Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| mixed batch | CN¥ 0.0 |

HaoDong daily-use commodity factory 15yr.

Contacts:alena Chat

Mobile:86-13957901711

E-mail:31472981@qq.com

Kaufert's Invisible Glass Glue Classification:

Kaft-O-Speed: for bonding glass to glass, glass to iron, and crystal glass products, etc.

K-300 Invisible Glue: Large areas of glass, crystal, etc.

K-302 Invisible Glue: Special for glass coffee tables, glass to metal, etc.

K-303 Invisible Glue: Acrylic Plastic, PMMA Plastic, Plastic and Glass, etc.

K-3181 Invisible Glue: The King of Plastics, ABS, PVC, Organic Glass, Fish Tanks, etc.

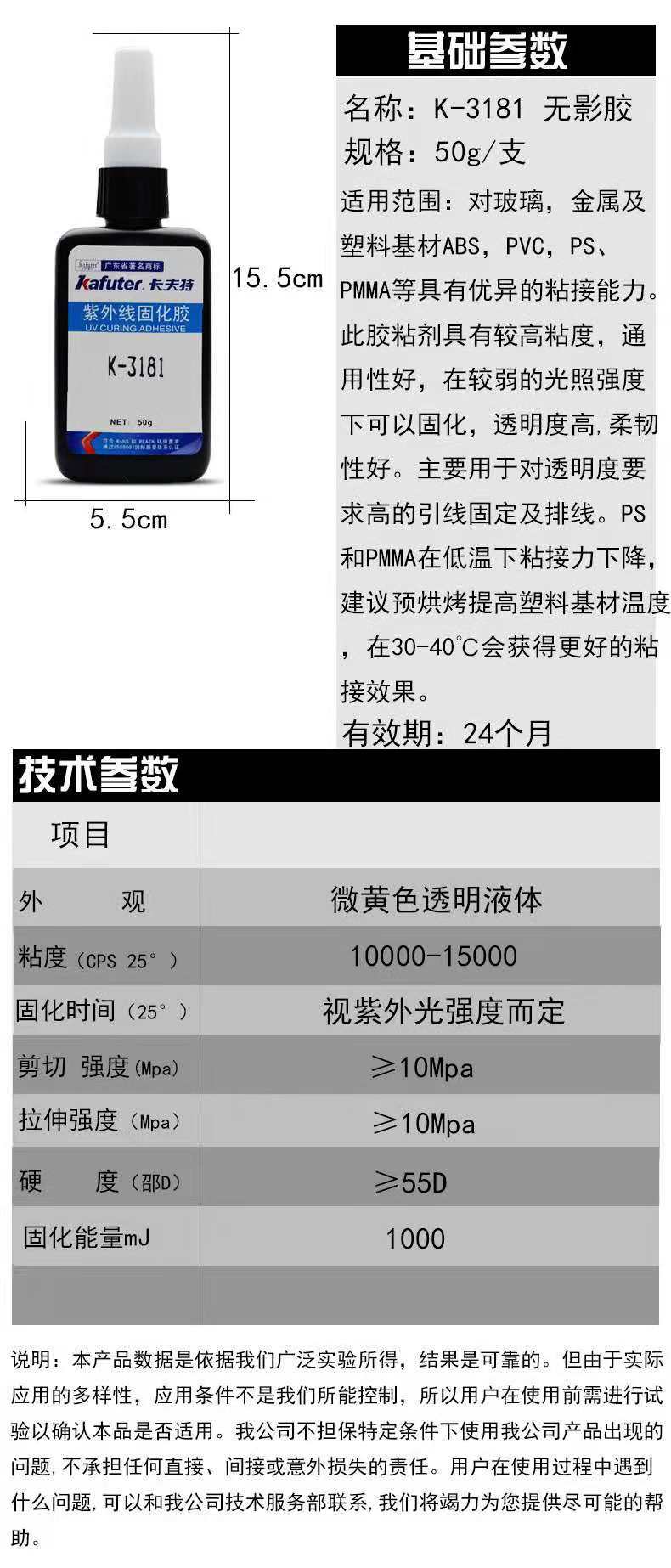

Product Name: K-3181 Invisible Glue

K-3181 invisible glue from Kaffte is a highly versatile and extremely strong invisible glue with a bonding strength that is four times that of ordinary invisible glue. It has excellent flexibility and can not only bond glass and metal but also transparent soft plastics such as PVC/ABS/PC/acrylic!

K-3181 adhesive from Carfex has a high viscosity, does not absorb water, and is very suitable for bonding fish tanks and glass display cabinets.

Packing Specification: 50g/piece 80 pieces/box

Note: UV glue must be cured under ultraviolet light or sunlight to harden, and ordinary household lighting cannot harden it. The curing time is 1-10 minutes.

Typical curing properties:

K-3181 cures under ultraviolet light, and also slowly cures in sunlight. A light source with a wavelength of 220-260nm is beneficial for surface curing. The curing rate, depth, and initial dry effect are related to the ultraviolet light source, illumination time, and the material's light transmission rate. It is recommended to determine the curing process through experiments.

Curing time: 90s - Curing energy 400mJ - 125W Philips high-pressure fluorescent lamp, 4.5 mW/cm2 UVA

Curing Time: 180s - Curing Energy About 1000mJ, 125W Philips High-Pressure Fluorescent Lamp, 4.5 mW/cm2 UVA

Typical post-curing performance:

Tensile shear strength (GB 7124-86) - Lapped area 25×12.5 = 312.5 mm2: Glass/Stainless steel, ≥8 MPa at 30℃

Instructions:

Clean the adhesive surface, remove dust, oil, and dry it before applying the adhesive. Determine the amount of adhesive to be applied based on the needs.

Recommended minimum light intensity: 70 mW/cm²

Materials that are temperature-sensitive, such as thermoplastic materials, require a cooling device.

Check the curing of plastic materials to prevent stress cracking caused by liquid.

Excess glue can be wiped off.

Do not pour the remaining glue back into the original packaging to prevent contamination.

Notes:

Avoid contact with eyes, skin, and clothing. This product may cause mild irritation to eyes and skin. If it accidentally gets into the eyes, immediately flush with large amounts of water and seek medical attention if discomfort persists. Wash skin with soapy water after contact. After contact with clothing, wash thoroughly before wearing. Keep children away from this product.

Storage: This product is sensitive to light and heat, and needs to be stored in a cool and dry place, away from direct sunlight.

Update time:

TOP