Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Yiwu Jianglong Sports Factory 14yr.

Contacts:Tan Fang Chat

Mobile:86-13375897718

E-mail:756260476@qq.com

Yiwu Jianglong Sports Products Co., Ltd. specializes in the production and sales of machine-sewn footballs, volleyballs, and rugby balls, among other ball products. The company is located in Yiwu City, Zhejiang Province.No. 311, Tianbao Road, Yiwu City, Zhejiang ProvinceYiwu Jianggelong Sports Goods Co., Ltd. has a complete and scientific quality management system. Since its establishment, the company has always adhered to the principles of high quality, high efficiency, and high reputation. Relying on its rich production experience, strong technical strength, advanced production equipment, and strict production and management concepts, it has gained recognition in the industry. We warmly welcome friends from all walks of life to visit, guide, and conduct business negotiations at Jianggelong Sports Goods Co., Ltd.!

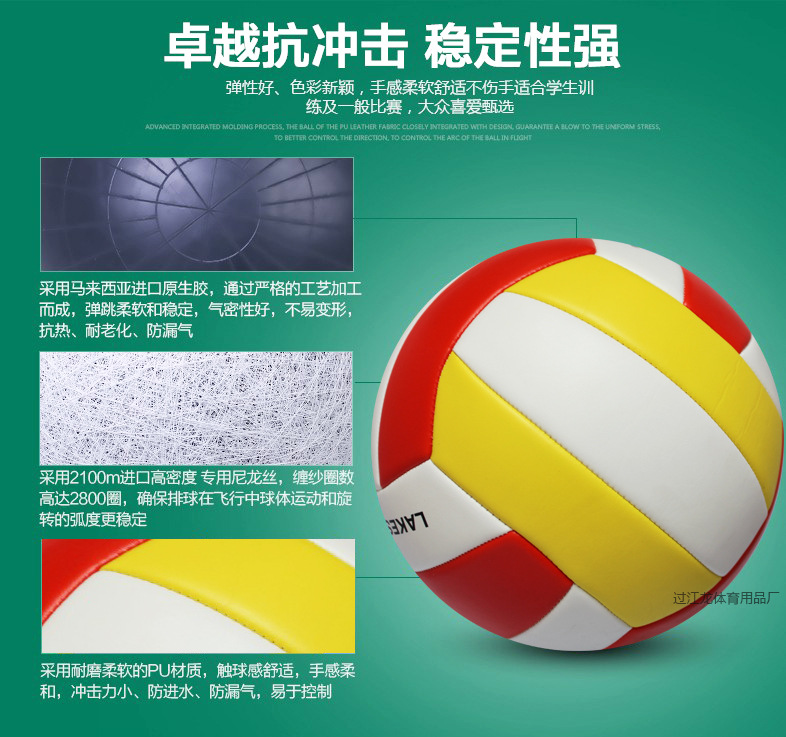

Product Details:

This product is made of PVC material, with a lightweight ball and good sweat absorption.Please provide the Chinese text you want to translate, and I will translate it into English for you.Multi-layer processing, finely crafted.

1)MaterialPVC

2)craftsmanshipfoaming

3)SpecificationComplete

4)inner pot:Rubber Bladder

5)Packing: Deflate1 piece/OPPBag

We can make products according to the requirements of our customers..Can be printed in different waysLOGO,Welcome new and old customers to visitExclamation mark

Product Display:

Football Production and Process

1Material Selection

In the same materials, our company provides the best materials to our customers. This is a responsibility to the customer. The factory does not want a customer to do only once. I hope my customers will be satisfied with the first transaction and every transaction in the future. Let the customer continue to produce in our factory. Then selecting materials is a key.

2Cutting the skin

Cutting the leather is the process of cutting the material of the product. It is a very important step in the production process of footballs. Throughout the cutting process, a quality inspector is involved, supervising to ensure that the leather cut is accurate and error-free. At the same time, the cutters have rich experience, multiple guarantees to ensure the quality of the product material.

3Chest Wall Deformity Examination

The product production also includes a process: leather cutting inspection. From the full-time supervision of the leather cutting process to the re-inspection after the completion of the leather cutting, every production process will be done with the most meticulous attention.

4Leather Printing

Printing leather materials, various different patterns and colors of leather materials are produced, after printing, the most important thing to do is quality inspection, to ensure that all printed leather materials are qualified. Only then can we proceed to the next process.

5Machine Stitch

First, the flat car creates a complete ball pattern. After passing the quality inspection, it is placed on the high car for assembly. After completing the same process, the quality inspection is passed, and the master proceeds to the next process.

6、装胆

This place is very particular because many beginners install the ball bladder crookedly, leading to the entire ball being substandard. That's why our factory's master craftsmen have years of experience to ensure that the ball doesn't fall apart or become crooked after installation.

7Closure

Closing is a skillful task that requires technology. The precision of the process has a significant impact on the quality of the product. During the closing process of the product, employees are given ample time to ensure that each ball is well made.

8Inspection

Quality inspection is never lacking. To produce good products, it is crucial to conduct quality checks after the entire process is completed. There may be some human errors during the process.

9Inflation, printing, cleaning, and testing to packaging

Inflate the shape, and the basic shape of a football is formed. Then, clean away the dust or residual latex, and then weigh it to ensure that each ball is maintained at a certain weight. The only thing to do is to test the air pressure, the ball will be placed on a rack and stored in the factory.72Hour, the second check will be72The process will be conducted after one hour, this is to eliminate all possible human factors. Ensure that the final products have the quality. The last step is to conduct a comprehensive quality check after air testing. For example, measuring the circumference of the ball, the target for a competitive ball is precise to690mmAll those who are in" 或者 "All those who are685mmand695mmThe ball is only recognized between them.

Update time:

TOP