Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| mixed batch | CN¥ 0.0 |

Pujiang Bochang New Material Technology Co., Ltd 15yr.

Contacts:Kuangqunhua Chat

Mobile:86-15657905600

E-mail:138552828@qq.com

Product Introduction

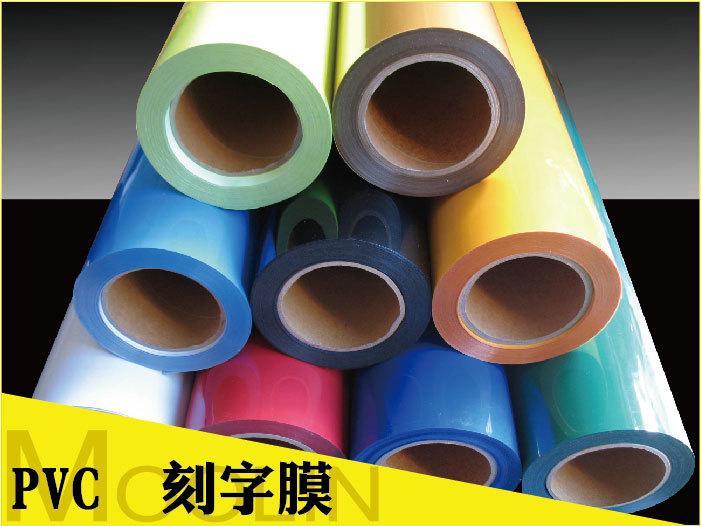

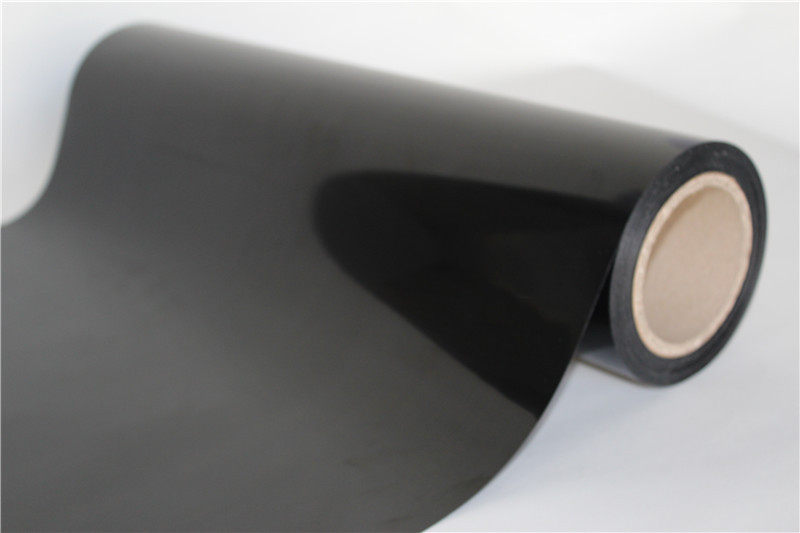

Hot transfer engraving film has a soft feel. This product must be used with a computer engraving machine and heat transfer machine, which is very convenient. It can also be used for multi-color transfer, which can increase the richness and variability of the product. Moreover, it is not limited by the fabric.

Wash-resistant, non-fading, and well-adhered, this product is widely used in monochrome graphics, clothing, textiles, and paper crafts.

Normal specification; 61cm diameter per circle, 50m per roll. We have a variety of colors in stock, and we can also customize different specifications and colors according to customer requirements.

Instruction Manual

1. Carve the required graphics with a computer engraving machine, and peel off the adhesive film outside the pattern.

2, directly transfer the hot-stamped image onto the substrate using a hot stamping machine.

3, the transfer tumbling temperature is generally between 150-180°C, the time is 10-15 seconds, and the pressure is 20-30 pounds [according to different materials and requirements].

4, this product can be hot-peeled or cold-peeled, just peel off the surface film.

III. Usage Instructions:

1. Use a computerized engraving machine to cut the material into the desired shape, then peel off the adhesive film that is not part of the pattern. The cutting depth should be between 10 and 30 UM to ensure that the cut penetrates the underlying film.

2. Peel off the protective film (or you can also tear it off first), and then use a heat transfer machine to directly transfer it onto the substrate.

3. The transfer tumbling temperature is generally between 150-180°C, with a time of 10-20 seconds, and the pressure is 20-30 pounds (determined according to the material and requirements).

4. After the product cools, peel off the surface film.

Update time:

TOP