Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Starstrong Fasteners 4yr.

Contacts:elissa Chat

Mobile:86-18072687675

E-mail:elissa@xingfenghardware.com

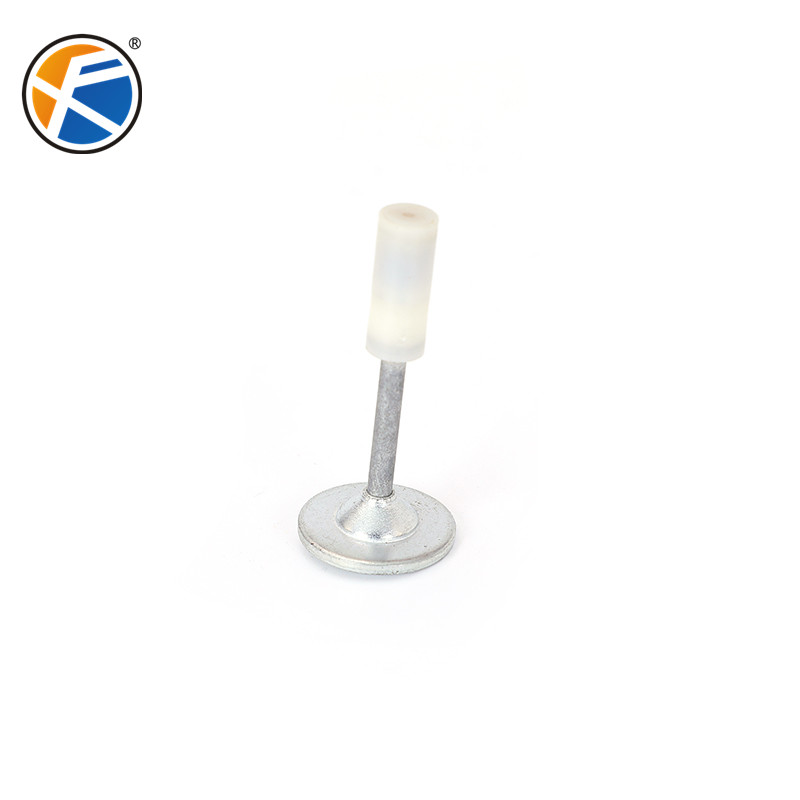

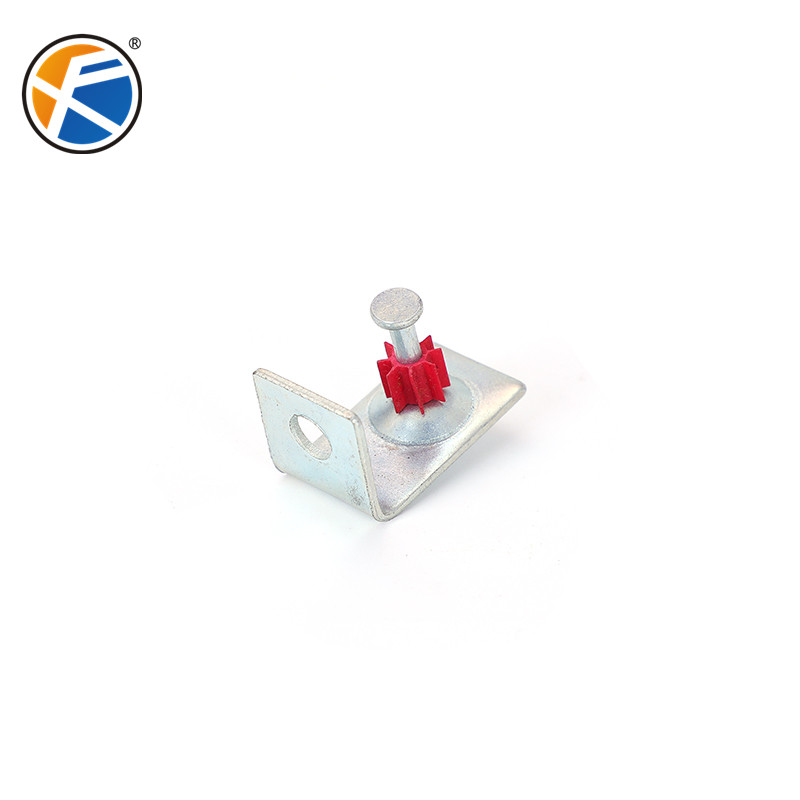

Shotting nail is a method of driving a nail into a building structure using the propulsive force generated by the combustion gases from a blank cartridge. It typically consists of a nail with a tooth ring or a plastic positioning ring.

Steel, which is often referred to as steel nails.

The nail is driven into the building body by using the power generated by the gunpowder gas from firing blank cartridges. It is usually composed of a nail with a tooth ring or a plastic positioning ring. The role of the tooth ring and the plastic positioning ring is to fix the nail body in the gun barrel of the nail gun to prevent side deviation when firing.

The function of a shotting nail is to drive it into a base such as concrete or steel plate to serve as a means of securing and connecting.

The material for shotting nails is generally 60# steel, which undergoes heat treatment. The core hardness of the finished product is HRC52-57. It can penetrate Q235 steel plates with a thickness of 0.8mm-1.2mm.

A shooting nail is a nail driven into a building using the gunpowder gas generated by firing a blanks. It usually consists of a nail with a toothed ring or plastic locating ring.

那些由钢制成的通常被称为钢钉。

A nail that is driven into a building using the gas generated by the firing of a blank. It usually consists of a nail with a tine or a plastic locating ring. The function of the ring and the plastic retaining ring is to hold the nail in the barrel of the nail gun so that it does not deflect sideways during firing.

The function of the nail shooting nail is to drive the nail into the substrate, such as concrete or steel plate, to provide a tight connection.

The nail shooting nail is generally made of 60# steel, heat-treated, with a core hardness of HRC 52-57, and can shoot through Q235 0.8mm-1.2mm steel plates.

Update time:

TOP