Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| DHG9420A | CN¥ 3942.5 |

| DHG9620A | CN¥ 9025.0 |

| DHG9920A | CN¥ 13300.0 |

| DHG9030A | CN¥ 1662.5 |

| DHG9140A | CN¥ 2517.5 |

| DHG9240A | CN¥ 3277.5 |

| DHG9070A | CN¥ 2042.5 |

Performance Features

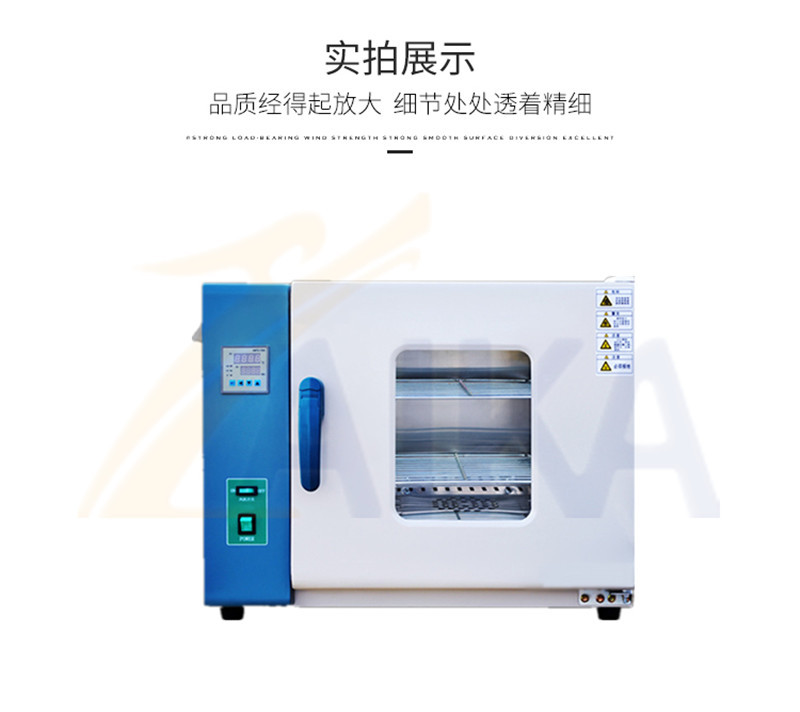

◆Adopting the innovative streamlined and curved design, the casing is manufactured from cold-rolled steel plates and electrostatically sprayed with plastic.

The temperature control system of this machine employs microcomputer single-chip technology, with temperature control, timing, and over-temperature alarm functions.

Reasonable air duct and circulation system ensure a small change in temperature uniformity in the workshop.

◆ Displayed as a high-brightness dual-screen digital tube, the reading is accurate and intuitive, with superior performance and touch-sensitive buttons for setting and adjusting parameters.

The temperature control sensor uses original imported capacitive components.

◆With a timer and stopwatch function.

◆The inner lining is made of polished stainless steel; the semi-circular corners are easy to clean;

The shelf in the workroom can be adjusted to any height and the number of shelves as required by the user.

◆The use of motors and blades for micro-air circulation allows users to eliminate concerns about the dispersal of small or powdery items during cultivation.

The box door is equipped with large-angle insulating tempered glass for easy user observation, and the use of nano-material door seals and insulation materials makes the overall performance of the machine even more superior.

Instruction Manual

1. The box is placed on a dry floor and work surface inside, and the CO2 incubator does not need any other fixed devices.

2. A circuit breaker or air switch should be installed in the power supply line for this box exclusively, and a grounding wire with a cross-section area one times larger than the power cable should be used.

3. Before powering on, check the electrical performance of this box and pay attention to whether there is a short circuit or leakage.

4. Prepare the sample and place it in the chamber. Close the door. If necessary, dry the chamber by opening the exhaust valve slightly, leaving a gap of about 10mm.

5. Hydraulic incubator, constant temperature water bath, connect distilled water or deionized water to the inlet, add water until it reaches the overflow outlet.

After Power-on Usage:

6、After connecting the power, you can turn on the heating switch, and the drying chamber will set the temperature dial to the required working temperature. For the water bath shaker, the incubator, and the water-impermeable incubator, set the "set-measure" switch to "set", adjust the temperature setting knob to the required working temperature, and then set the "set-measure" switch to "measure". At this time, the chamber begins to heat up, and the green light will turn on (for smart types or special requirements, please refer to the user manual).

7、When the temperature reaches the required working temperature, adjust to the green light going out, and then make fine adjustments until the green light shines again. This is the constant temperature point where the indicator light alternates between on and off. At this point, you can adjust the knob slightly to make it constant temperature (it is very likely that the temperature will continue to rise due to residual heat, and this phenomenon will take about half an hour to stabilize). When the temperature in the workroom is stable (that is, the so-called "constant temperature state"), you can adjust the temperature controller slightly to improve the accuracy of temperature control. This method can select any working temperature.

8. When the dehydrator is maintained at a constant temperature, the electric heating constant temperature air drying oven should turn off the high-temperature switch and only leave one set of heaters in operation to avoid excessive power consumption, which may affect the accuracy of the constant temperature. When the working temperature is less than 150°C, only one set of heaters should be in operation, and the high-temperature switch should be turned off.

9. Once the temperature has been reached, it can be maintained at a constant temperature for a certain amount of time, as needed by the test (the W-type model can set the constant temperature working time). During this process, the super-constant temperature water bath can be automatically controlled by the temperature controller without the need for manual management.

Update time:

TOP