Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

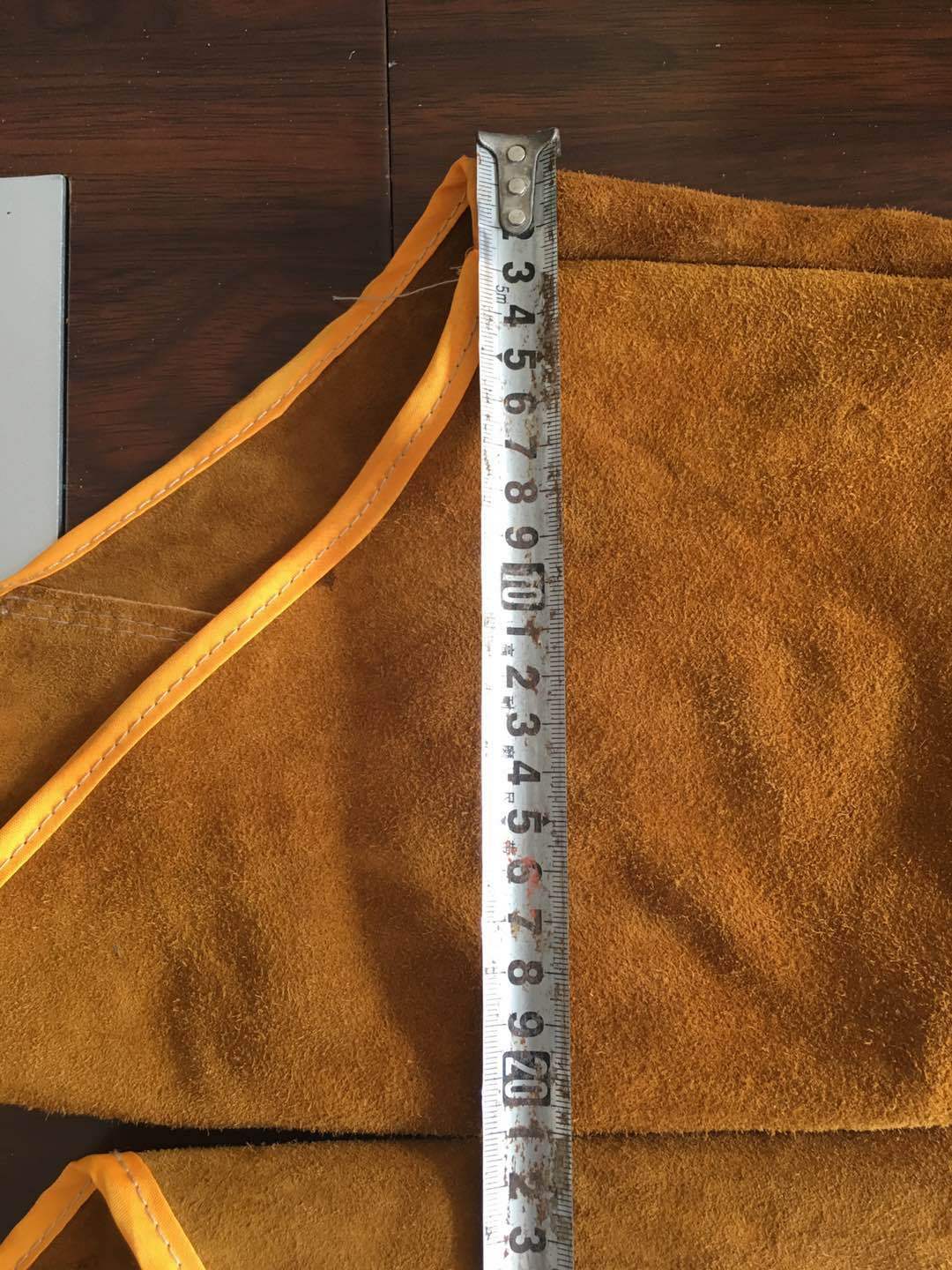

| yellow 58cm: free size | CN¥ 14.9 |

| yellow 55cm: free size | CN¥ 13.5 |

Yiwu Tianqiao Gloves Factory 15yr.

Contacts:Barry Zhu Chat

Mobile:86-18458080606

E-mail:463673005@qq.com

Welding gloves are a type of work gloves used by welding workers for protection and comfort. They are suitable for cutting, welding, and moving.

For transportation and other purposes.

Chinese name

Welding gloves

解释

A type of welding worker's work gloves

用途

Suitable for cutting, welding, and moving, etc.

特点

Resistant to wear, resistant to knife cutting, resistant to tearing, etc.

Standard function

Anti-moisture, anti-wear, anti-knife cut, anti-tear, anti-pierce, anti-oil, anti-combustion, anti-heat conduction, anti-hot air flow, anti-fine gold

Belongs to slag.

Welding gloves are classified as electrical welding safety equipment.

其作作用

1: Prevent Electric Shock. During the welding process, the welding gloves serve as a protective measure for the welder to prevent electric shock. For example, with the hand arc welding machine, the empty load voltage is generally between 50V and 90V. Compared to the 36V AC safe voltage, the welding machine's empty load voltage poses a risk to the welder.

The gloves of welders are also classified as dangerous voltage. Therefore, the gloves must meet the safety voltage resistance of 3000V.

2: Preventing Burn and Scalding. Except for tungsten inert gas (TIG) welding, which has no spatter, other welding types have spatter that could potentially harm the welding operator.

Workers may suffer from burns and scalding injuries to their hands and wrists. Welding gloves are made of sheepskin leather, effectively isolating welding splatters.

Burns and scalding of the hands and wrists of welding operators. In addition, welding arc light is a harmful light radiation source, and gloves can also be used.

Effectively isolate harmful light radiation to the hands and wrists.

Material

Outer layer: cow leather, cow leather, pig skin, sheep skin and other natural leathers. Inner layer: thickened inner, cotton inner, cotton inner, denim inner and various inner layers.

Features

Mainly for wear resistance, anti-cutting, with fire resistance and insulation performance, blocking radiation, while also having a certain insulation performance.

Main Types

The impact on welders may vary depending on the different types of welding.Therefore, according to various types of welding, there are roughly two categories of electric welding gloves:

Argon arc welding gloves (TIG) have less welding splatter, but they are hot, have strong radiation, and the wire is relatively thin. Therefore, these gloves are designed to protect the hands from these hazards.

The feel is quite good, quite thin, and not too long.

So-called manual welding gloves are those we often see where a pair of pliers holds the welding rod. This type of welding

High-temperature spatter is common. Therefore, the gloves used are mostly double-layered with a length of over 34CM.

Notes

Here are some points to note when using gloves:

1. Select the appropriate gloves for different work environments according to the above table. The size of the gloves should be appropriate. If the gloves are too tight, they restrict blood circulation, which can cause fatigue and discomfort; if they are too loose, they are not flexible to use and are easy to fall off.

2. The gloves selected should have sufficient protective effects. For example, in an environment where steel-wire anti-slash gloves are used, it is not suitable to choose synthetic gloves.

Anti-slash gloves made of yarn, etc. To ensure their protective function, it is necessary to replace the gloves regularly. If the use period is exceeded, there may be

To cause harm to the hands or skin.

3. Check the gloves at any time, looking for any small holes or damage, especially in the fingers. For gloves with welding, you can check for any wear or damage around the fingers and the wrist area.

To conduct the inspection using the inflatable method.

4. Pay attention to the use of gloves in different occasions. If a pair of gloves is used in different places, it may significantly reduce the service life of the gloves.

5. Use with caution, do not throw away contaminated gloves at will to avoid causing harm to others. For gloves that are not in use for the time being,

The set should be placed in a safe place.

Update time:

TOP