Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| mixed batch | CN¥ 0.0 |

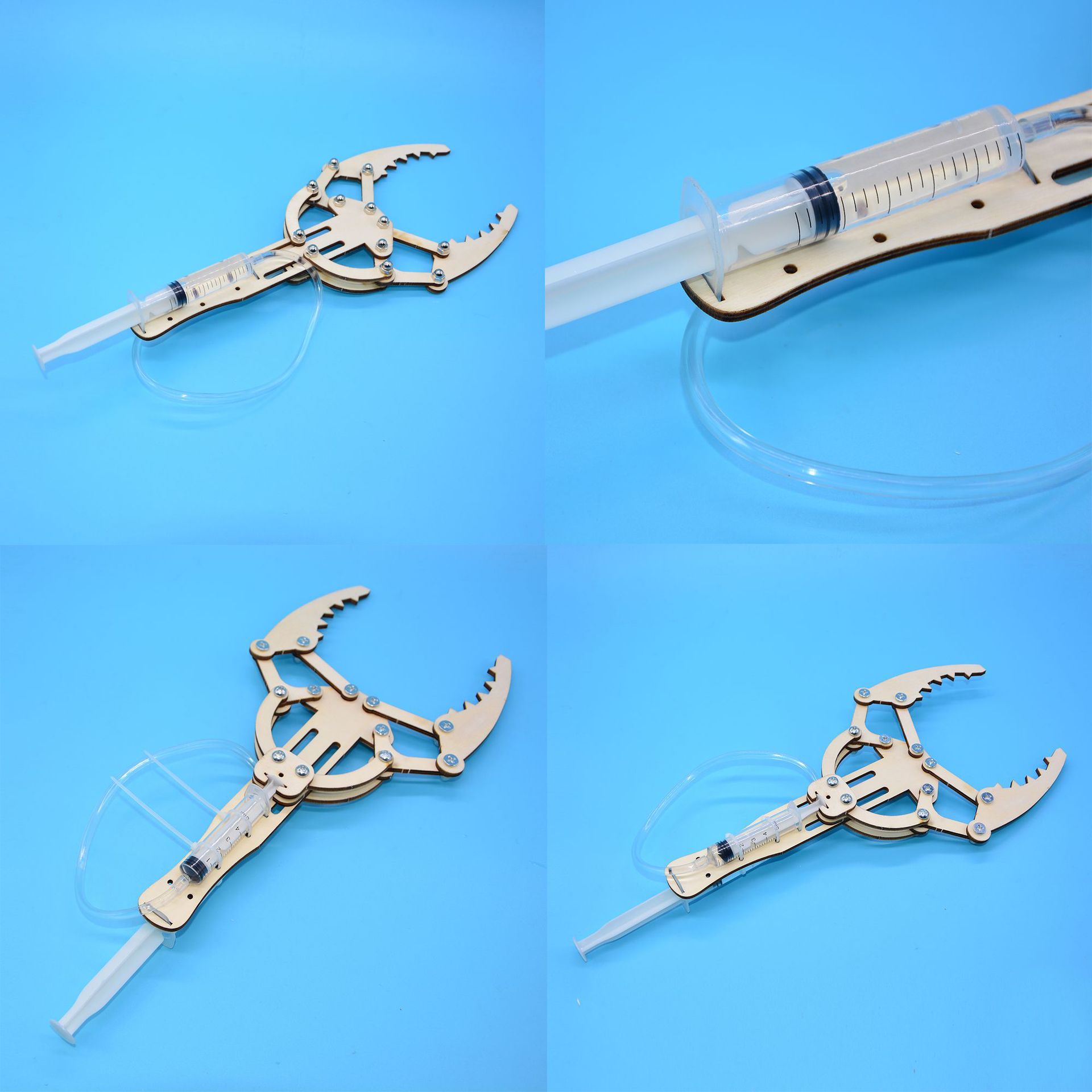

Product Name: Hydraulic Robot Arm

Article number: KX1913 Hydraulic Robot

Size: 360*150*40mm

Weight: About 150g

Material: Wood + Metal Hardware + Syringe + Hose + Twine...

Packing: 350pcs

Box Specification: 600*550*450mm

Understanding the components of a simple robotic arm and the principles of design involved

The hydraulic mechanical arm is a carefully constructed model of a mechanical arm made from wood and universal toy components, making it a great brain-teasing toy for practicing hands-on skills. After assembly, it can simulate the operation of a human arm. The structure is clever, the movements are smooth, and the design has a mechanical feel, making it easier to understand the principles of these automated mechanical devices! Come and join us to become a tech-savvy kid!

Scientific Principles

Hydraulic robotic arms utilize the principles of Pascal's law. Pascal's law is a principle of hydrostatics, which states that in a compact and static fluid, any point under external force will experience an instantaneous increase in pressure. This pressure increase is transmitted instantaneously to all points in the static fluid. According to Pascal's law, if there are two pistons of different sizes in a fluid system, the pressure on both pistons will be equal. The pressure is equal to the applied force divided by the area of the force. If a small push is applied to the small piston, the pressure will be transmitted through the fluid, and a larger force will be generated on the larger piston. This hydraulic robotic arm controls the sliding of the second syringe by pushing and pulling the first syringe, and then controls the opening and closing of the grasping device through a set of mechanical structures.

Scientific Extension

In the face of the ever-increasing development of technology, the main difference between robotic arms and human arms lies in their flexibility and durability. The major advantage of robotic arms is that they can repeat the same action without fatigue, as long as the machinery is functioning normally! The application of robotic arms is becoming increasingly widespread. It is an important branch of industrial robotic arms that have developed over the past few decades and have the ability to perform tasks accurately.

The robot arms can be classified by driving methods into hydraulic, pneumatic, electric, and mechanical. The characteristics are that they can perform various expected tasks through programming, and they combine the advantages of both human and mechanical hands in construction and performance.

A machine hand, also known as a robotic hand or robotic arm, is an automated device that can mimic certain movements of the human hand and arm to perform tasks such as grasping, moving, or operating tools according to a fixed program. It is composed of three main parts: the actuator, the driving mechanism, and the control system. The machine hand can replace heavy labor to achieve mechanical and automatic production, operate in hazardous environments to protect personal safety, and is widely used in industries such as mechanical manufacturing, metallurgy, electronics, light industry, and nuclear energy.

In today's life, under the progress of technology, the main difference between robotic arms and human arms is flexibility and durability. That is, the great advantage of mechanical hands is that they can repeat the same action without feeling tired under normal mechanical conditions! The application of mechanical arms will become more and more widespread. Mechanical arms are a branch of a high-tech automatic production equipment that has developed over the past few decades. They are important for the accuracy of the work and the ability to complete the task in the environment.

Types, which can be classified by driving methods into hydraulic, pneumatic, electric, and mechanical. The feature is that they can be completed through programming.

Performing various expected tasks, combining the advantages of human intelligence with the precision and efficiency of mechanical devices.

It developed on the basis of early ancient robots that appeared, and the research on mechanical hands began in the mid-20th century. With the development of computers and automation technology, especially since the advent of the first digital electronic computer in 1946, computers have made remarkable progress, moving towards high speed, large capacity, and low cost. At the same time, the urgent demand for mass production has promoted the progress of automation technology, which has laid the foundation for the development of robots. On the other hand, the research on nuclear technology requires certain operating machinery to replace humans in handling radioactive substances. In this context of demand, the United States developed a remote-controlled mechanical hand in 1947 and a mechanical master-slave mechanical hand in 1948.

The robot arm was first developed in the United States, with the Unimation Corporation introducing the first robot arm in 1958. Its structure consists of a rotating arm mounted on the body, a grasping mechanism at the top equipped with electromagnetic blocks, and a teaching-type control system. With the rapid development of computer and automatic control technology, agricultural machinery is entering an era of high automation and intelligence. The application of robotic arms can improve labor productivity and product quality, improve working conditions, and solve issues such as labor shortage.

The robot arm is mainly composed of three main parts: the actuator, the driving mechanism, and the control system. The hand is the part used to grasp the workpiece (or tool), and there are various structural forms depending on the shape, size, weight, material, and operational requirements of the grasped object, such as clamping type, holding type, and adsorption type. The motion mechanism enables the hand to complete various rotational (swing), moving, or composite movements to achieve the prescribed actions, changing the position and posture of the grasped object. The independent movement ways of the motion mechanism, such as elevation, extension, and rotation, are called the degrees of freedom of the robot arm. In order to grasp objects at any position and orientation in space, it needs to have 6 degrees of freedom. The degree of freedom is a key parameter for the design of the robot arm. The more degrees of freedom, the greater the flexibility and the wider the applicability of the robot arm, and the more complex its structure. General specialized robot arms have 2-3 degrees of freedom. The control system is to complete specific actions by controlling the motor of each degree of freedom of the robot arm. At the same time, it receives feedback information from the sensor to form a stable closed-loop control. The core of the control system is usually composed of microcontrollers or DSP microcontroller chips, which realize the desired functions through programming.

With the development of network skills, the problem of network operation for robotic arms is also a direction for future development. Industrial robotic arms are a high-tech automated production equipment that has developed over the past few decades. Industrial robotic arms are an important branch of industrial robots. Its characteristic is that it can complete various expected task operations through programming, combining the advantages of both humans and machines in structure and performance, especially reflecting the intelligence and adaptability of humans. The accuracy of robotic arm operations and the ability to complete tasks in various environments have a broad development prospect in various fields of the national economy.

The robot arm is a new type of device that has developed in the process of mechanical and automated production. In modern production processes, robot arms are widely used in automatic production lines, and the research and production of robot arms have become a rapidly emerging technology in the field of high technology, which has further promoted the development of robot arms, making robot arms better achieve the organic combination with mechanical and automation. Although robot arms are not as flexible as human hands, they have the characteristics of being able to continuously repeat work and labor, not tired, not afraid of danger, and the strength of grasping and lifting heavy objects is greater than that of human hands, so robot arms have received attention from many departments and are becoming more and more widely applied. China's plastic machinery has become one of the fastest-developing industries in the mechanical manufacturing industry, with an increasing annual demand. The high-speed development of China's plastic machinery industry is mainly due to the following two major factors: one is the equipment update and the elimination of outdated equipment due to the demand for high-tech equipment; the other is the high-speed development of the domestic plastic processing industry, which has a strong demand for plastic machinery.

Industrial manufacturing field:

The main purpose of robots in the mechanical manufacturing industry is to replace humans to complete mass production and high-quality work, such as the manufacturing of automobiles, ships, and certain household appliances (televisions, refrigerators, and washing machines). In the automation production lines of industries such as chemical engineering, robots are used for spot welding, arc welding, spray painting, cutting, electronic assembly, and the handling and packaging of the logistics system.

Military field:

Mainly to let the robot perform some automatic reconnaissance and control tasks, especially some relatively dangerous tasks, such as, unmanned drones, bomb disposal robots and mine clearing robots. The robot can also replace soldiers to complete those less complex engineering and logistics tasks, so that the soldiers can be relieved from heavy work and engage in more important tasks.

Entertainment field:

Update time:

TOP