Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

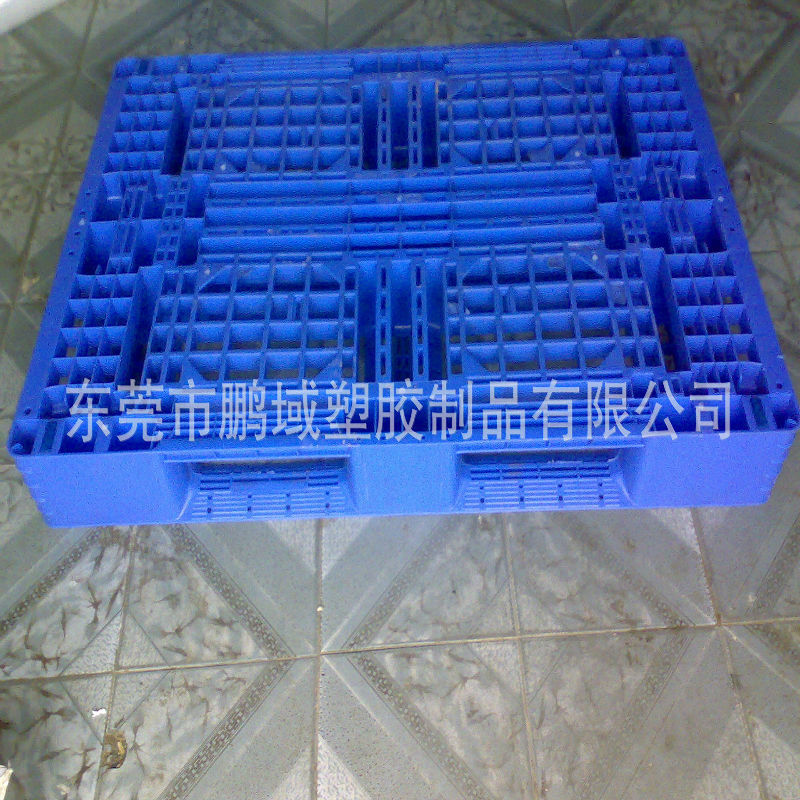

Plastic tray: The difference between new materials and recycled materials

at present, there are many kinds of pallets on the market, and there are many categories of separate plastic pallets. If they are divided from materials, they can be divided into new and recycled plastic pallets, in fact, it is not difficult for everyone to guess the difference between the two, but apart from the difference in materials, is there any difference between the finished tray? Peng Yu company, which has many years of tray experience, let's introduce the difference between the two and how the plastic tray is priced.

New material plastic tray: not only refers to the newly produced plastic tray, but also refers to the plastic tray produced from pure raw materials (no feeding).

1, the simple way to distinguish is that the color is beautiful, and the good gloss is produced by pure raw materials, while the plastic tray mixed with recycled materials is dim and dull.

2, plastic tray price, let's give an example:10kg one tray, raw material price11kg, then feed stock cost is110.00 then the processing fee for this tray will not be lower14.00, in this way, it is very clear, what price should this tray be? If the price is low, then there must be something wrong with the raw material you use.

The pricing standard of plastic pallets: the bearing capacity, self-weight, manufacturing process and after-sales service of plastic pallets are determined.

1, bearing capacity: very well understood, that is, the technical parameters that the tray can. Generally, when we ask customers about the dynamic load (static load is basically no problem), the dynamic load of a product is500kg 1000kg 1500kg 2000kg, their prices are very different.

2, self-weight is the raw material required by the plastic tray, which is the main one. The simple method is to ask how much the tray itself is, and the basic price is also very simple.

3. The manufacturing process mainly requires the mold, whether it is of high fineness, whether the mold cost is high, and there are some later improvements, whether there are anti-slide block, whether there are anti-slip bar, etc.

4, product brand, specific to the value of the industry brand is, whether the production process is mature, fine, whether the product performance is stable, the credibility of the manufacturer, the value of after-sales service of the product

5. Market availability, whether it is a conventional product in the market, and whether there are many suppliers that can provide it.

Our company mainly produces PE plastic tray, large quantity can also be made pp but there is a certain change in price, there is a need pp please contact the seller to confirm the price

comparison between plastic tray and wooden tray

comparison of Two tray functions | plastic tray | wooden tray |

i. Durability | long service life,5-8 year, acid alkali resistance impact resistance | half to one year, it is easy to be eroded after absorbing water and being damp |

II. Reliability | easy to handle and operate, light and strong, low loss and non-slip without maintenance | since it is significant, plus-sized the logistics cost, and there are hidden dangers in leaking nails and burrs. |

III. Sex | special industries, such as food and medicine, are available in appearance color and customized logo. | Limited scope of use, single appearance |

IV. Sex | it can be recycled after being scrapped to reduce garbage disposal costs. | One-time use, can not be recycled, increase the loss of trees |

v. Trend | many new standards on the issue stipulate the use of plastic pallets | the export needs to be fumigated, which is quite complicated. |

Hotline:13549288845 peng Gong Phone number:0769-81788286 QQ:763598847

Update time:

TOP