Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Starstrong Fasteners 4yr.

Contacts:elissa Chat

Mobile:86-18072687675

E-mail:elissa@xingfenghardware.com

A gasket is a mechanical seal between two objects, usually used to prevent pressure, corrosion, and the natural thermal expansion and contraction of the pipe from leaking. Since the machining surface cannot be very good, using a gasket can fill the irregularity. Gaskets are usually made of sheet materials, such as gasket paper, rubber, silicone rubber, metal, cork, felt, chloroprene rubber, nitrile rubber, glass fiber, or plastic polymers (such as polytetrafluoroethylene). Gaskets for specific applications may contain asbestos.

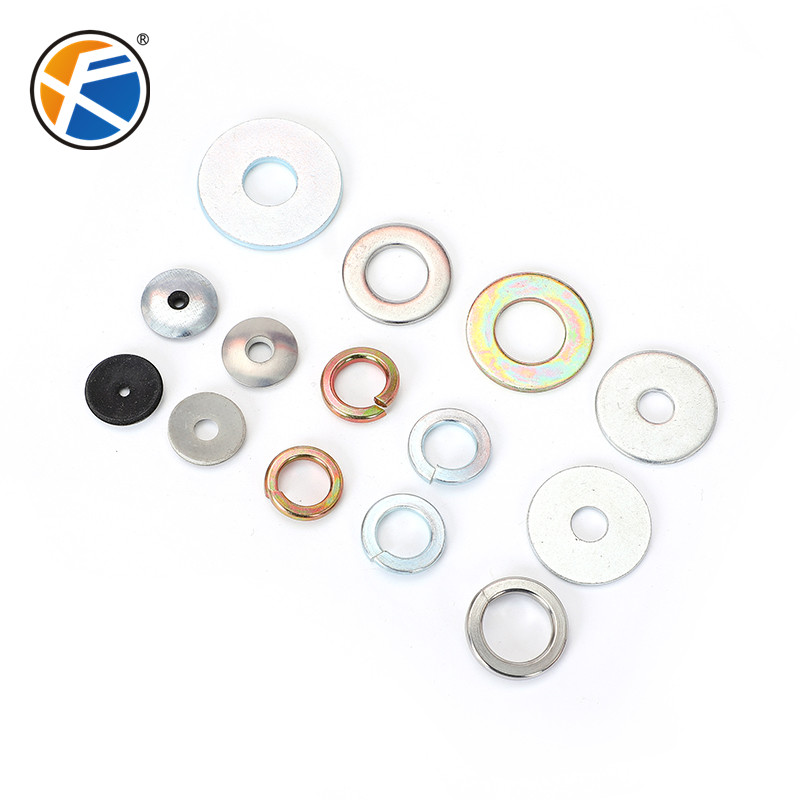

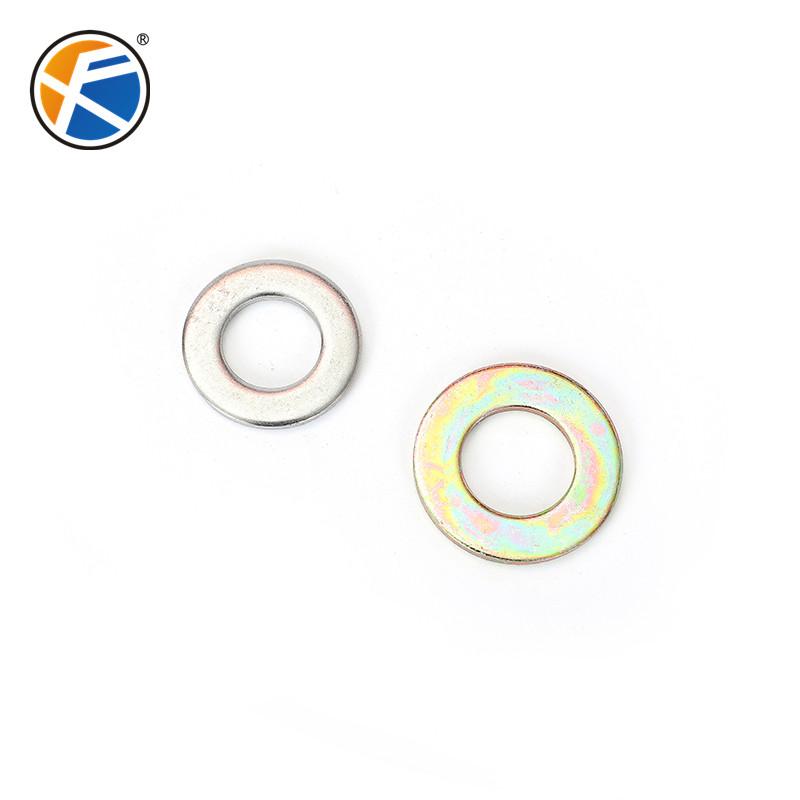

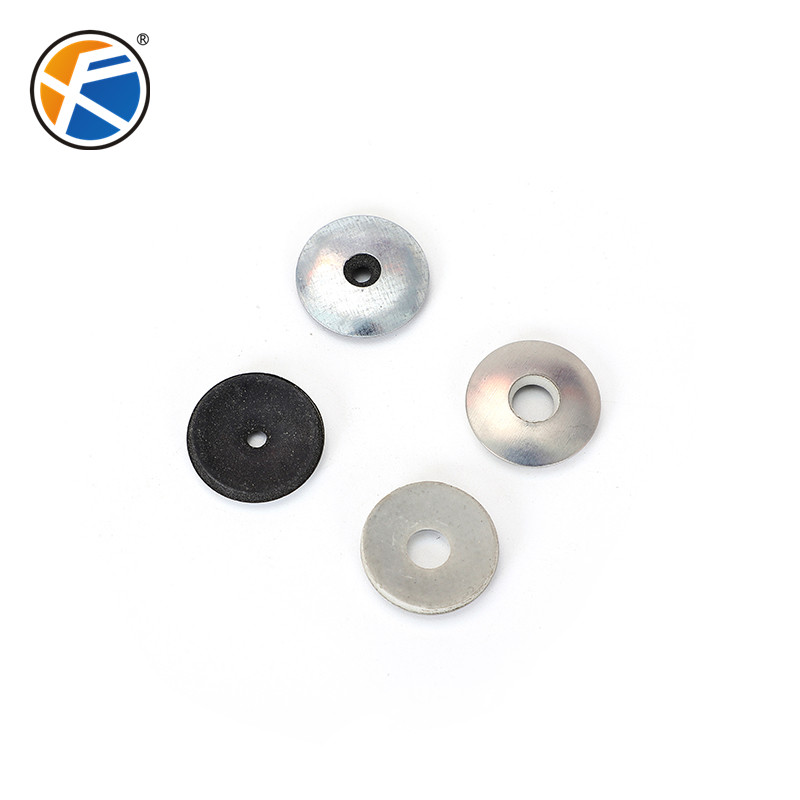

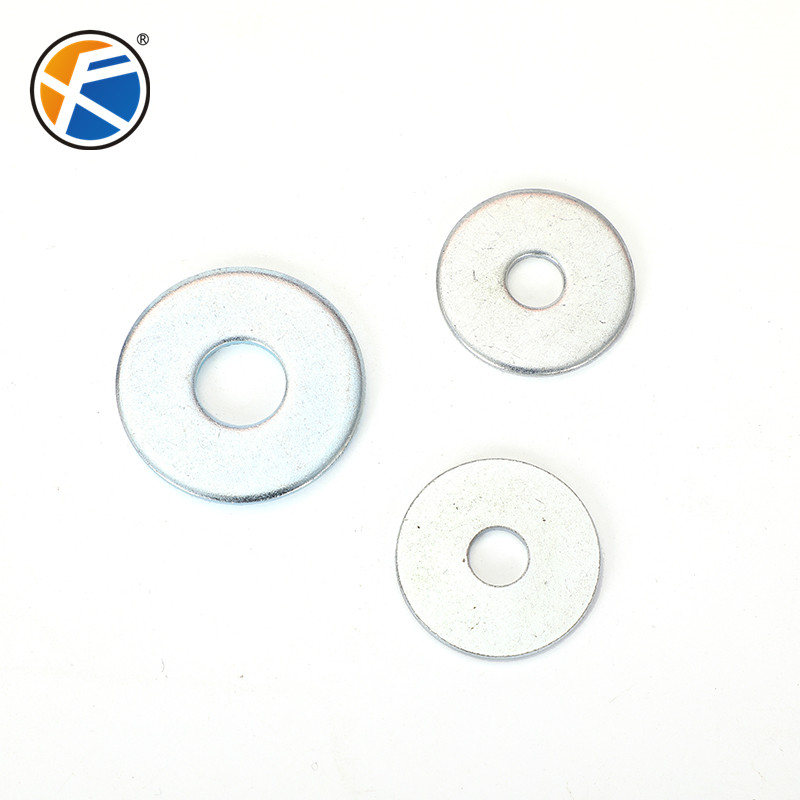

A washer is a thin plate (usually circular) with a hole in the middle, typically used to distribute loads and to tighten fasteners. Other uses include as spacing, spring (Bellville washers, wave washers), wear-resistant washers, pre-tensioning devices, locking devices. Rubber washers are also used on faucets (valves) to cut off the flow of liquids or gases. Rubber or silicon washers can also be used to reduce vibration in fans. The outer diameter of a washer is typically about twice the inner diameter.

A gasket is a mechanical seal between two objects, usually used to prevent pressure corrosion and the natural expansion and contraction of pipes. Since machined surfaces can never be perfect, shims can be used to fill in irregularities. Spacers are usually made of sheet materials such as pad paper, rubber, or silicone rubber.metal cork felt neoprene nitrile butadiene rubber fiberglass or plastic polymers such as teflon Gaskets for specific applications may contain asbestos

The washer is a leak usually in the middle of the sheet usually round usually used to distribute the load thread fasteners Other uses are as spacers springs Belleville gaskets wave gaskets wear pads predisplay devices locking devices Rubber washers are also used in faucets valves to cut off the flow of liquid or gas.Rubber or silicon shims may also be used to reduce fan vibration. Usually, the outer diameter of the gasket is about twice the inner diameter.

Fold and edit this section type

Gaskets can be divided into non-metallic gaskets, metal gaskets, metal-non-metallic combination gaskets according to their material and structural characteristics, and each type can be further subdivided into several kinds.

Folding non-metallic gasket

Rubber gasket

无石棉纤维橡胶垫片

Flexible graphite metal composite gasket

Teflon gasket

Teflon coated gasket

Other types of non-metallic material gaskets

gasket

gasket

Folding metal-nonmetallic composite gasket

Corrugated gasket

Metal wound gasket

Metal tooth compound gasket

Metal coated gasket

Metal wave tooth composite gasket

Other types of metal composite gaskets

Folding metal gasket

Metal flat gasket

Metal corrugated gasket

Metal toothed gasket

Metal ring gasket

Metal lens gasket

O-ring pad of metal

The metal ring gasket can be divided into.

Octagonal ring pad

Elliptic ring pad

RX and BX type self-tightening ring pads

Fold and edit this section material classification

The part of the washer placed between the connector and the nut, usually a flat metal ring.

Metallic gasket and non-metallic gasket made of asbestos, rubber, synthetic resin, Teflon and other non-metallic materials. A non-metallic coated gasket is a non-metallic jacket gasket with a layer of synthetic resin, etc.

Semimetallic Gasket A gasket made of metallic and nonmetallic materials such as winding gasket metal-coated gasket a spiral wound gasket A gasket consisting of a metal belt with a V-shaped or W-shaped section and a nonmetal belt 1 The inner ring is a metal ring arranged in the inner ring of the winding gasketThe outer ring is a metal ring arranged in the outer ring of the wound gasket. Metal cladding

metallic gasket A gasket made of metal such as steel, aluminum, copper, nickel, or monel.

Winding gasket refers to the metal belt generally V-shaped steel belt and nonmetallic belt winding into a ring gasket, where metal belts and nonmetallic belts are wound alternately. Due to its good elasticity, it is widely used in the petrochemical, chemical, electric power, and other industries for flange seal structures.According to the specific position, the gasket can be located in the inner or outer layer with a steel ring to locate or strengthen.

GB/T 4622.1-2009 缠绕式垫片分类

Gaskets for flanges of wound gaskets GB/T 4622.2-2008

GB/T 4622.3-2007 缠绕式垫片技术规格

GB/T 9126-2008 Pipe flanges - Non-metallic flat gaskets - Dimensions

GB/T 9128-2003 Steel pipe flanges -- metallic ring gaskets -- Dimensions

Specification for non-metallic flat gaskets for pipe flanges

Specification for metal ring gaskets for GB/T 9130-2007 steel pipe flanges

Gaskets for large diameter steel pipe flanges

GB/T 13404-2008 Pipe flanges with non-metallic polytetrafluoroethylene coated gaskets

Metal coated gaskets for pipe flanges

GB/T 19066.1-2008 Flexible graphite metal wave tooth composite gasket dimensions

GB/T 19066.3-2003 Flexible graphite metal wave tooth complex gaskets -- technical specifications

GB/T 19675.1-2005 管道法兰用金属冲压板用柔性石墨复合垫片 - 尺寸

GB/T 19675.2-2005 管道法兰用金属冲制板柔性石墨复合垫片 - 技术规范

JB/T 87-1994 管道法兰石棉橡胶垫片

JB/T 88-1994 Pipe Flange Metal Tooth Gaskets

JB/T 89-1994 Metallic ring gaskets for pipe flanges

JB/T 90-1994 管道法兰用卷制垫片

JB/T 6369-2005 柔性石墨金属缠绕垫片技术规格

JB/T 6618-2005 金属卷绕垫片用聚四氟乙烯带规范

JB/T 8559-1997 Metal covered gasket

JB/T L 0688-2006 聚四氟乙烯垫片技术规格

JB/T L 0689-2006 膨胀聚四氟乙烯密封带技术规格

SH 340111996 Asbestos rubber plate gaskets for pipe flanges

SH 3402 1996 Teflon coated gaskets for pipe flanges

SH 3403-1996 Metal ring pads for pipe flanges

SH 3407-1996 Pipe Flange Winding Gaskets

HG/T20592~20635-2009 steel pipe flanges, gaskets, fasteners

GB/T L 047-2005 Pipe element DN(nominal size) definition and selection

GB/T 1048 2005 Pipe element PN (nominal pressure) definition and selection

GB/T 12385-2008 Pipe flanges gasket performance test method

GB/T 12621-2008 Pipe Flanges Gasket Stress Relaxation Test Method

GB/T 12622-2008 Pipe flanges -- Test method for compression and resilience of gaskets

GB/T 20671.1-2006 Non-metallic gasket materials classification system and test methods - Part 1: Classification system of non-metallic gasket materials

Non-metallic gasket materials - Classification system and test methods - Part 2: Test method for compression rate and resilience of gasket materials

Non-metallic gaskets -- Classification systems and test methods -- Part 3: Test method for liquid resistance of gaskets

Non-metallic gasket materials - Classification system and test methods - Part 4: Test method for sealing of gasket materials

Non-metallic gaskets -- Classification systems and test methods -- Part 5: Test method for creep relaxation rate of gaskets

Non-metallic gasket materials - Classification systems and test methods - Part 6: Test method for adhesion of gasket materials to metal surfaces

GB/T 20671.7-2006 Non-metallic gaskets materials - Classification system and test methods - Part 7: Test method for tensile strength of non-metallic gaskets

Non-metallic gasket materials - Classification systems and test methods - Part 8: Test method for softness of non-metallic gasket materials

Non-metallic gasket materials - Classification systems and test methods - Part 9: Test method for durability of cements of cork gasket materials

Non-metallic gasket materials - Classification systems and test methods - Part 10: Method for determination of thermal conductivity of gasket materials

Non-metallic gasket materials - Classification systems and test methods - Part 11: Method for determination of mildew resistance of synthetic polymer materials

GB/T 539-2008 耐油石棉橡胶板

GB/T 540 2008 Test methods for oil-resistant asbestos rubber sheets

GB 912-2008 Hot-rolled sheet and strip of carbon structural steel and low alloy structural steel

GB/T 3280-2007 Stainless steel cold rolled steel plates and strips

GB/T 3985-2008 石棉橡胶板

GB/T 4238-2007 耐热钢板和钢带

GB/T 5574-2008 Rubber sheet for industrial use

GB/T 11253-2007 carbon structural steel cold rolled sheet and strip

JB/T 6628-2008 柔性石墨复合增强(板)垫

JB/T 7758.1-2008 柔性石墨板 - 氟含量的测定

JB/T 7758.2-2005 柔性石墨板技术规格

JB/T 7758.3-2005 柔性石墨板 - 硫含量的测定

JB/T 7758.4 2008 - Determination of Chlorine Content in Flexible Graphite Plates

JB/T 7758.5-2008 柔性石墨板 - 线性膨胀系数的测定

JB/T 7758.6-2008 柔性石墨板 - 肖氏硬度测试方法

JB/T 7758.7-2008 柔性石墨板应力松弛试验方法

JB/T 9141.1-1999 柔性石墨片密度试验方法

Fold and edit the installation requirements for this section

Gaskets - Installation requirements for sealing gaskets

1. The sealing surface of the gasket and flange should be cleaned, and there should be no scratches, spots and other defects affecting the sealing performance of the connection.

The outer diameter of the sealing gasket should be smaller than the flange sealing surface, and the inner diameter of the sealing gasket should be slightly larger than the inner diameter of the pipeline. The difference between the two inner diameters is generally 2 times the thickness of the sealing gasket.To ensure that after compression, the inner edge of the sealing gasket does not extend into the container or pipeline, thus not hindering the flow of fluid in the container or pipeline.

3, sealing gasket preload should not exceed the design provisions, so as to avoid excessive compression of the sealing gasket loss of resilience.

4. When sealing gasket is pressed, it is best to use a torque wrench. For large bolts and high strength bolts, it is best to use a hydraulic tensioner. The tightening torque should be calculated according to the given sealing gasket compaction, and the oil pressure of the hydraulic tightener should also be determined by calculation.

5. When installing sealing gaskets, tighten the nuts in sequence. But should not screw once to reach the design value. Generally, it should be cycled at least 2~3 times, so that the stress distribution of the sealing gasket is uniform.

6. For pressure vessels and pipelines with inflammable and explosive media, safety tools should be used when replacing sealing gaskets to avoid the collision between tools and flanges or bolts, resulting in sparks and fire or explosion accidents.

7. If there is leakage in the pipeline, the sealing gasket must be replaced or adjusted after pressure reduction treatment. It is strictly prohibited to operate with pressure.

Amend and edit the applicable scope of this paragraph

The choice of gasket material mainly depends on the following three factors: temperature, pressure, and the medium.

I. Metal gasket material

The recommended maximum operating temperature for carbon steel is not more than 538°C, especially when the medium has oxidation. High-quality thin carbon steel plate is also not suitable for the manufacture of equipment for inorganic acid neutral or acidic salt solution if carbon steel is subjected to stress in hot water conditions. The accident rate of equipment is very high.Carbon steel gaskets are usually used for high concentrations of acid and many alkali solutions. The Brinell hardness is about 120.

2. 304 stainless steel 18-8 (chrome 18-20%, nickel 8-10%), the recommended maximum operating temperature is not more than 760℃. In the temperature range of -196~538℃, stress corrosion and grain boundary corrosion are easy to occur. Brinell hardness 160.

3. The carbon content of 304L stainless steel does not exceed 0. 03%. The maximum operating temperature is not more than 760 ° C. Corrosion resistance similar to 304 stainless steel. The low carbon content reduces the precipitation of carbon from the lattice, and the resistance to grain boundary corrosion is higher than that of 304 stainless steel. The Brinell hardness is about 140.

4316 stainless steel, with a composition of 18% chromium and 12% nickel, in 304 stainless steel, the addition of about 2% molybdenum increases its strength and corrosion resistance as the temperature rises. Compared to other ordinary stainless steels, it has higher creep resistance at elevated temperatures. The maximum operating temperature should not exceed 760°C. The Brinell hardness is approximately 160.

5. The recommended maximum continuous operating temperature of 316L stainless steel is not more than 760℃~815℃. Carbon content is not more than 0.03%, which makes 316 stainless steel have better stress resistance and grain boundary corrosion resistance. The Brinell hardness is about 140.

6. Alloy 20 consists of 45% iron, 24% nickel, 20% chromium, and a small amount of molybdenum and copper. The recommended maximum operating temperature ranges from 760 ° C to 815 ° C. It is especially suitable for manufacturing sulfuric acid corrosion resistant equipment, with a Brinell hardness of about 160.

7. Aluminum alloy (content not less than 99%). Aluminum has excellent corrosion resistance and machining properties, suitable for the manufacture of double clamp gaskets. Brinell hardness is about 35. The maximum continuous operating temperature is not more than 426 ° C.

8. Copper Copper is similar in composition to pure copper and contains trace amounts of silver to increase its continuous operating temperature. The maximum continuous operating temperature is recommended to be less than 260 ° C. Brinell hardness is about 80.

9. Brass (66% copper, 34% zinc), in most working conditions, has good corrosion resistance, but not suitable for acetic acid, ammonia, salt and acetylene. The maximum continuous operating temperature is recommended to be less than 260 ° C. The Brinell hardness is about 58.

10 Hastelloy B2 2630 molybdenum 62 nickel and 46 iron The maximum operating temperature does not exceed 1093 ° C It has excellent corrosion performance of hydrochloric acid in heat resistant concentration It also has excellent resistance to the corrosion of wet hydrogen chloride gas sulfuric acid phosphoric acid and reducing salt solutionHigh strength under high temperature conditions. The Brinell hardness is about 230.

11 Hastelloy C276 1618 molybdenum 13175 chromium 3753 tungsten 457 iron the rest are nickel The maximum operating temperature does not exceed 1093 ° C Excellent corrosion resistance It has excellent corrosion resistance to all kinds of cold nitric acid or boiling nitric acid with a concentration of 70It has good corrosion resistance to hydrochloric acid and sulfuric acid and excellent stress corrosion resistance. The Brinell hardness is about 210.

12. Incornel 600 nickel base alloy (77% nickel, 15% chromium and 7% iron). The maximum operating temperature does not exceed 1093 ° C. High strength under high temperature conditions, commonly used to solve the problem of stress corrosion equipment. At low temperature, it has excellent co-processing performance. Brinell hardness is about 150.

A gasket is a device that is used to prevent the passage of gases or liquids through a small opening or joint in a sealing application. It is typically made of rubber, plastic, or metal, and is designed to provide a tight seal to prevent leakage.

Update time:

TOP