Product Description

Resin zipper, also called as molded zipper, normal size has No. 3-10, made of POM with injection molding process.

Because of its light weight, bright colors, good touch feeling, it was well used for jackets, children's clothing, ski suits, luggage products, etc. uniforms, down jackets, ski suits, luggage, etc.

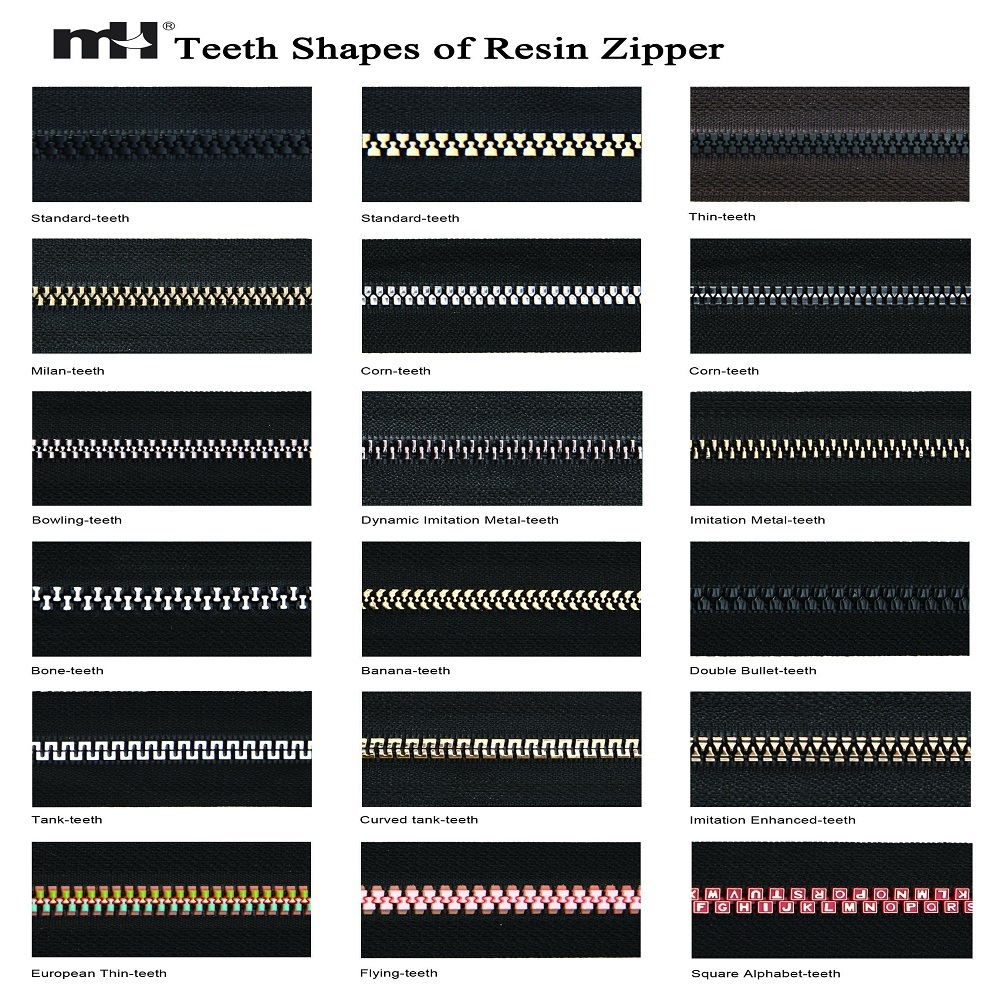

MH resin zipper has bright color, excellent color fastness, which is not easy to fade. The teeth have different shapes, beautiful, and fashionable, it is the first choice of the fashion trends.

MH resin zipper teeth is made of PP material, with lower cost comparing with resin zipper, mainly used for down jackets, jackets, overalls, school uniforms, etc.

MH resin zipper has advantages of

Eco-friendly, azo-free dyeing, various colors, accurate color matching, high color fastness

Lead-free and nickel-free slider

Flat tape, thick and soft

High strength teeth

Zipping smoothly, good touch feeling

Standard and stong packaging, and the product can be well protected

Fast delivery, high production capacity with guaranteed quality

Oeko Tex Standard 100 Annex 6 Class 1 certificate

Having 3C color card with 600 colors, and MH zipper catalogue

Professional service team with quick response

Factory & Packaging

Certificate

MH has certificates of ISO 9001:2015, ISO 14001:2015, ISO 45001:2018.

About MH

Ningbo MH was established in 1999, specialized in garment accessories and tailoring materials. After years of development, MH has set up business relationship with more than 150 countries, with sales amount $471 million. The main products are sewing thread, embroidery thread, ribbon & tape, embroidery lace, button, zipper, interlining, and other accessories & fabrics.

At present, MH owns nine factories located in 3 industry zones, with 382,000m2 plant area and 1900 workers.