Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

CROWNS METALWARE COMPANY LIMITED 15yr.

Contacts:Wang Qingshui Chat

Mobile:86-13757950753

E-mail:wqsjsswbzc@126.com

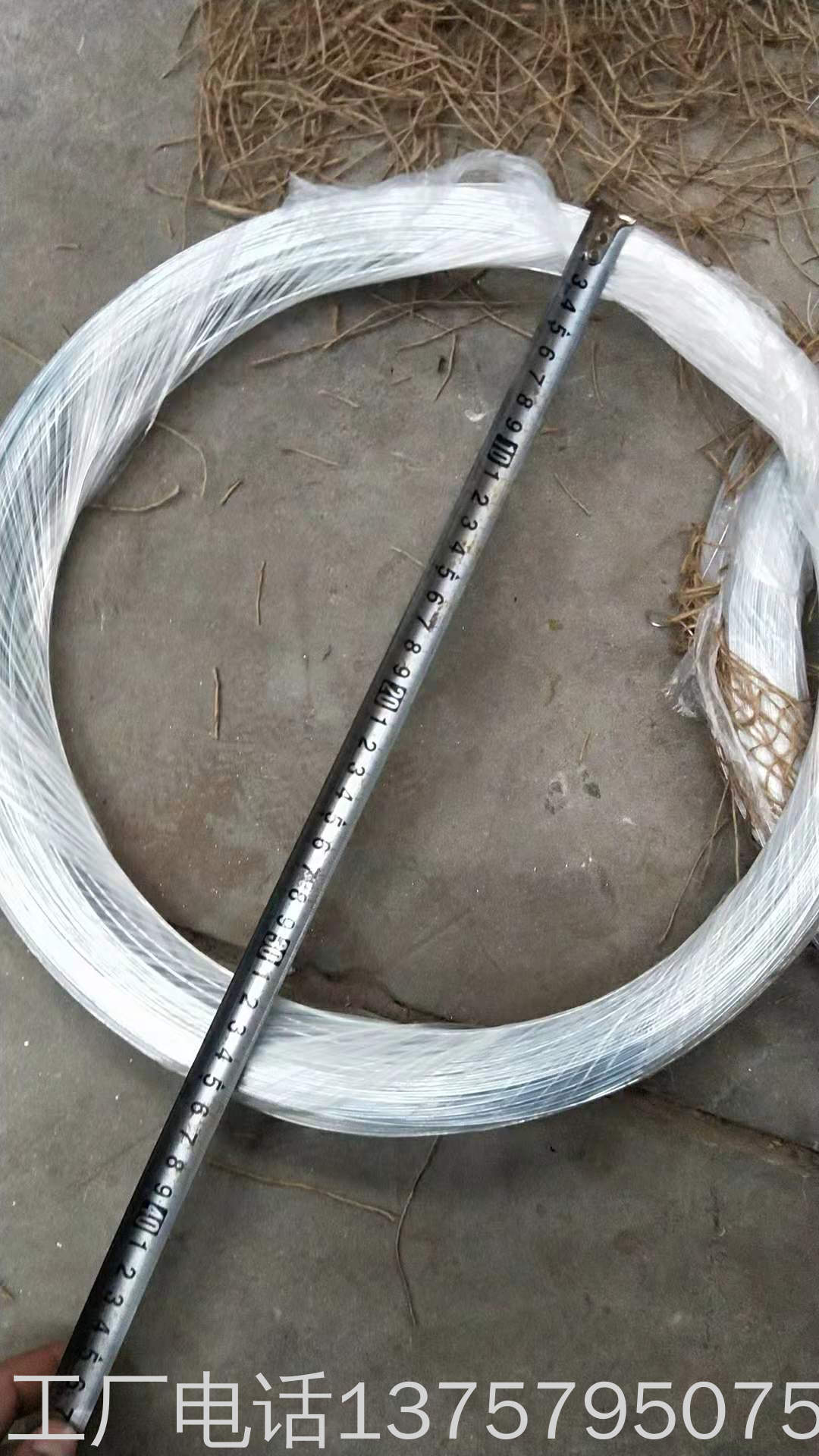

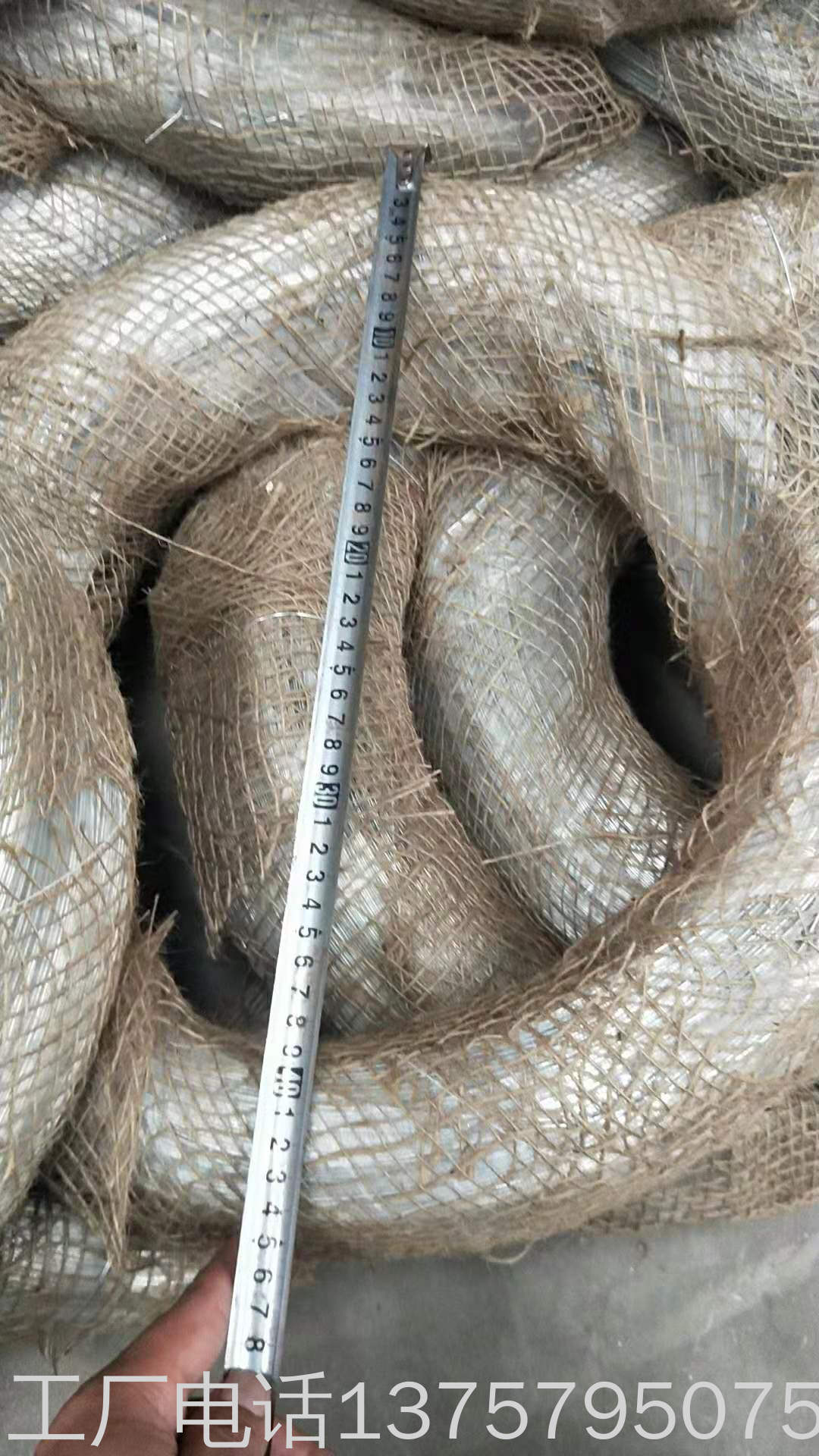

Production process: it uses high quality low carbon steel steel wire rod processed by high quality low carbon steel drawing molding, pickling derusting, high temperature annealing, hot dip galvanized. It is processed by cooling and other technological processes.

Features: galvanized iron wire it has good toughness and elasticity, and the maximum amount of zinc can reach 300g/square meter. With galvanized layer thick, strong corrosion resistance and other characteristics.

Zinc plated wire applications: products are widely used in architecture, handicrafts, weaving silk screen and expressways. Protective grating, product packaging, daily civil use and other fields.

Zinc plated wire divided hot galvanized wire and cold zinc plated wire( galvanized silk) the difference is:

hot dip galvanized it is immersed in heated and melted zinc solution, with fast production speed and thick but uneven coating, up to 300 Micron. The color is dark, the consumption of zinc metal is large, and the infiltration layer is formed with the base metal. The corrosion resistance is good, and the outdoor environment hot dip galvanized it can last for decades.

Cold galvanized(Galvanized) yes plating tank the internal current unidirectivity makes zinc gradually plated on the metal surface, the production speed is slow, and the coating is uniform,

the thickness is relatively thin, usually only 3-15 microns, with bright appearance and poor corrosion resistance. Generally, it will rust in a few months.

the thickness is relatively thin, usually only 3-15 microns, with bright appearance and poor corrosion resistance. Generally, it will rust in a few months.

Relatively hot dip galvanized, galvanized the production cost is low.

Difference between cold galvanizing and Hot Galvanizing:

the difference between cold galvanizing and Hot Galvanizing is that the amount of zinc is different, which can be identified from the color. Cold galvanizing is shiny and silvery white with yellow. Hot dip galvanized shiny hair white.

Application Scope of Hot Galvanizing:

because the resulting coating is thicker, hot dip galvanized it has better protective performance than galvanized, so it is an important protective coating for steel and iron parts in harsh working environment. Hot dip galvanized products are widely used in chemical equipment, petroleum processing, Marine Exploration, metal structure, electric power transmission, shipbuilding and other industries, and in agricultural fields such as pesticide sprinkler irrigation, greenhouse and construction such as water and gas transportation, wire casing, scaffolding, bridges, roadside fence and other aspects have been widely adopted.

Update time:

TOP