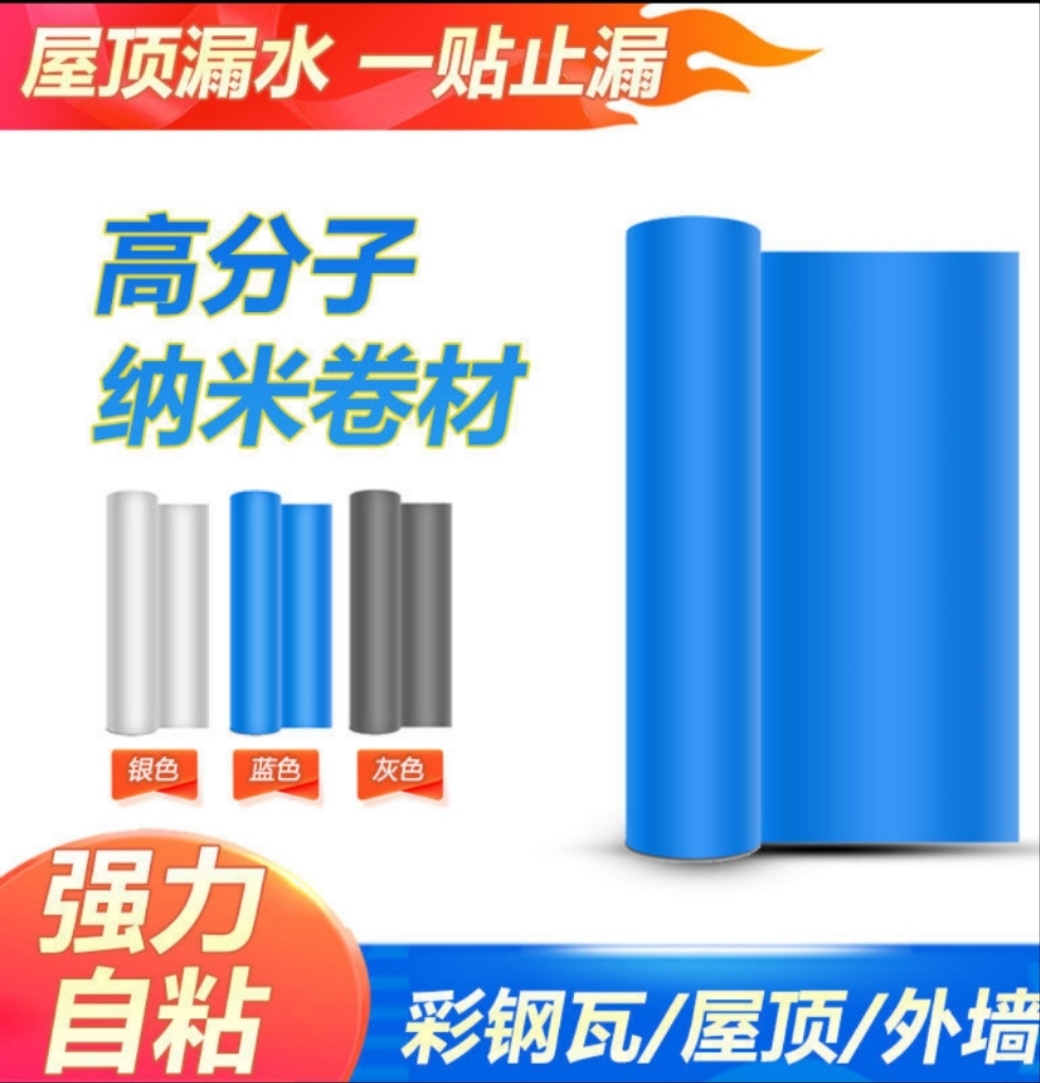

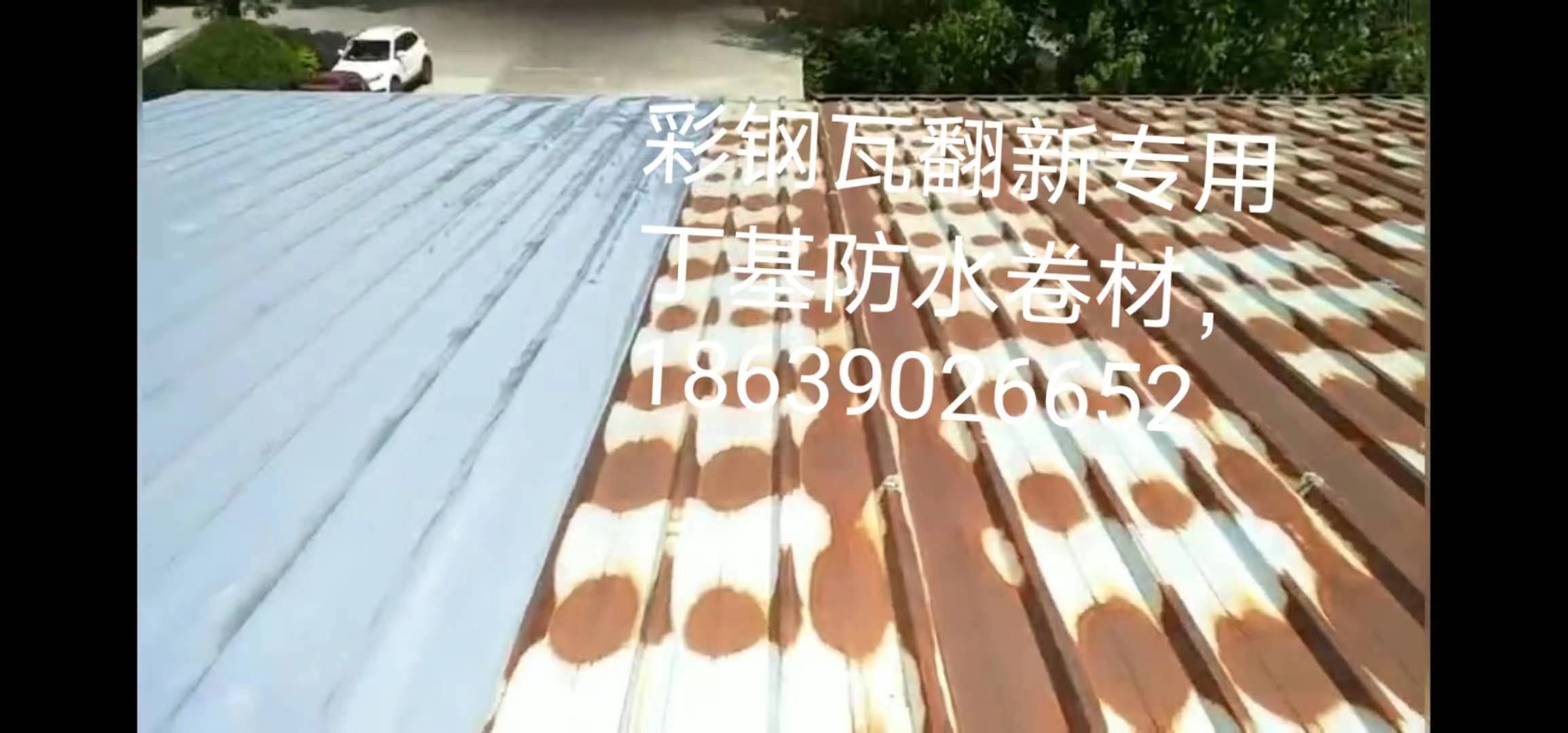

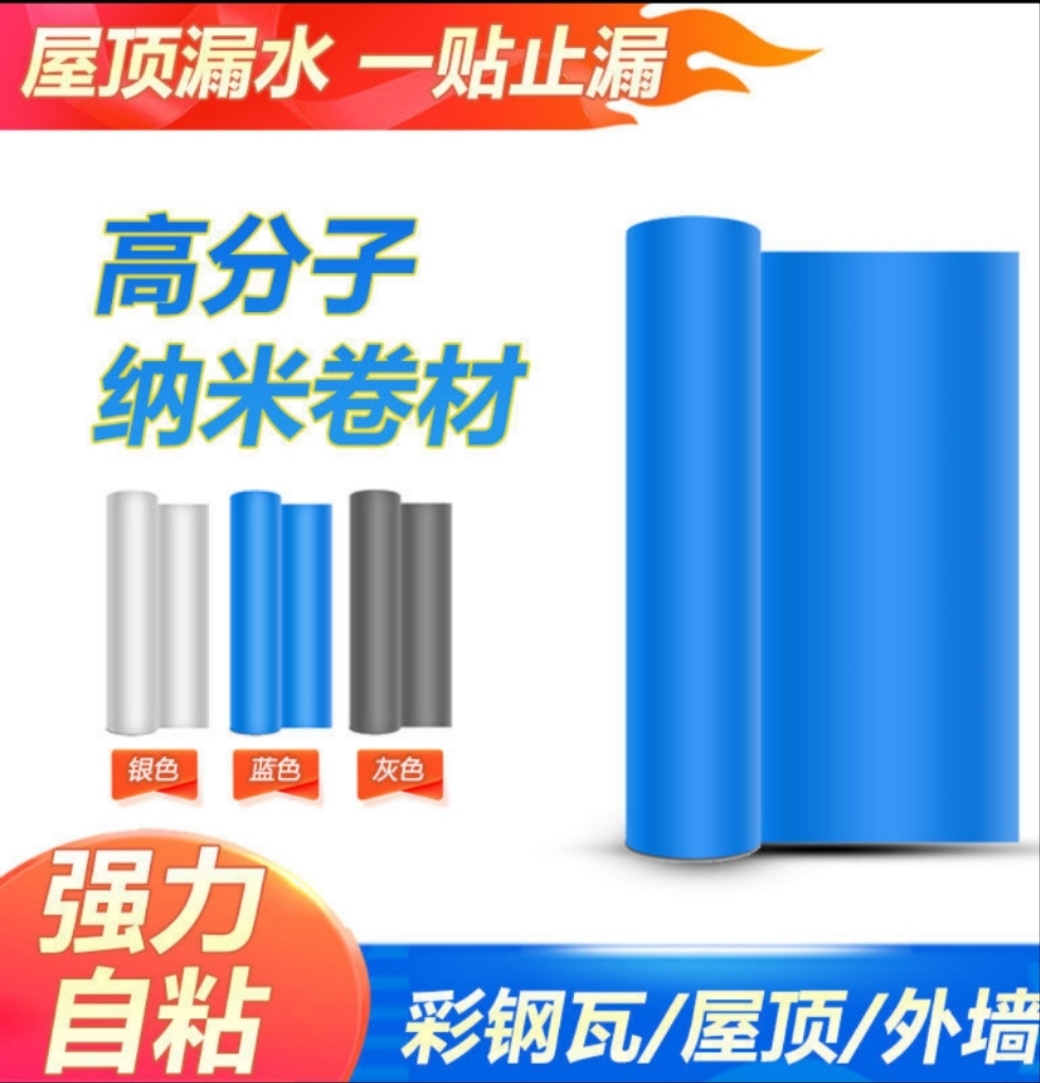

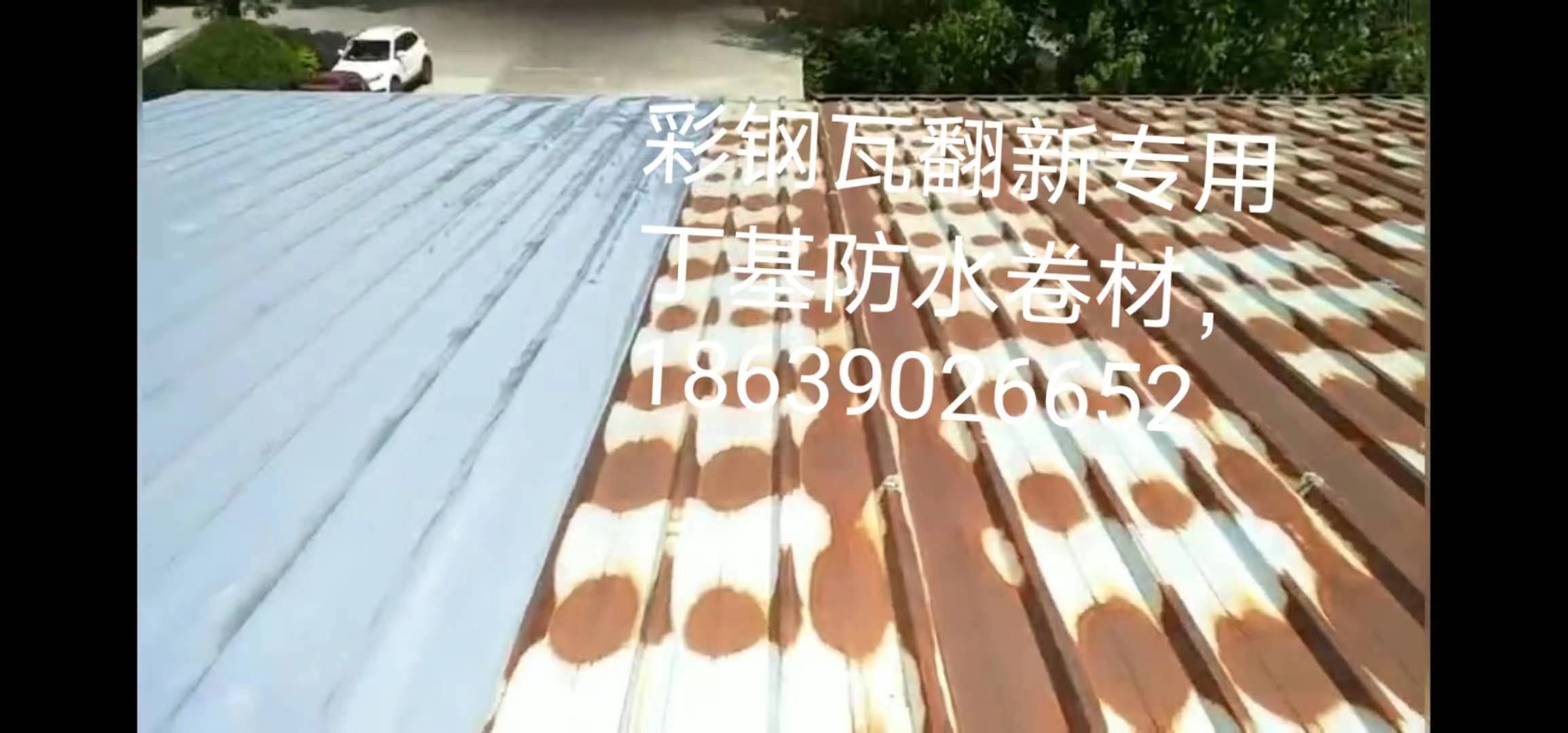

Custom-made roof insulation blanket aluminum foil self-adhesive waterproof membrane roofing repair waterproof material for color steel sheet metal roof

Color steel sheet waterproof material self-adhesive membrane roof leakage repair tape non-butyl non-asphalt special glue for single-story house

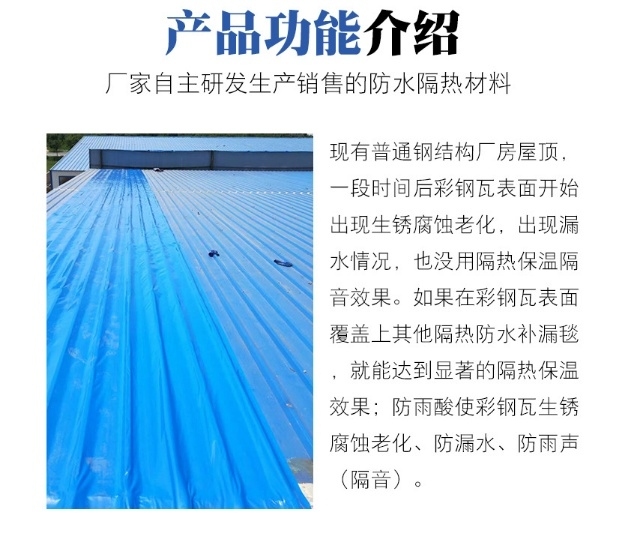

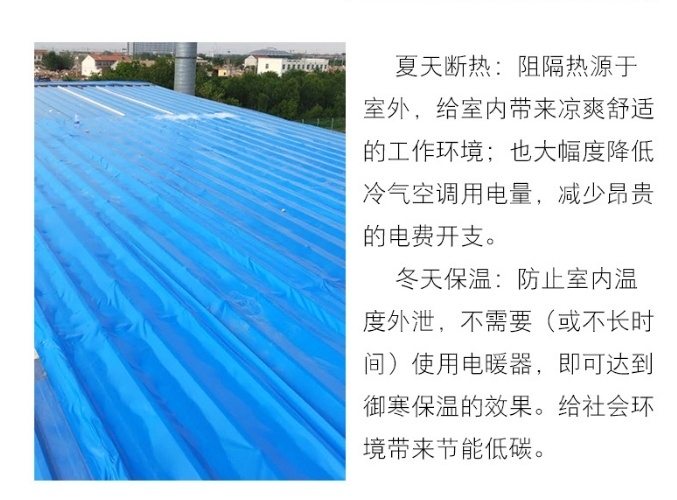

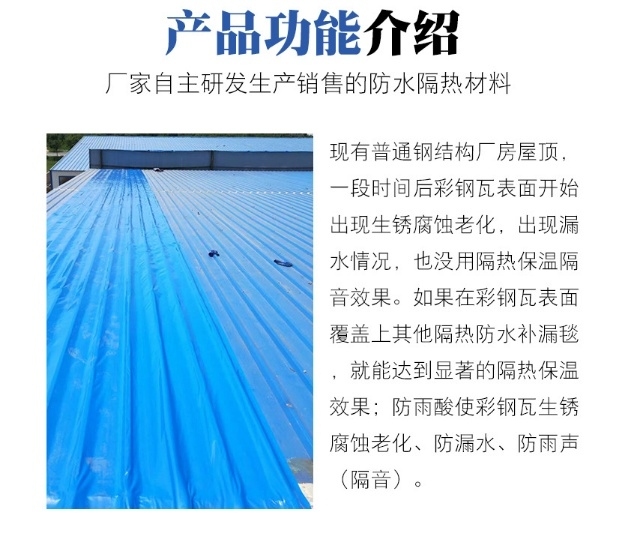

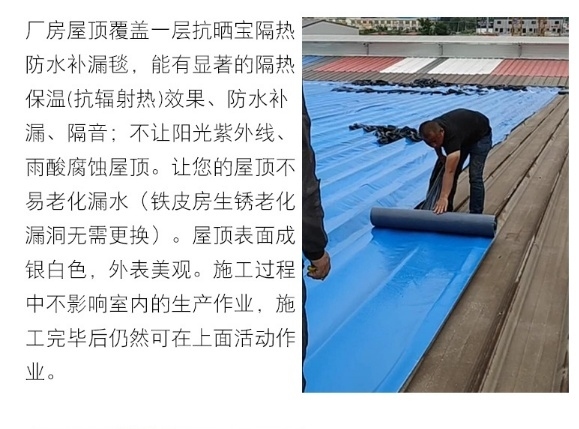

Self-adhesive waterproof and insulation membrane, full-coverage on rusty and leaky corrugated metal roofs, cement-surfaced roof tops, aging and leaky felt sheets, glass-roofed water-proof and insulation, simple construction, no need for fire-baking or glue application, directly adhesive, once applied, can last over ten years.

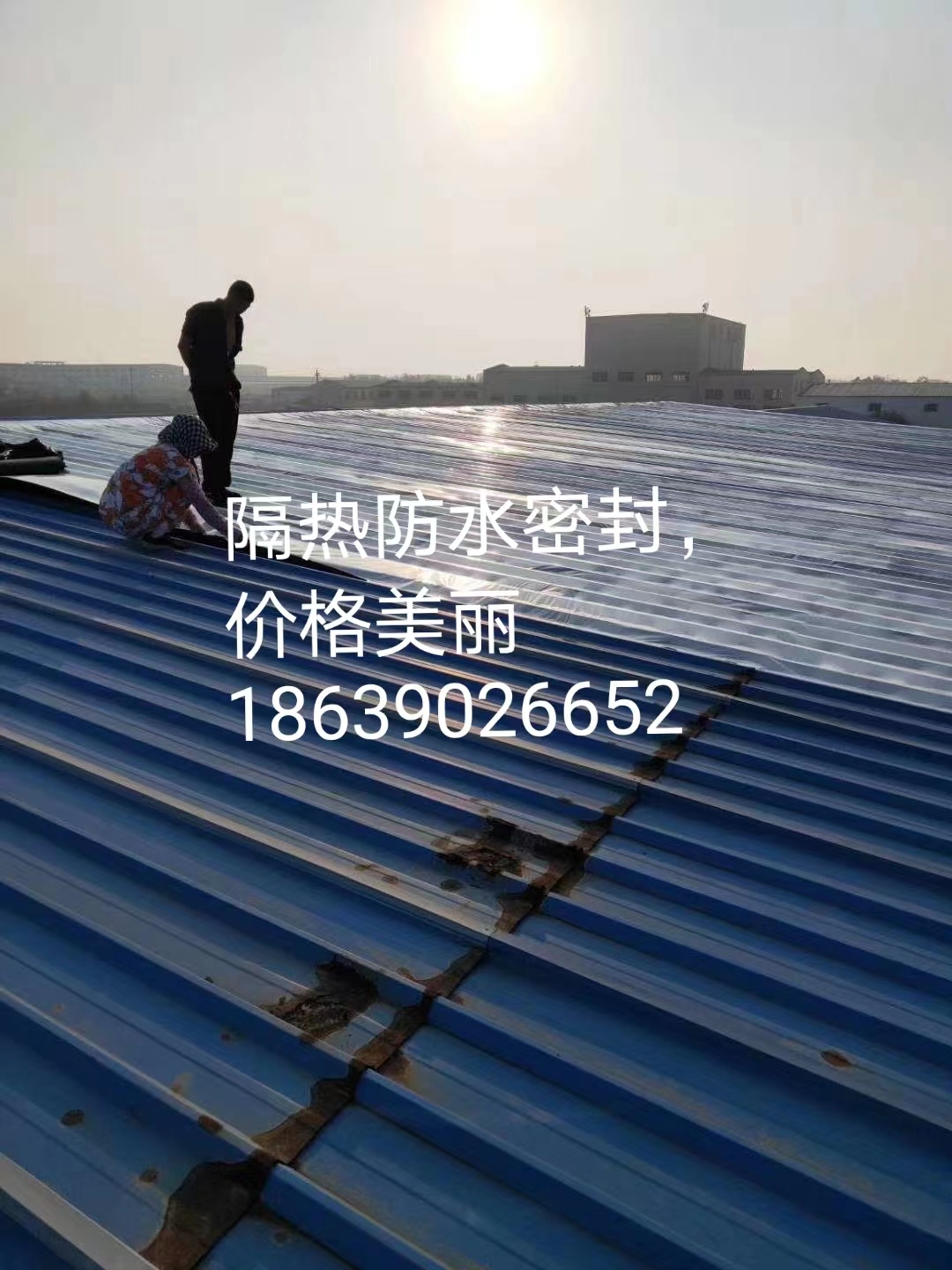

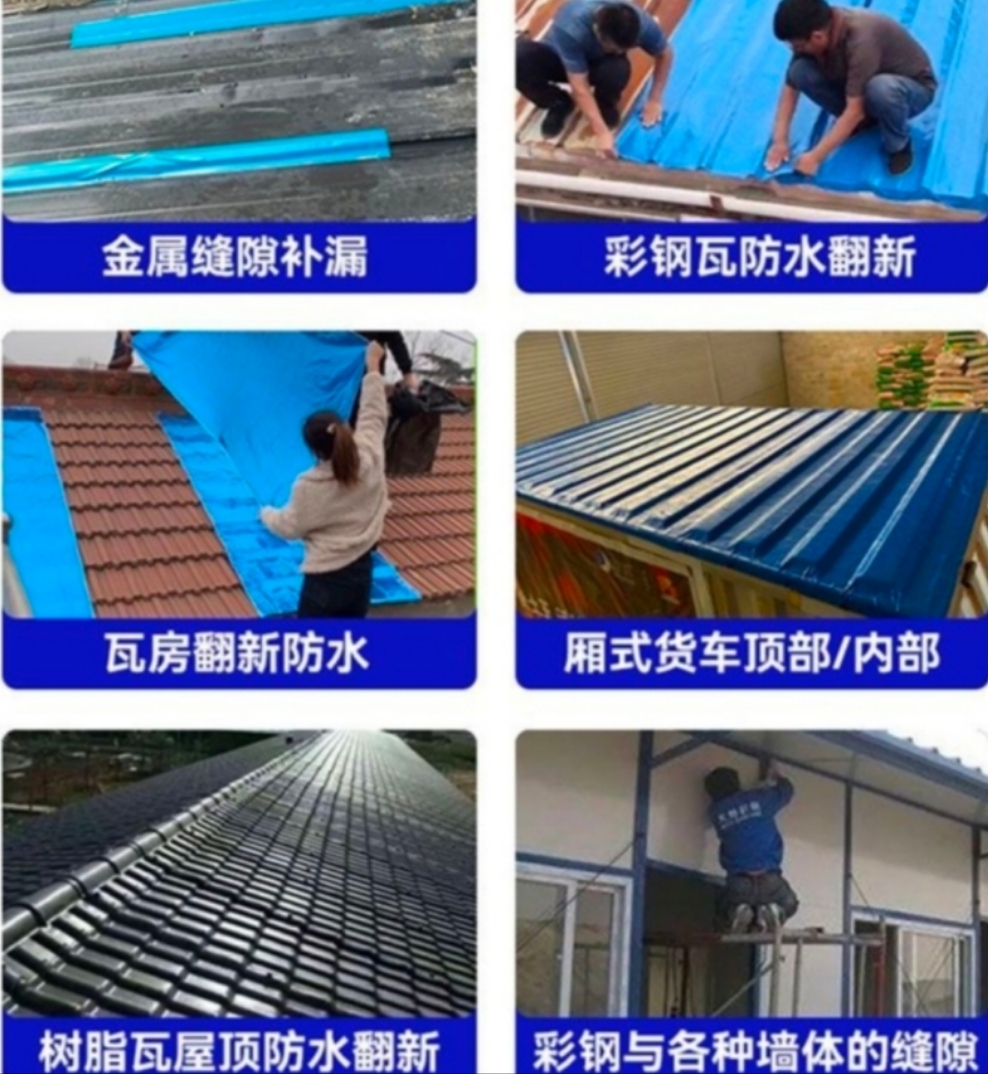

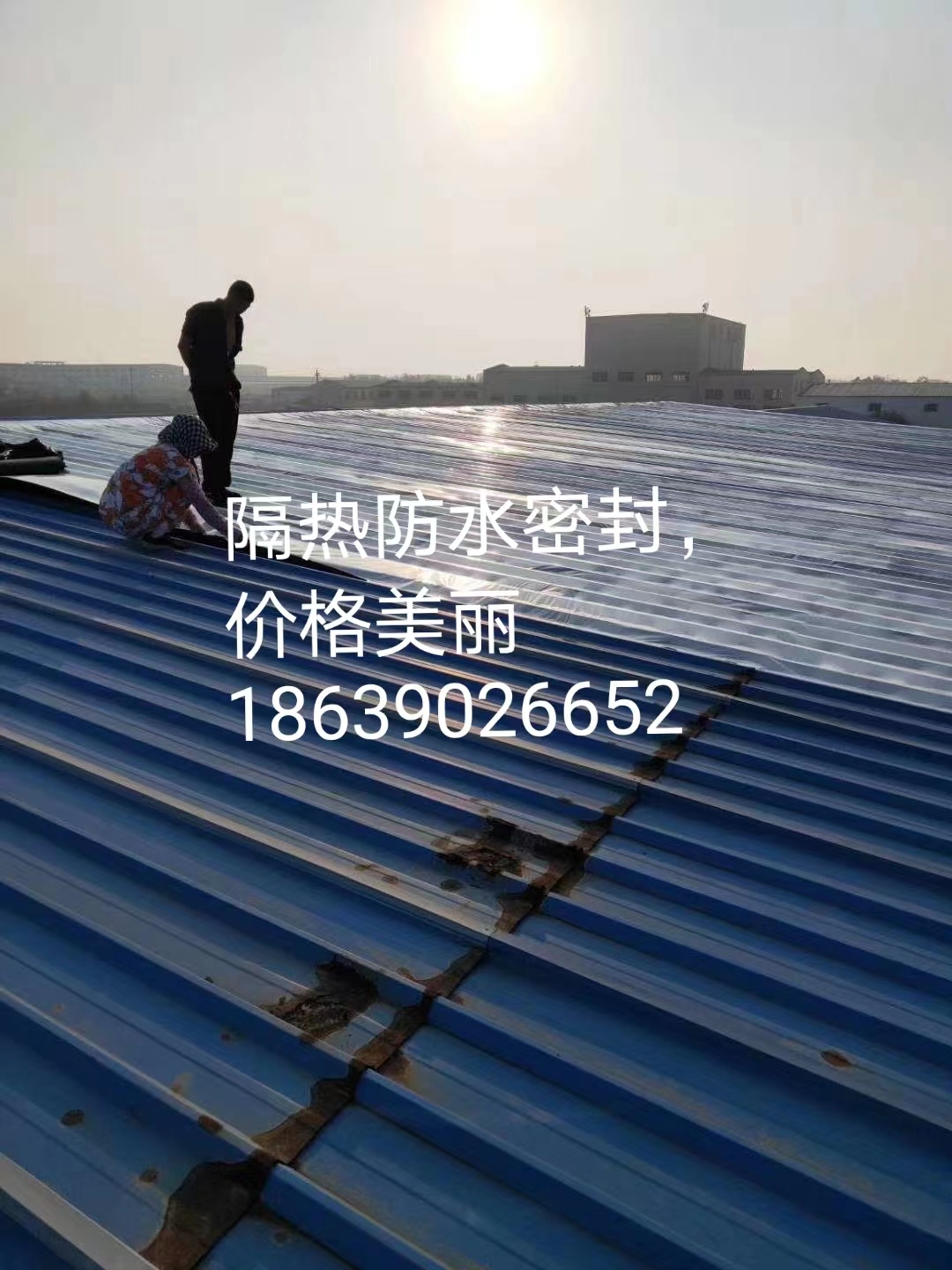

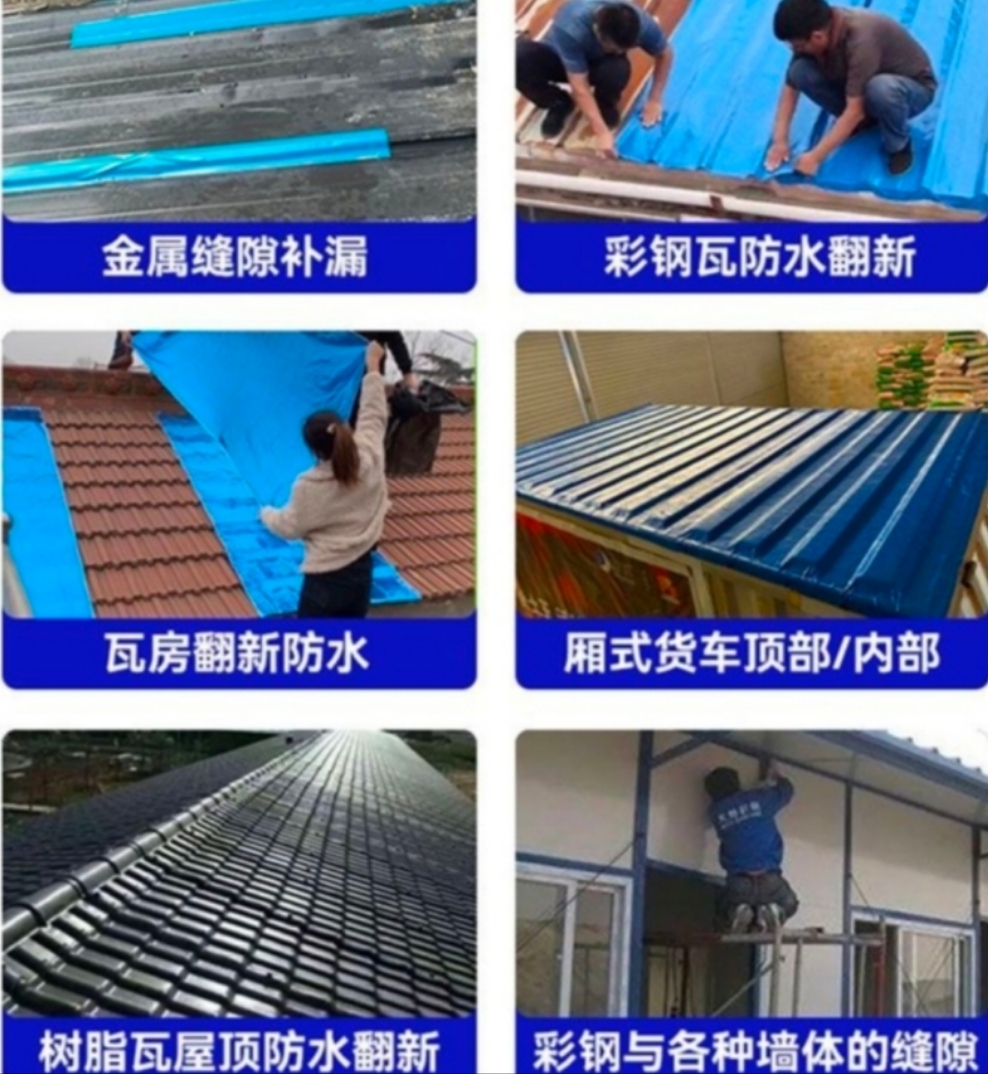

Application scope, suitable for electroplating, chemical, papermaking, ceramic, breeding, leather, dyeing and printing, high-temperature casting and other industries with severe corrosion, high waterproof and insulation requirements, such as color steel roof of factories, warehouses, and large shopping malls.

Please contact customer service for details, specifications, shipping, after-sales service, and wechat/phone number: 18639026652.

Construction base working conditions requirements:

1. The base surface of the color steel sheet is free from dust and loose parts. After the loose parts are treated, construction can be carried out.

2. The base surface must not have water, dust, or oil stains. If there are any, they must be treated before construction can begin.

3. If the gap between the color steel sheets exceeds 0.3mm, it needs to be reinforced. Only after treatment can construction proceed.

4. Corner angles, at the plane dark angles and vertical wall inner angles of the pile elevation, the gaps need to be processed.

5. Construction work must be stopped when there is dew on the color steel sheet roof in the morning.

6. When rusty color steel is used in construction, if the rusty surface exceeds 50%, rust removal is required on the color steel sheet. (Heat resistance up to 80°C, low temperature resistance down to -40°C)

7. When the cement base surface is connected, it is required that the cement base surface is firm and flat, and the base surface treatment agent is applied during construction.

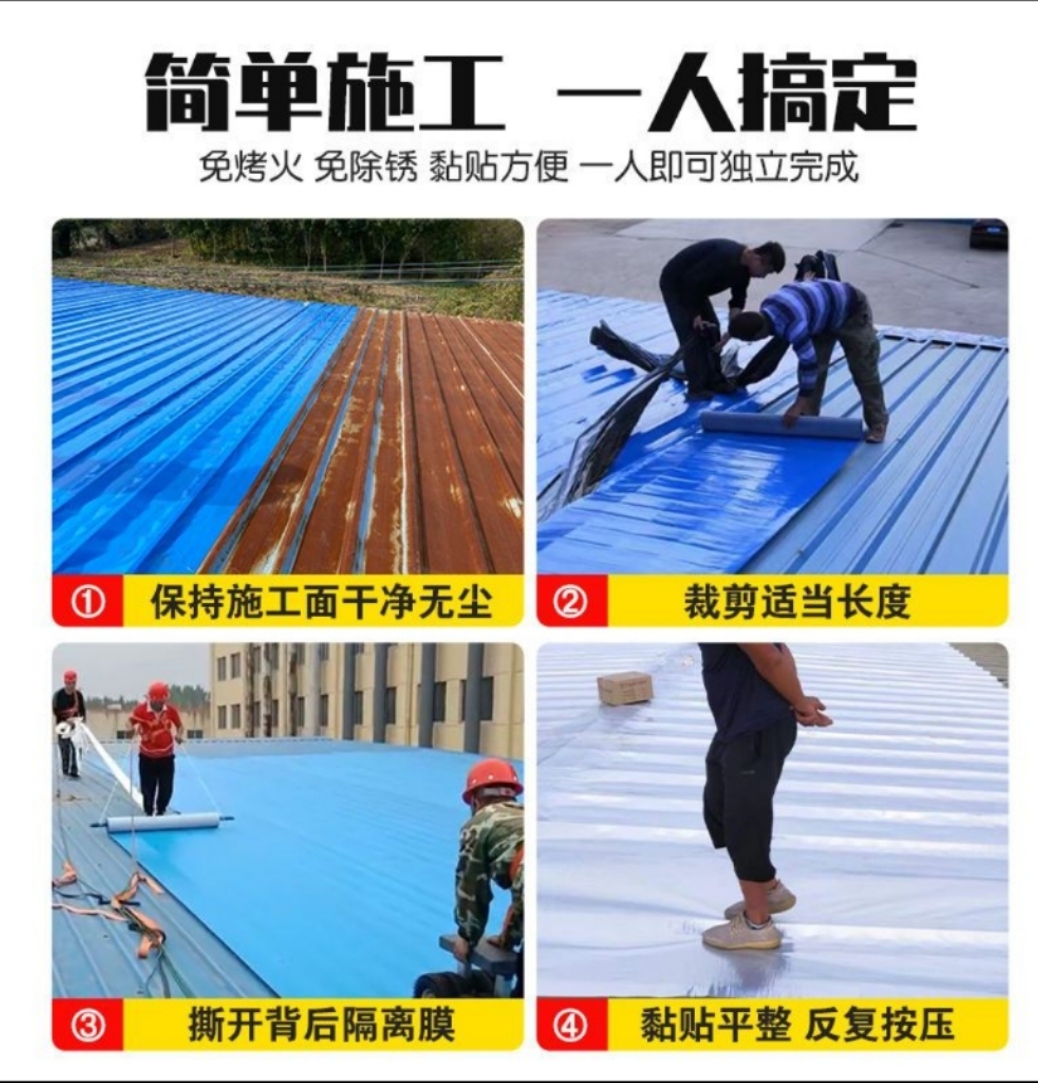

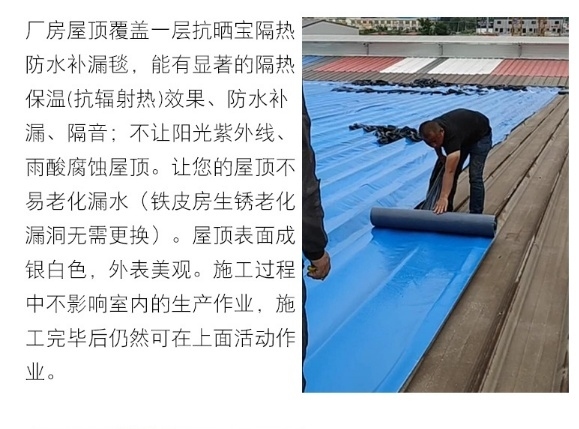

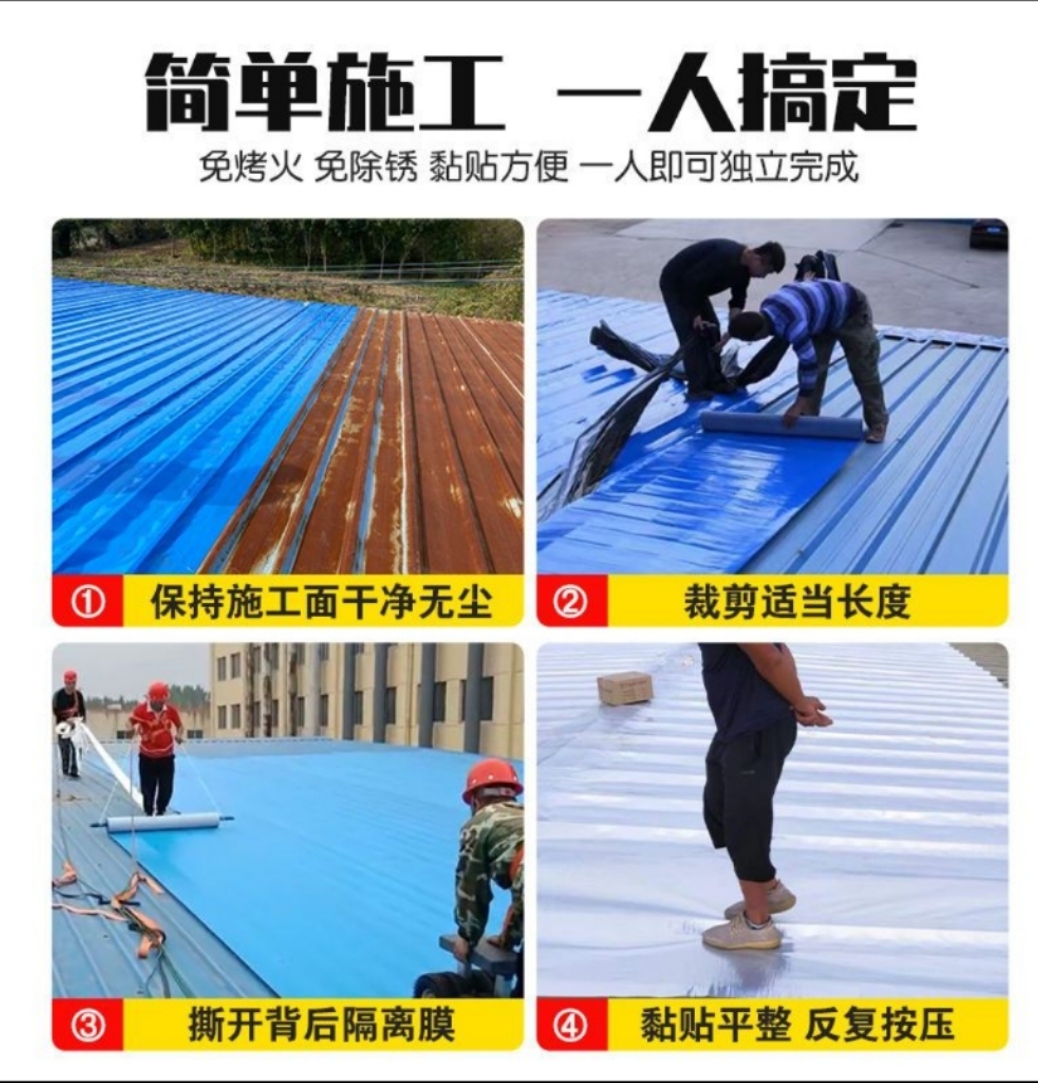

Construction Technology

1. Clean the base surface:

Wipe off the dust on the color steel roof with a mop. If there is any rust, it must be removed to achieve a smooth and clean surface.

2. Make an additional layer:

The additional layer should be applied at the corners, ventilation openings, and gutters, with a width of 15cm to 30cm. It should be extended along the central axis of the corners to be pasted.

3、Large-area construction:

A: First, draw a baseline to ensure that the rolled material is laid out neatly and beautifully.

B: When applying the membrane, align the sheet accurately at the intended construction site, starting from the water flow direction towards the downhill. For vertical surfaces, apply from the bottom towards the top.

C: Exclude air, roll the membrane to press out the air inside, and firmly adhere the membrane.

D: On the color steel sheet roof nails, the nail cap can be cut into small pieces and pasted with tape. For the maintenance of the old roof with local leakage, the local construction can be used for the pasting.

E:The overlap length of the membrane is 5cm.

F: When nailing the roofing felt, do not pull it too tightly. Loosen the felt to ensure that the nails do not exert excessive force on the felt.

4: Local Construction

For the local construction such as the overlap areas of color steel sheets, gutters, fans, and light wells,

Use self-adhesive tape to cover all the seams of the color steel tiles on the roof, the gutter, the fans, the light well, and other key areas.

The nail cap can be cut into small pieces and pasted with tape. For the repair of the old roof with local leakage, the local construction can be used for adhesion.

Notes;

1. The roof surface should be free of dust and thoroughly cleaned. For old roofs, you can wipe them down with a mop.

2. The best choice for the thickness of the membrane is 1.5mm or 2.0mm.

3. Construction should not be carried out on foggy days or immediately after heavy rain, as moisture can cause air bubbles.

4. The overlap between the roofing sheets and between the roofing sheets and the reinforcing layer must be firmly fixed and cannot have any flapping edges. If conditions allow, a water spray test can be conducted.

5. The newly constructed waterproof layer should not be randomly removed, as the material features a stronger adhesion over time. If it is removed more than twice, the adhesion will become unstable. It is necessary to apply a specialized base treatment before re-adhering.

6. Construction temperature shall not be lower than 5°C, and shall not exceed 35°C.

Please contact customer service for the detailed specifications of the construction, WeChat and phone number are 18639026652.

Construction base working conditions requirements:

Construction base working conditions requirements:

Notes;

Notes;