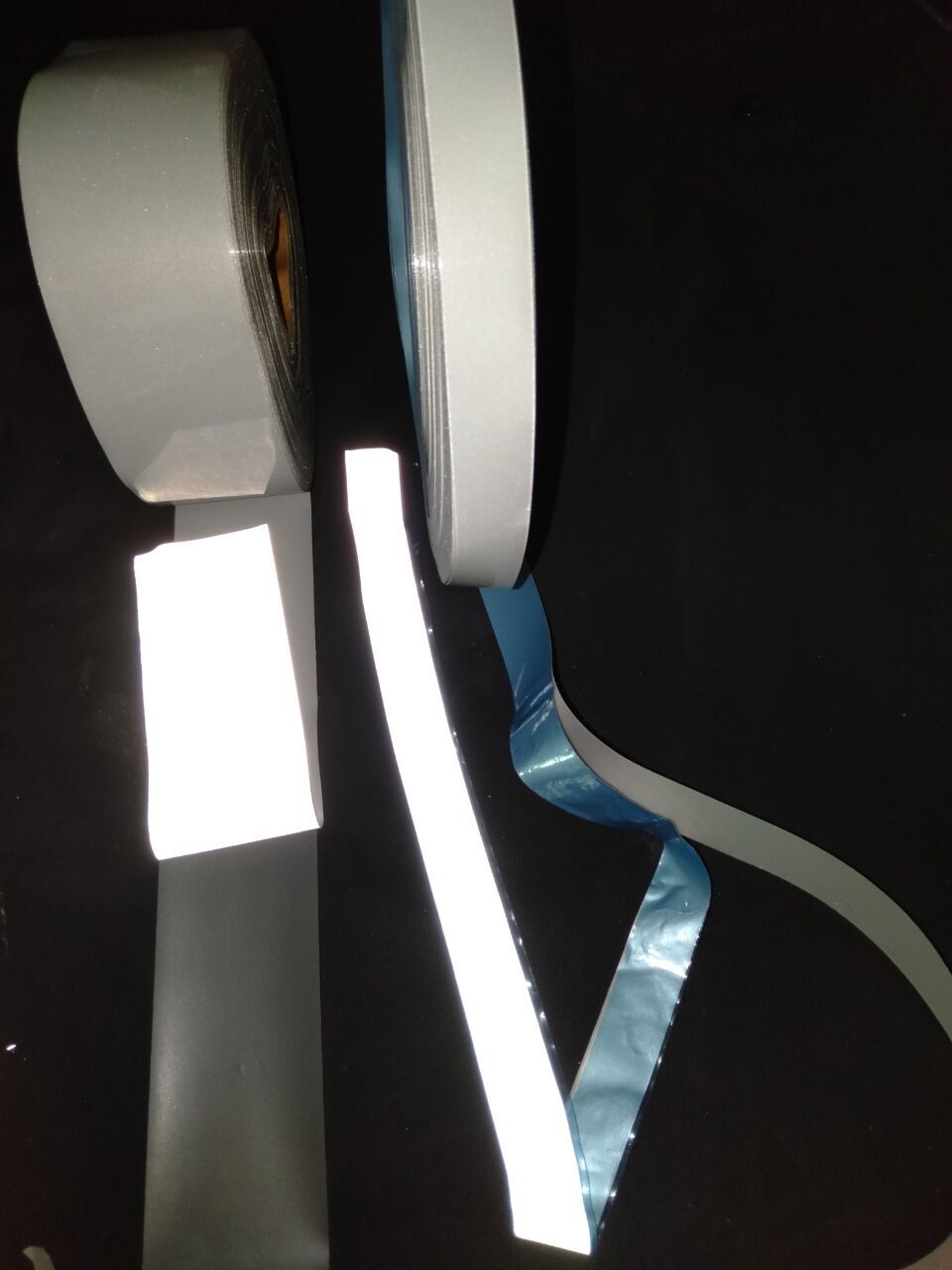

Reflective MarkingsIt is composed of reflective glass microspheres bonded to various thermosensitive adhesives.Its back is a heat-sensitive adhesive layer, and it has a protective layer on both sides. After being heated and adhered to the fabric surface, it has a very obvious effect on improving the wearer's visibility in low-light or poor visibility environments!

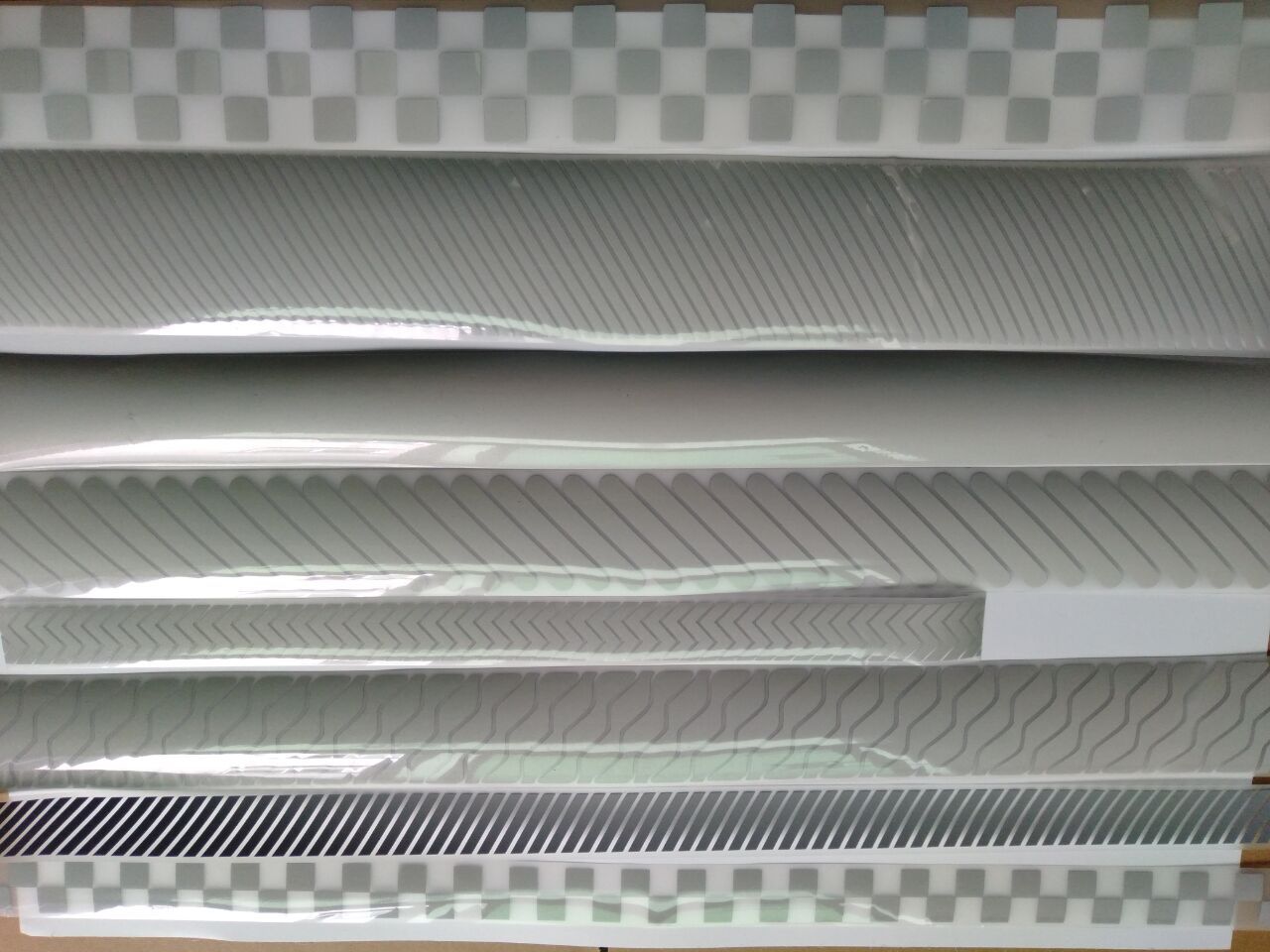

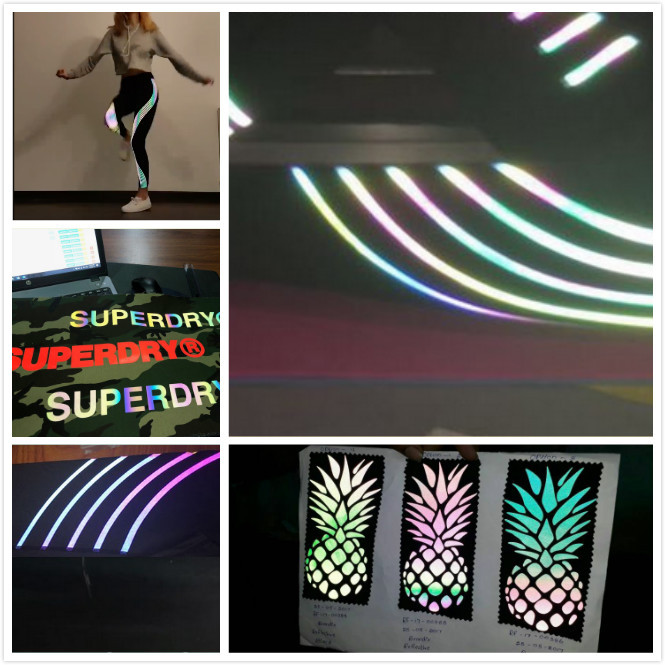

The carved film texture is special, and the product must be used with a computer engraving machine and heat transfer machine. It is very convenient, and it can also be used for multi-color transfer to increase the richness and variability of the product. It is not limited to the color of the fabric, as long as it is fabric material, it can be transferred. After transfer, it has superior wash color fastness and adhesive strength. This product is widely used in single-color graphics, personalized casual wear, sportswear, hats, gloves, backpacks, etc.!

| Name | Reflective transfer label, reflective engraving label |

| Product Composition |

The first layer is a PET protection layer, the second layer is a glass bead layer, and the third layer is a reflective layer. The fourth layer is the polyester hot-melting adhesive layer, and the fifth layer is the backing film layer. |

| Specification | The thickness is 0.13mm/0.16mm (excluding the thickness of the protective film), and the regular width is 1 meter. It can be custom-made to 1.37M and can be cut. |

| Characteristics | High anti-glare, good effect, soft touch, strong three-dimensional sense, convenient transfer, durable and washable, eco-friendly |

| Characteristics |

1, Pattern size: Whether it's a large pattern or a small one as fine as hair, it can be easily transferred. 2, PET non-stick fabric: Whether it's mesh fabric or bristle fabric, it's completely non-stick. It doesn't bite the fabric, and the release is light. 3, the arrangement of glass beads is more dense, and the edge of the heat transfer pattern is more neat. The wide-angle reflection is better. |

| Application | Widely used in monochrome graphics, this material is also used in personalized casual wear, sportswear, hats, gloves, and backpacks! |

Product:

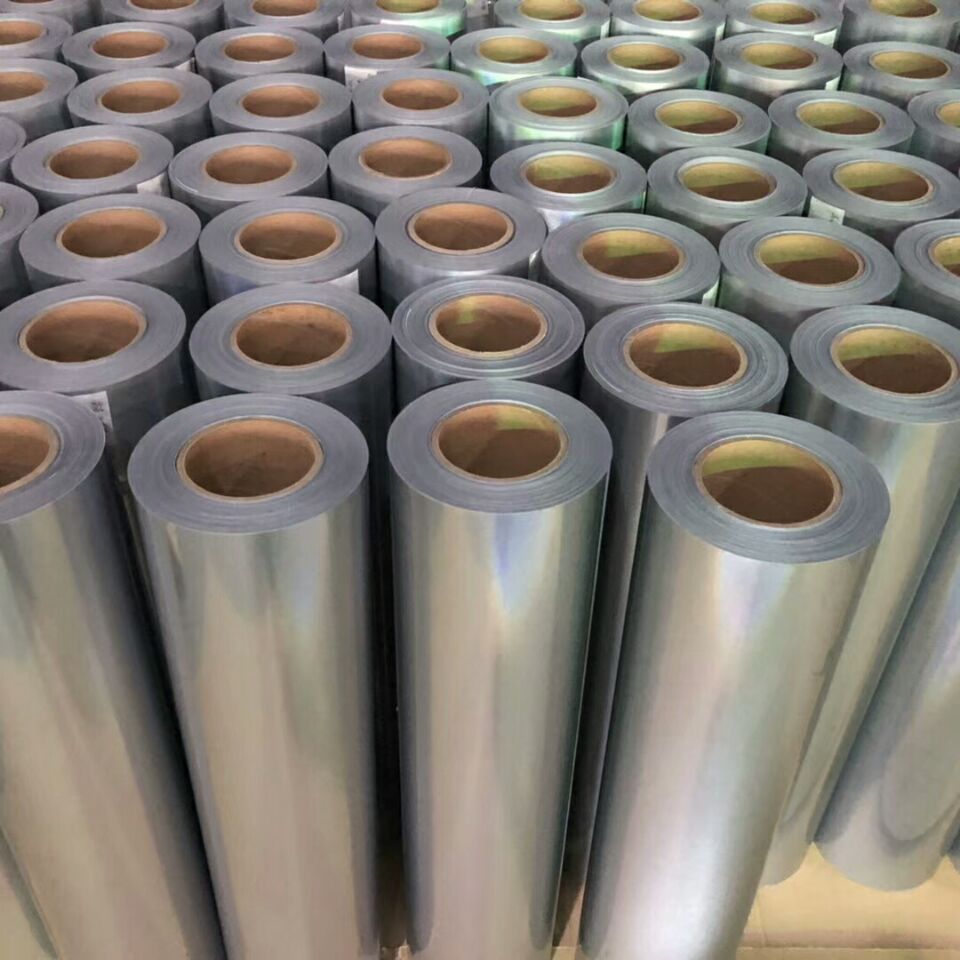

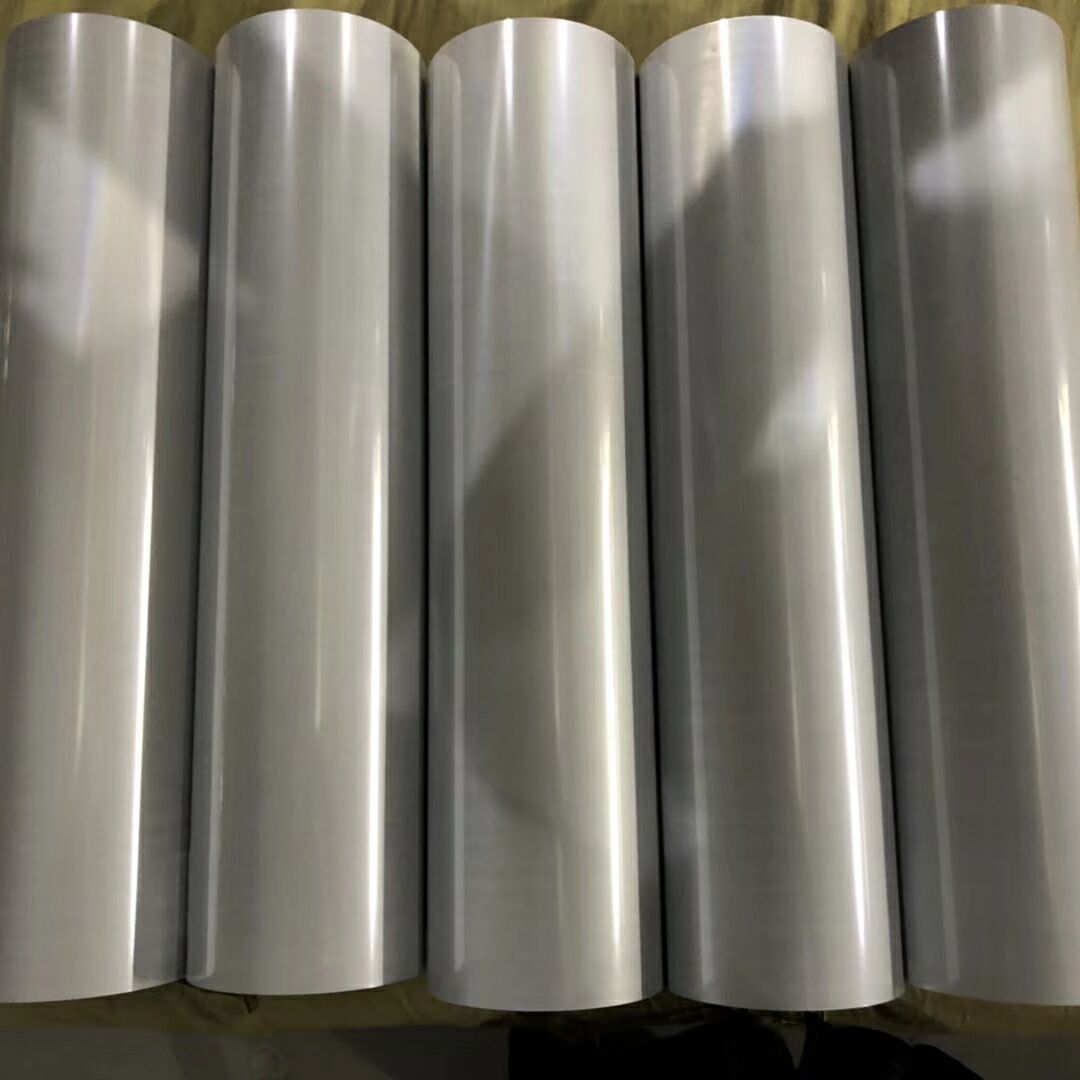

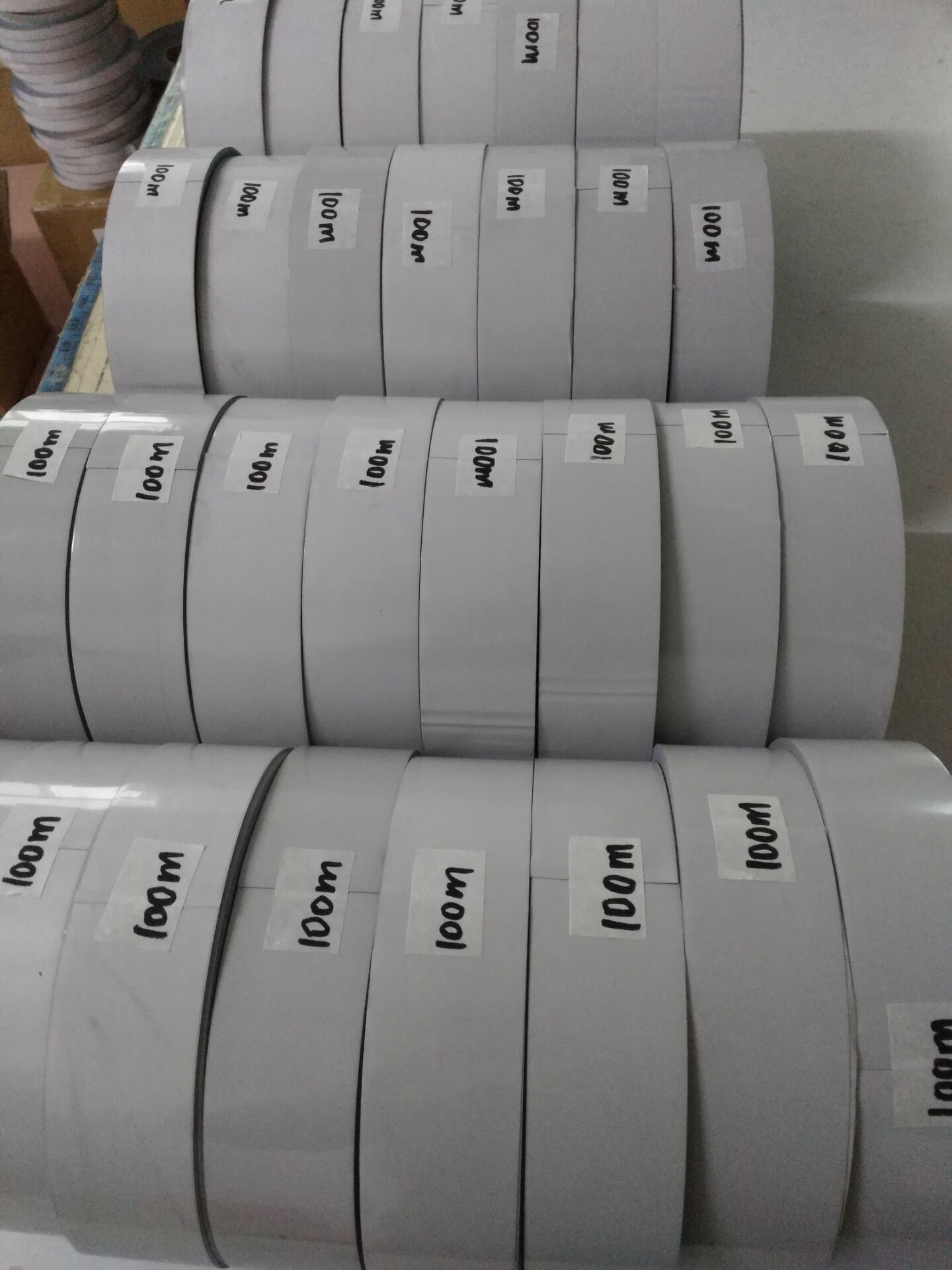

Silver reflective engraving film, silver reflective transfer film:

Silver reflective labels can be directly heat transferred to clothing and bags.

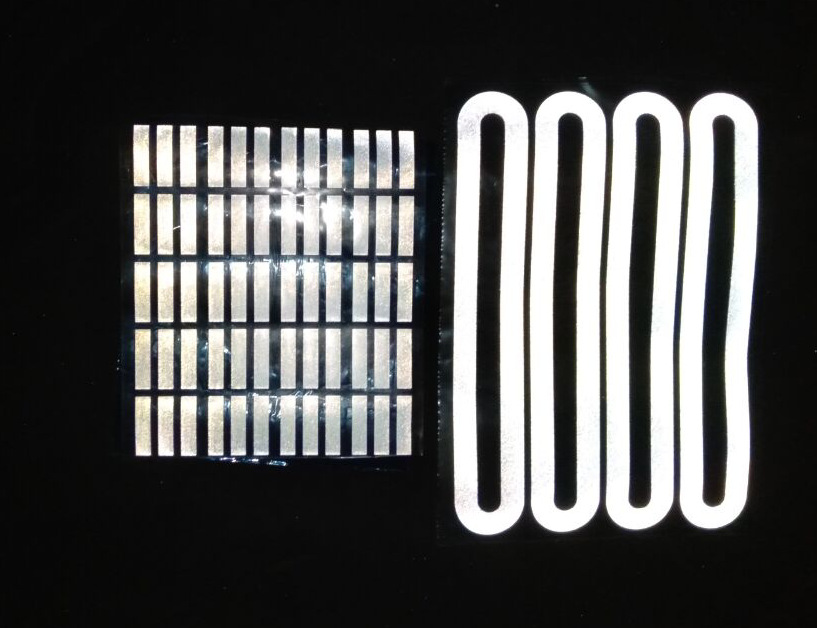

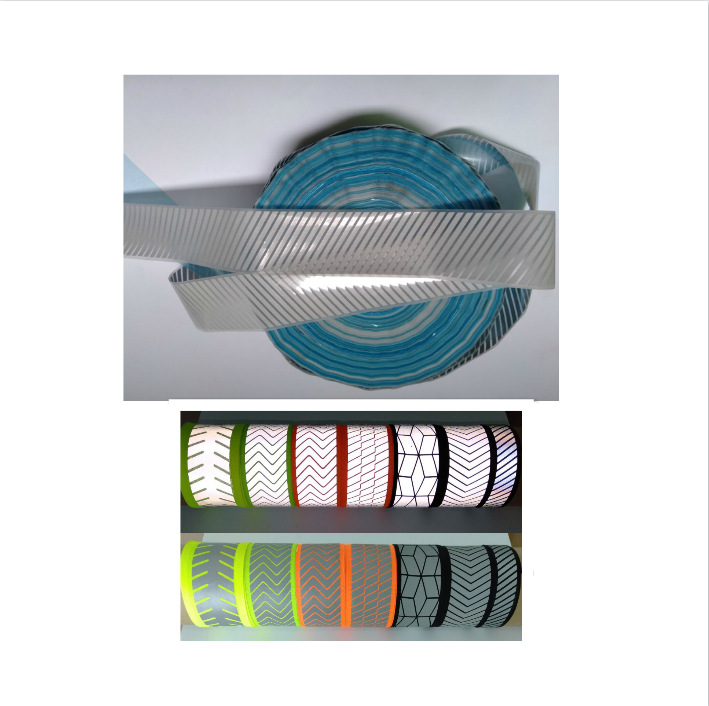

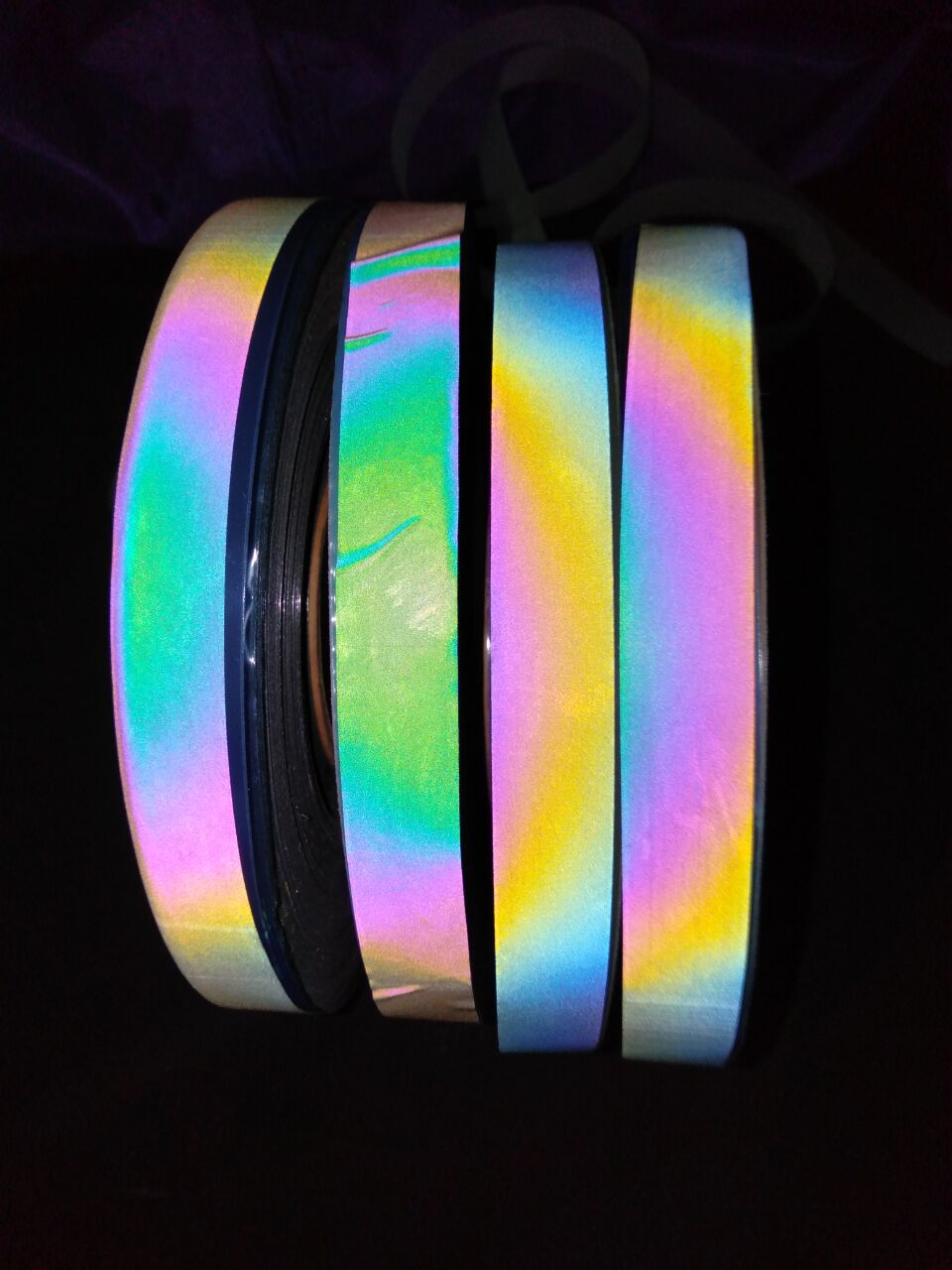

Silver reflective engraving strips, silver reflective cutting strips, colors and patterns can be custom-made, and can be cut to the specified specifications and engraved with the customer's requirements. They can be directly heat transferred to clothes and bags.

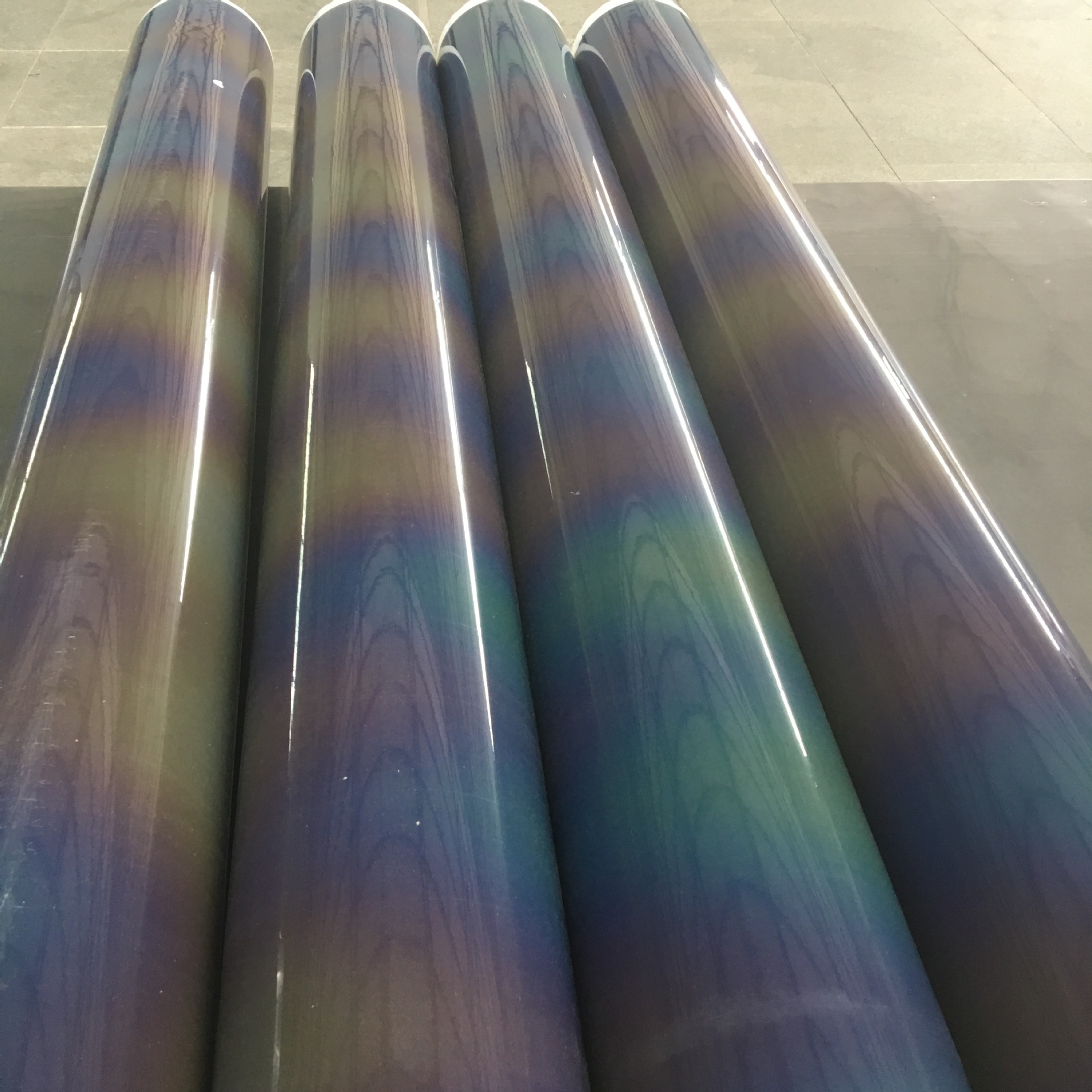

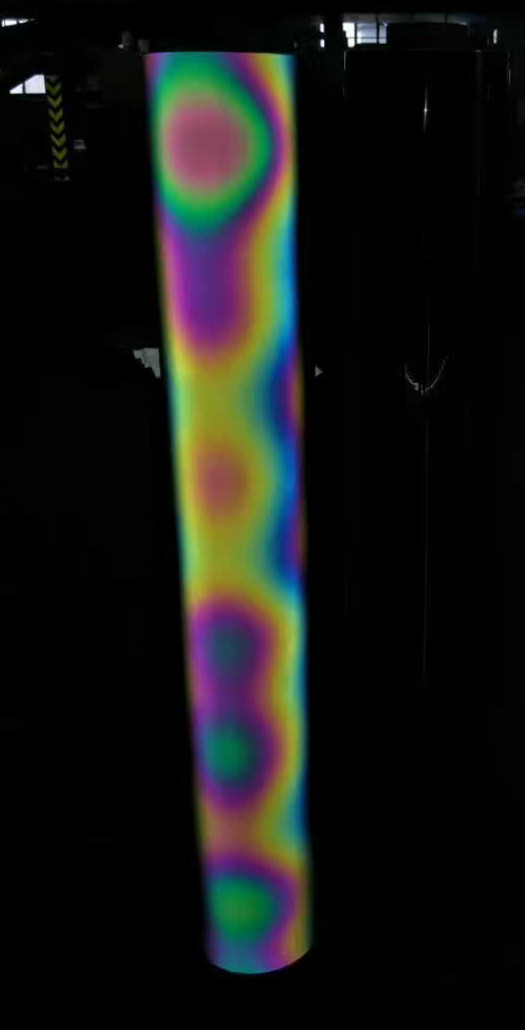

Colorful Carving Heat Transfer Film:

Huan Cai Hot Transfer Reflective Film Strip, can be directly hot transferred to clothes, bags.

Product Performance

1, Reverse-reflectivity coefficient: meets EN20471 Class II standard

2, Washability: Can meet the ISO6330 standard specified by EN471; 2A washability for more than 25 times.

3, Dry-cleanable performance: Can be dry-cleaned more than 5 times according to ISO3175 standards.

4. Environmental requirements: This product does not contain toluene, azodyes, free heavy metals, etc., which meets the ?ko-Tex Standard 100 and the REACH regulations, etc., European environmental standards.

Instructions:

1. Carving:Cut the material to the desired shape using a engraving machine, peel off the adhesive film that is not part of the pattern, and ensure that the cutting depth is between 10 and 30 UM, with a cutting pressure of 160-170GF for optimal results. This will create a reflective silver or colored graphic.

2. Placement: When using, peel off the plastic protective film or the white release paper from the back of the hot transfer film. Place the rough side of the reflective transfer pattern (the side with the design) onto the correct position on the substrate where the pattern is to be applied; the smooth side of the film should face the substrate.

3, Heat: Attach a thin cotton cloth to the heating area of the heat transfer machine and then heat the cotton cloth.

4. Transfer:The heat transfer machine pressure is 5 kilograms. Please ensure that the work surface is level and the temperature of the heat transfer plate is consistent with the displayed temperature. At the same time, it is necessary to check whether the temperature of the heat transfer plate is uniform. The transfer temperature and time should be determined according to the melting point of hot melt adhesive and the fabric. It is usually 150°C and 15 seconds.

5. Peel off the film:After the transfer is completed, the reflective film must be coldly peeled off the PET film. Press the cloth with your hand and tear the film parallel at 180 degrees.

6. Our reflective film inSticky cloth problemAfter much effort, common fabrics (tested 30 types of cloth) do not show adhesive bonding or pressing marks after ironing.

Note:

1, If the fabric has elasticity, it is necessary to preheat the fabric first before performing the above operations.

For customers with high durability requirements: 1. You can increase the pressure and extend the pressing time. 2. After pressing on the front, immediately press on the back for 3-4 seconds or bake it once in the oven, and then cool it before removing the film.

3, If the fabric or filling cannot withstand a pressing temperature of 150 degrees and 15 seconds, it is necessary to reduce the temperature and extend the time to achieve the desired effect.

4, Uncovering: If there is a phenomenon of glue part separation, it may be caused by the heat transfer glue not drying completely. Please continue to bake at low temperature to dry the heat transfer glue. If there are speckles on the reflective surface, you can smooth them with a cloth.

5,24-48 hours later, the durability can be tested. (The quality of durability is mainly related to the glue.)

To avoid damaging the reflective surface layer and creating waste, the material cannot be bent or vertically placed during handling. When rolled, the radius cannot be too small!

For more products, please consult customer service.

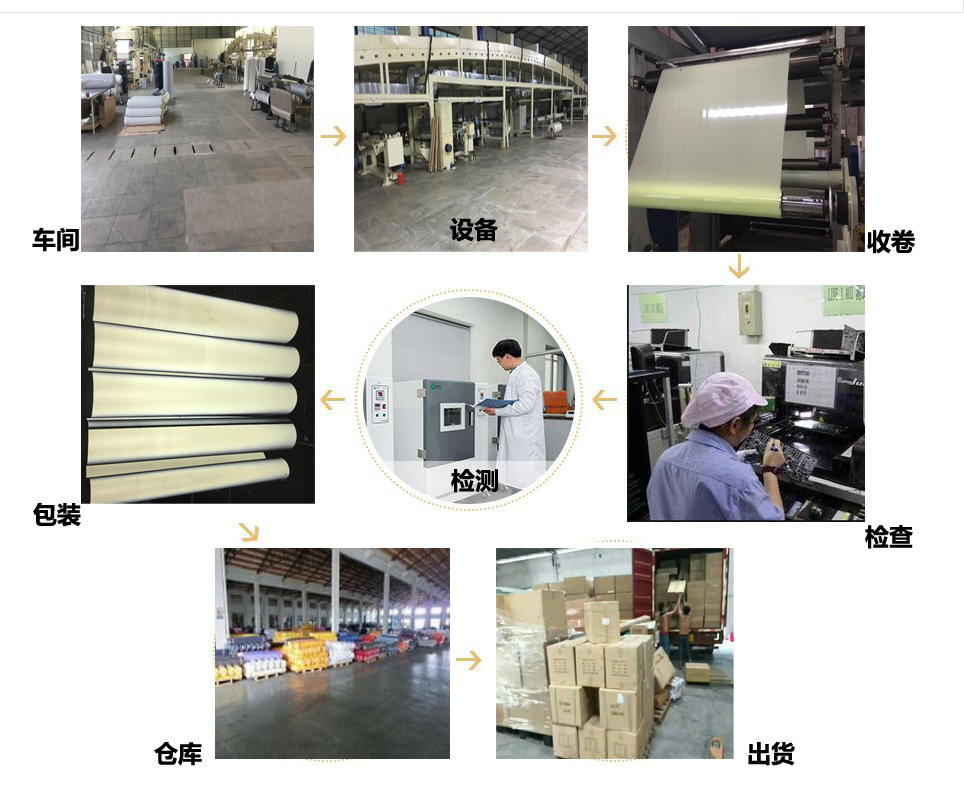

Company Introduction

Company Introduction

Production Reality

Production Scene

CERTIFICATE

Certificate

TANSPORT MODE

Transport Mode

FAQ:

Do you accept small batch orders?

The company's regular reflective fabric products are all in stock, and can be ordered in small quantities. They can also be cut to the specifications required by customers as needed.

How long is the lead time for the reflective fabric?

The lead time for our regular inventory products is approximately 2-3 days. For specific information, please consult our customer service.

3. Can samples be provided free of charge?

The company can provide free sample shipping. Please contact customer service for specific arrangements.

4. Can custom specifications of reflective fabric be provided?

Customized to customer requirements in various specifications.

Can different base fabrics, brightness, or color requirements for reflective fabric be customized?

Yes, the factory can produce a sample based on the customer's specific requirements for the base fabric, brightness, and color, and then produce the bulk order. Please consult the customer service for more details.

What are the categories of reflective fabric usually?

Reflective fabric can be generally classified into synthetic fibers, TC (polyester-cotton), flame-retardant, or elastic reflective fabric, depending on the base fabric. Further, they can be divided into standard brightness and color, such as 'general brightness' and 'color.'

Highlight or bright silver reflective fabric.

What is the international standard for reflective Buos in the United States? What are the specific requirements?

Reflective fabric is labeled as EN ISO 20471:2013, and the American standard is ANSI/ISEA 107:2015. The detection needs to meet the brightness requirements at 16 angles.

The brightness of 5°12′ is greater than 330 (cd/lx.m2). The product can withstand more than 25 washes and passes a series of tests including friction, bending, low-temperature folding, temperature difference, and rain exposure.

Wait for the exposure test.

Is reflective fabric environmentally friendly and safe? What are the standards?

Our company's reflective fabric products have passed the international textile green environmental protection standard Oeko-Tex 100 certification and are regularly updated annually to ensure the safety and environmental protection of the products.

Inquiry Introduction:

Due to the large fluctuations in raw materials, coupled with the competitive pricing of competitors on the internet, we are unable to provide accurate pricing for each product. We can only offer a reference price. If you are very interested in our products, please contact me on Alibaba Messenger. I will offer you a quote based on your requirements at the first opportunity.

Update time:

TOP