Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

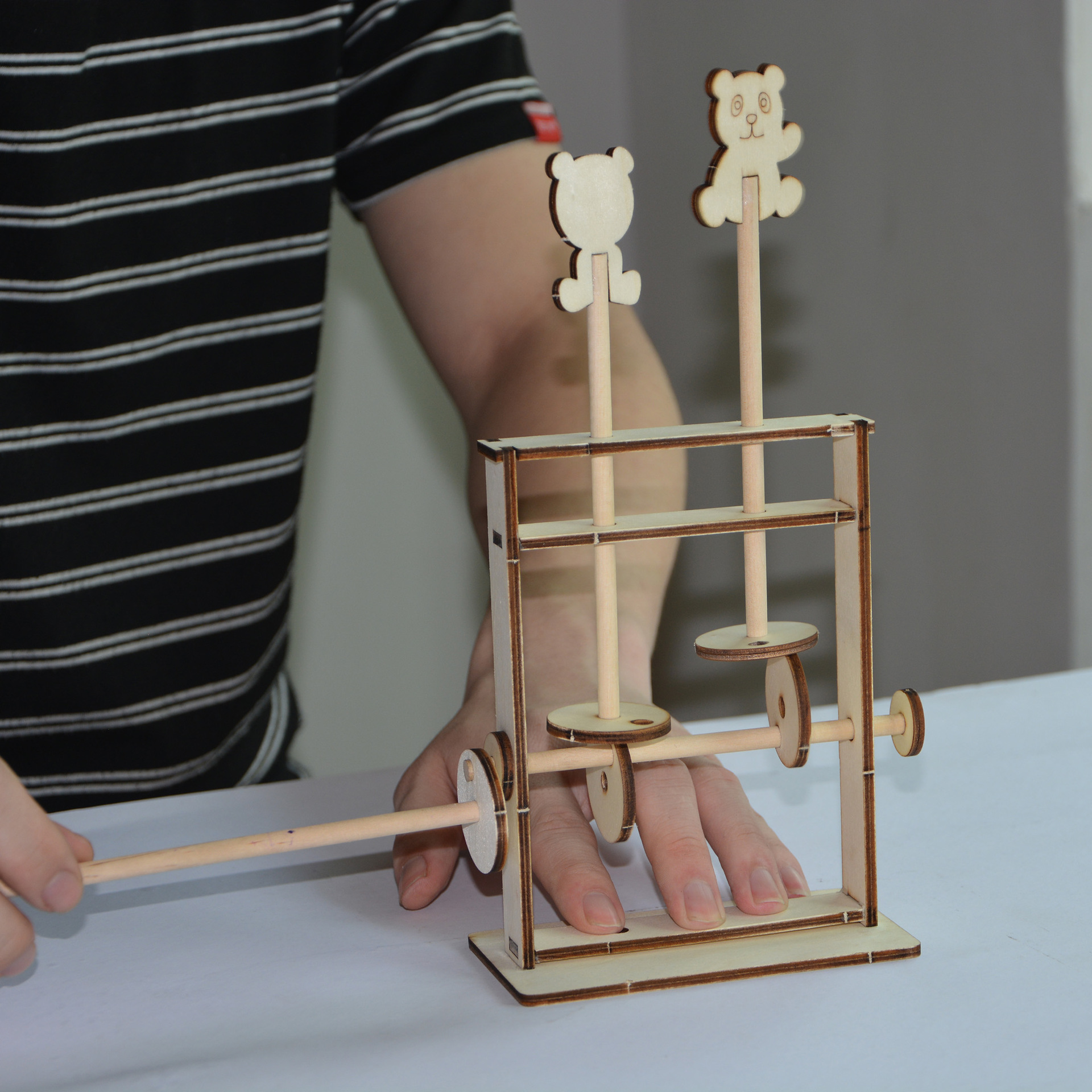

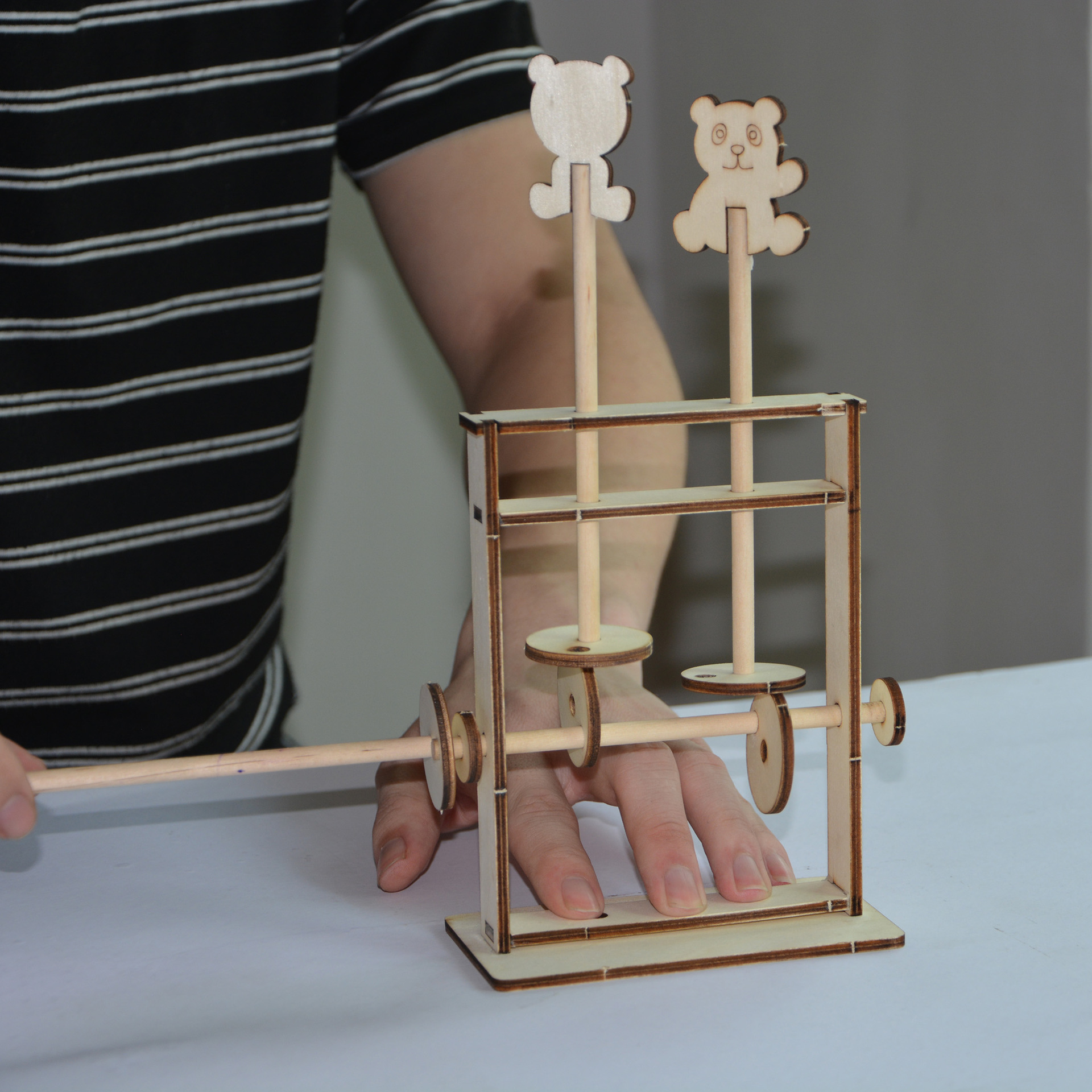

| kx841 wooden double dance | CN¥ 0.0 |

Product Name: Wooden Duo Dance

Product Code: KX841

Size: 170*65*250MM

Packing: Packing Bag

Packing: 300PCS

Box Specification: 60*45*55 CM

Wooden Duo Dance Principle

A cam mechanism is a high-leverage mechanism composed of three basic components: a cam, a follower, and a frame. The cam is a component with a curved profile or a groove and is typically the driving member, moving either uniformly at a constant speed or in a recursive linear motion.

A mechanism driven by the rotary or reciprocating motion of a cam to make the actuated member move or swing in a prescribed manner. The cam has a curved profile or groove, including disc cam, cylinder cam, and sliding cam, among which the cylinder cam's groove curve is a spatial curve, thus belonging to a spatial cam. The actuated member makes point or line contact with the cam, including roller actuated member, flat bottom actuated member, and actuated member, etc. The actuated member can maintain contact with any complex cam profile, enabling any movement, but it is prone to wear and is suitable for low-speed mechanisms with small force transmission. To ensure that the actuated member maintains contact with the cam, spring or additional force can be applied. A cam with a groove can make the actuated member transmit a determined motion, which is a type of definite motion cam. In general, the cam is the active element, but there are also passive or fixed cams. Most cams have a single degree of freedom, but there are also double-degree-of-freedom split cone cams. Cam mechanisms are compact in structure and are suitable for applications requiring the actuated member to make intermittent movements. Compared with similar mechanisms in hydraulic and pneumatic, cam mechanisms have reliable movement, which is why they are widely used in automatic machines, internal combustion engines, printing machines, and textile machines. However, cam mechanisms are prone to wear and have noise. The design of high-speed cams is quite complex, and they require high manufacturing standards.

Working Principle:

It bears the force transmitted by the connecting rod and converts it into torque to output through the crankshaft, driving other attachments on the engine to work. The crankshaft is subjected to the combined effects of centrifugal forces from the rotating mass, periodic changes in gas inertia forces, and recoil inertia forces, making the crankshaft bear the action of bending and torsional loads.

Experiment Report:

The structure is simple, compact, and convenient to design, so it is widely used in machine tools, textile machinery, light industry machinery, printing machinery, and the integration of mechanical and electrical equipment assembly. As long as an appropriate cam profile is made, the driven rod can obtain any predetermined motion law.

Update time:

TOP