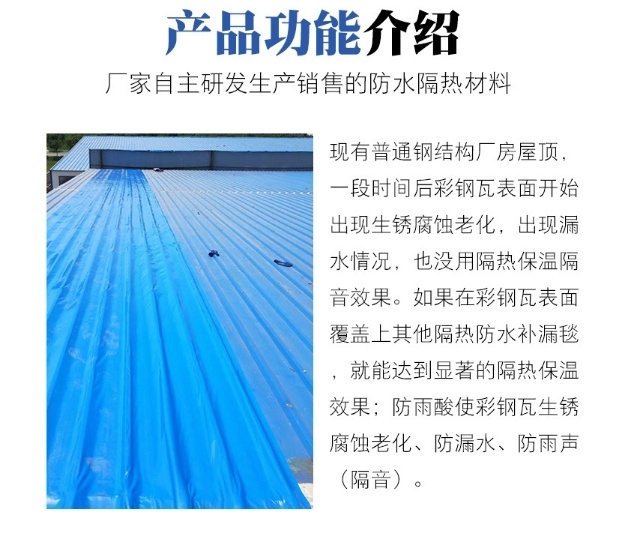

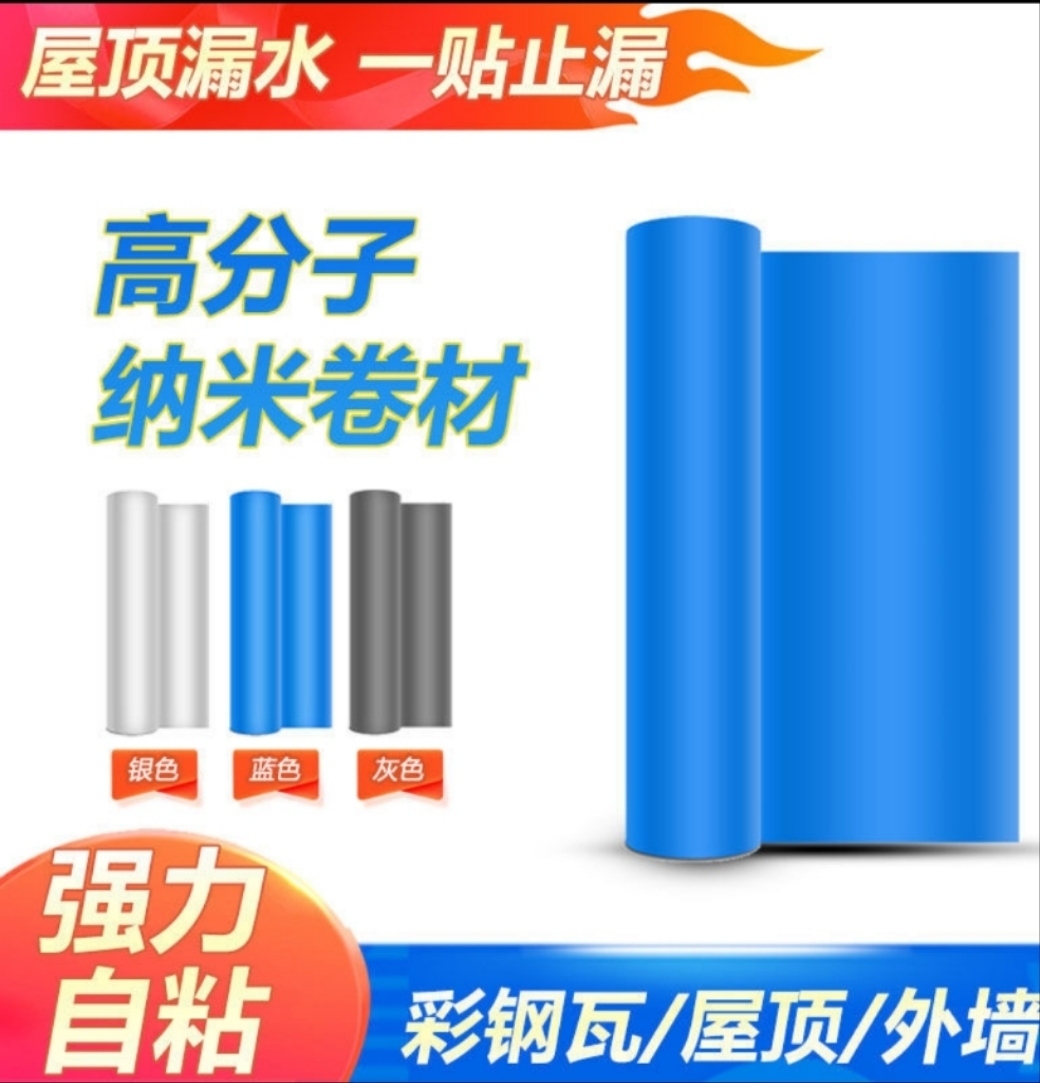

Henan Bangda Waterproof Material Co., Ltd. produces color steel tile roof steel structure waterproof membrane, cement roof self-adhesive waterproof membrane, factory roof waterproof membrane, building steel structure renovation anticorrosive waterproof membrane, width 1 meter, red, blue, gray, and silver.

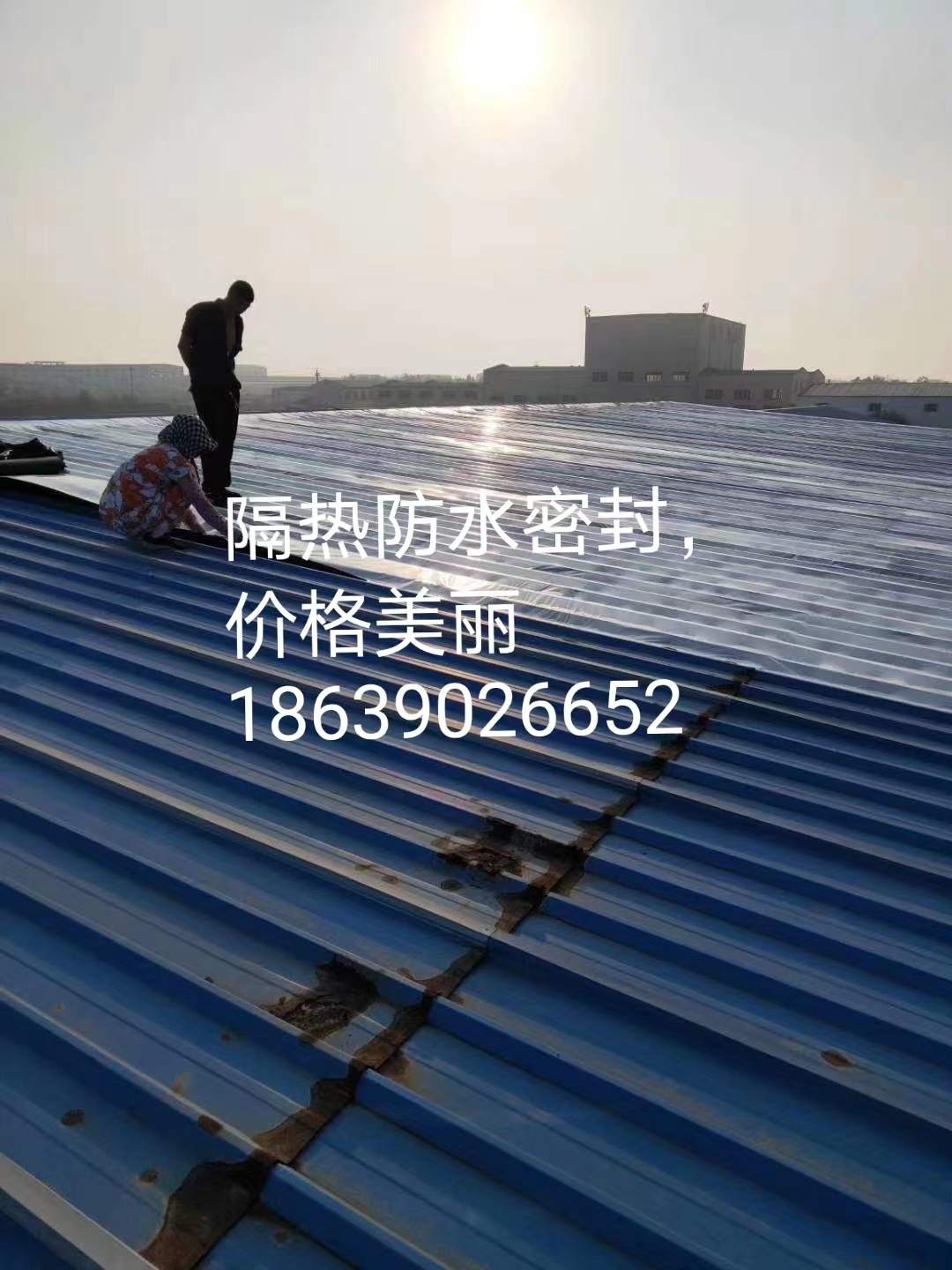

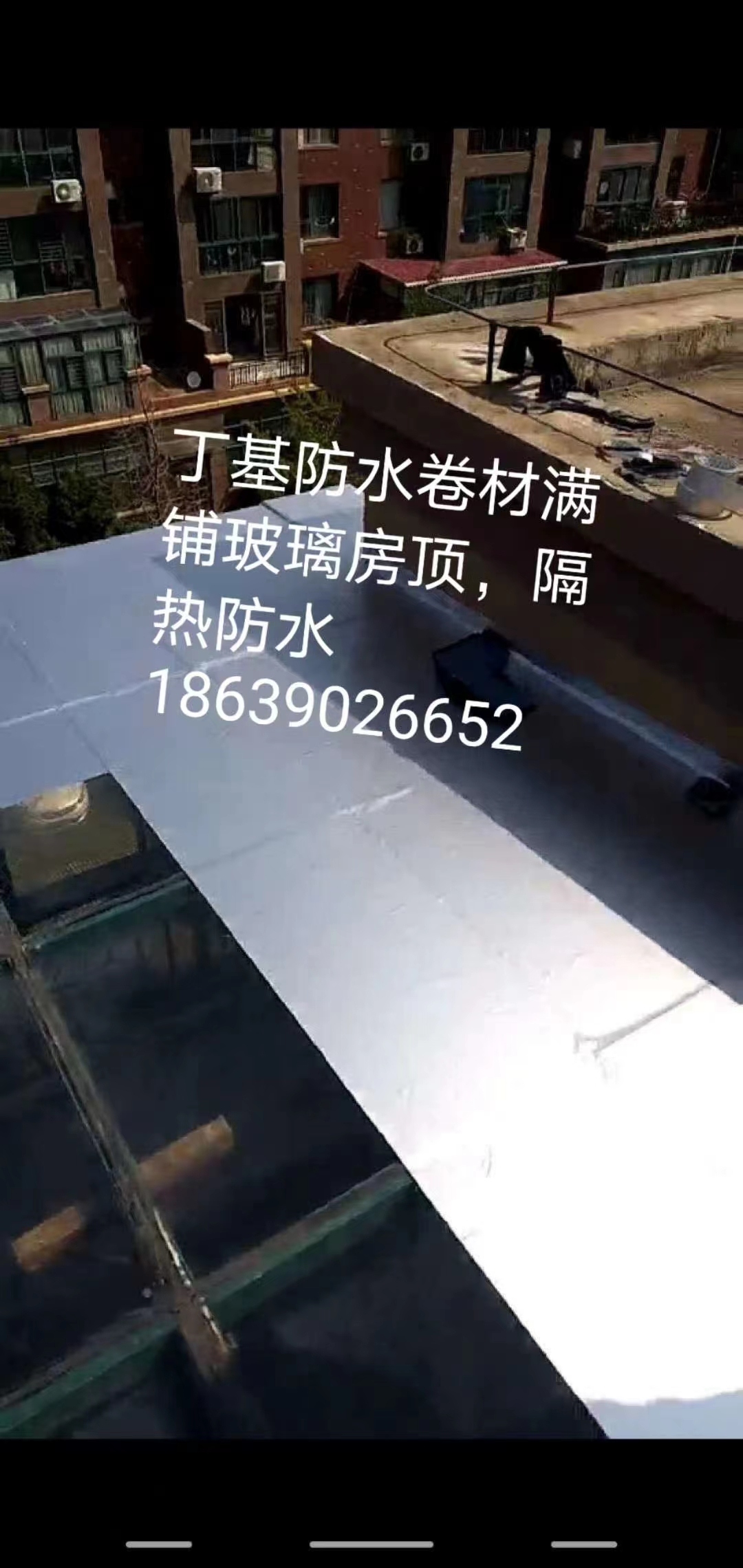

Color steel sheet self-adhesive waterproof and insulating membrane, dedicated self-adhesive waterproof membrane for full-coverage roofing, metal surface corrosion-resistant waterproof membrane, can last over ten years.

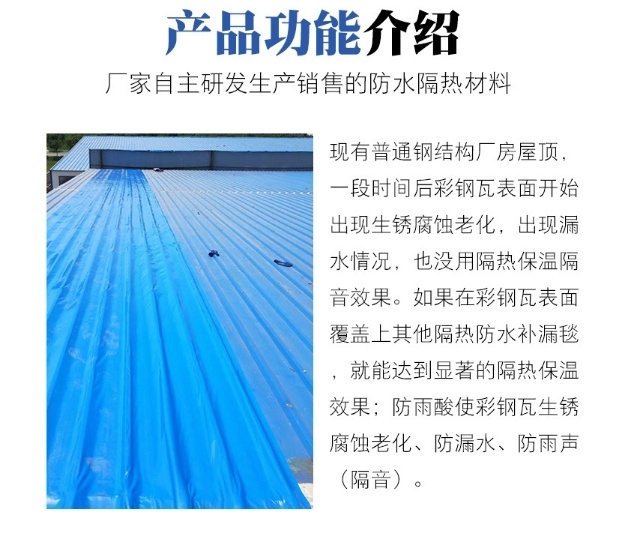

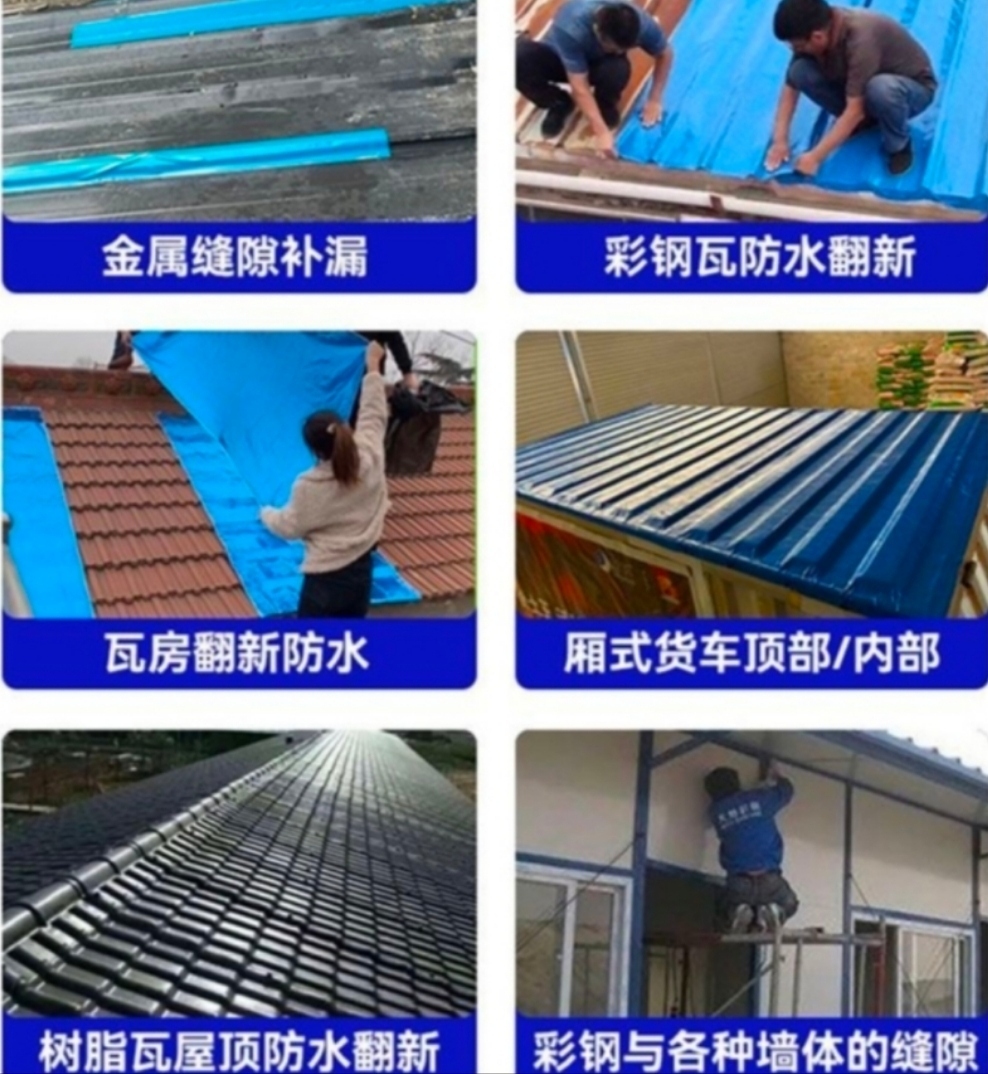

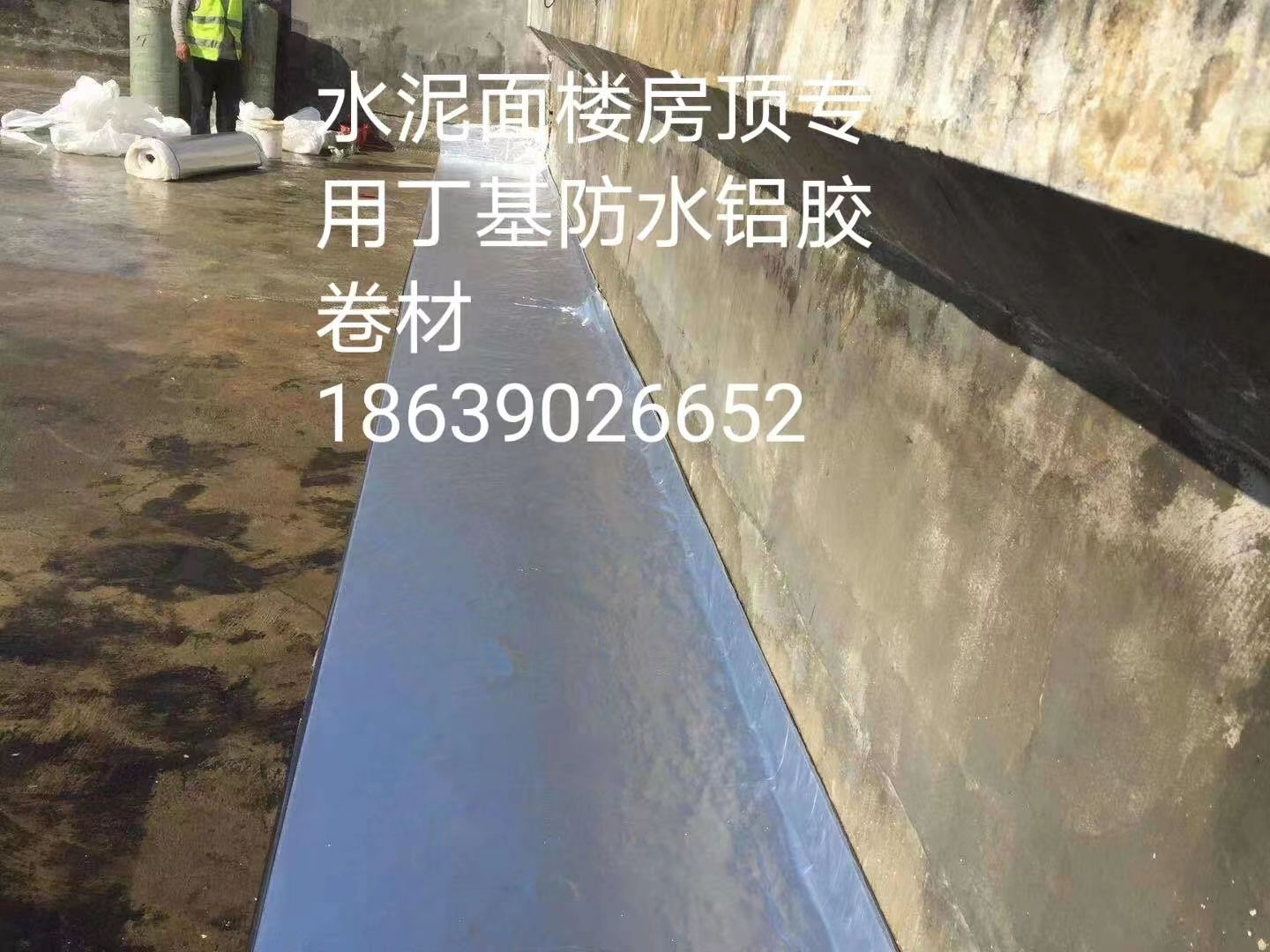

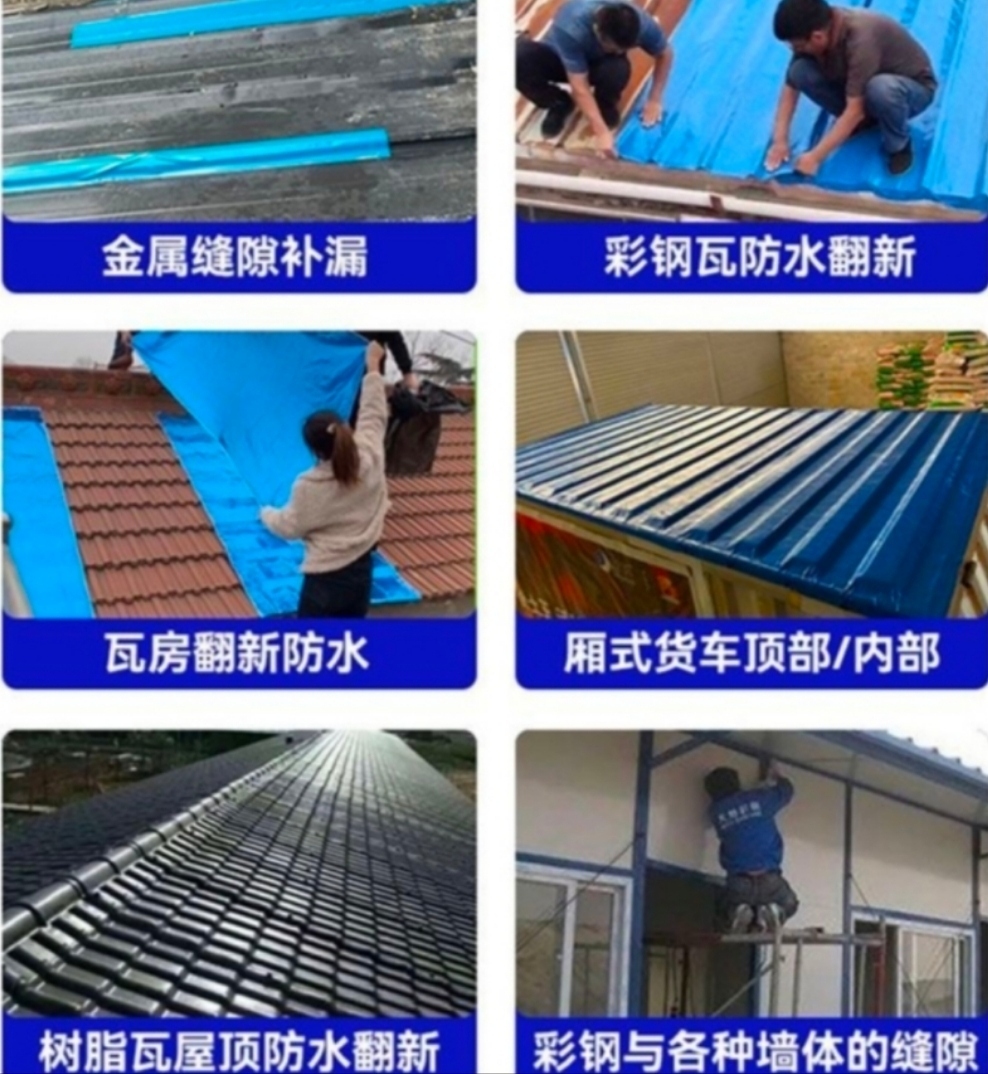

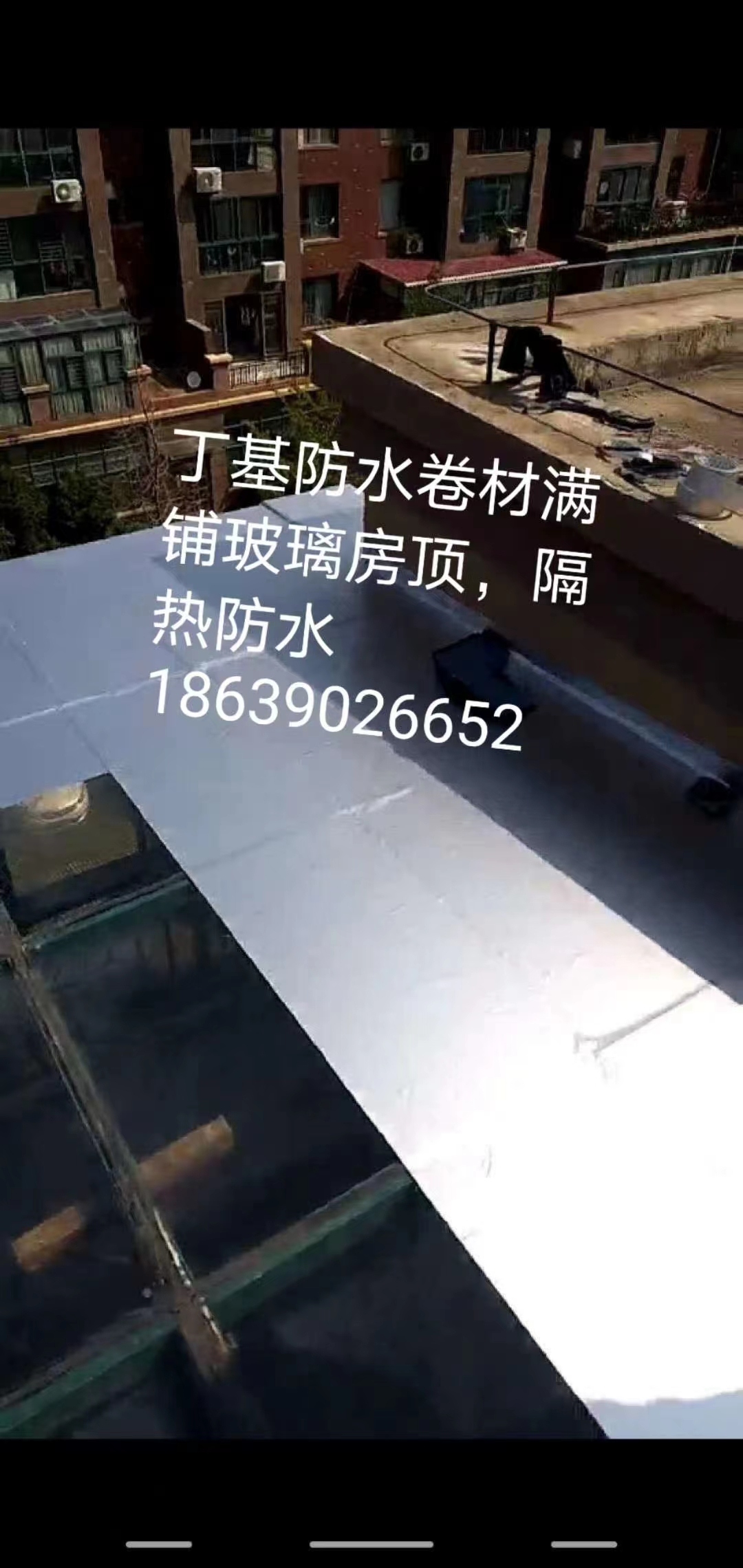

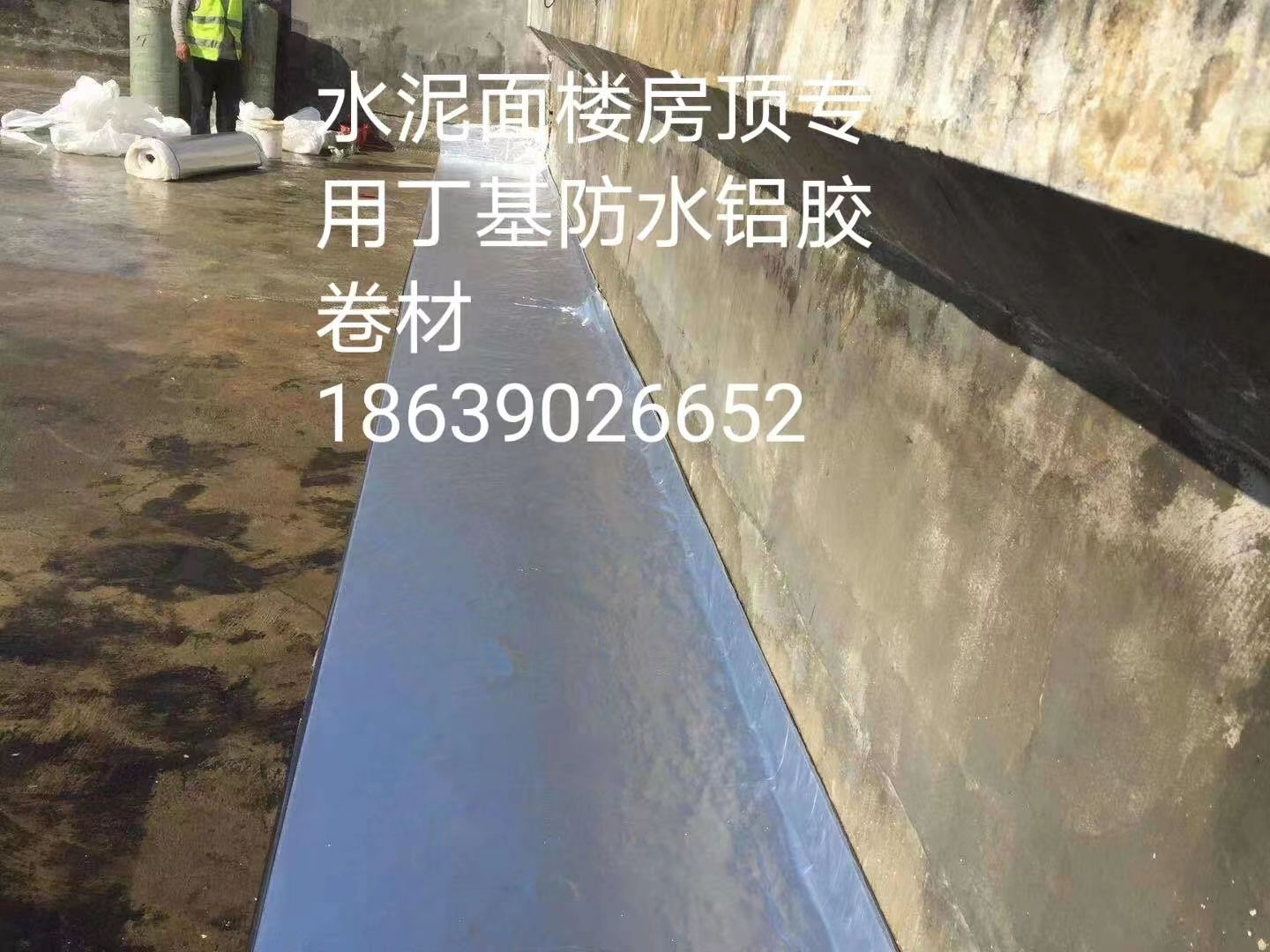

A roof covered with rusty and leaky color steel tiles, cement-painted building roofs, aging and leaky felt sheets, and glass-covered roofs for waterproofing and insulation, with simple construction, no need for fire-baking or glue application, simply paste directly, and can last over ten years.

Application scope, suitable for electroplating, chemical, papermaking, ceramic, breeding, leather, dyeing and printing, high-temperature casting and other industries with severe corrosion, high waterproof and insulation requirements, such as color steel roof of factories, warehouses, and large shopping malls.

Please contact the customer service at 18639026652 for details of the specifications and colors.

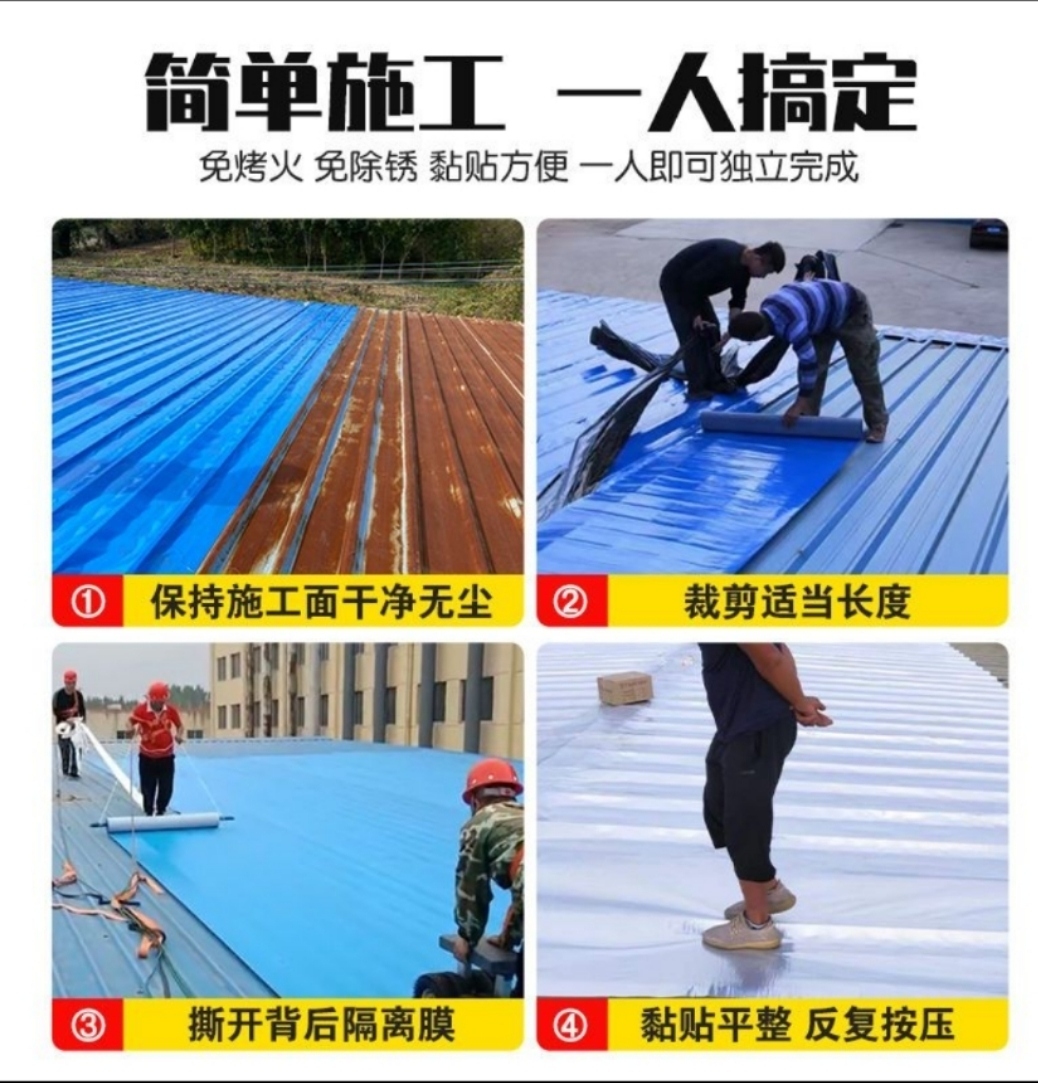

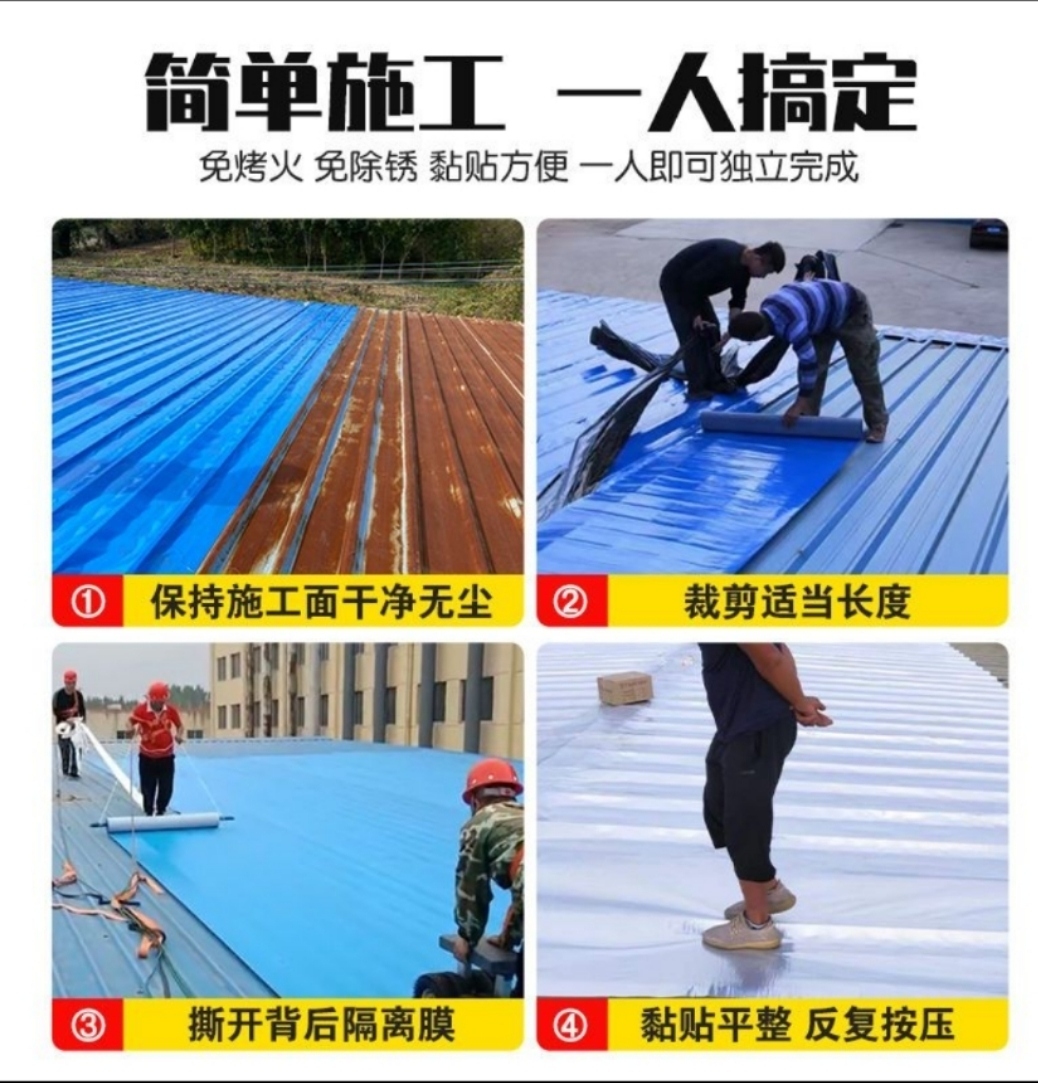

Color steel roof construction technology

Color steel sheet self-adhesive waterproof membrane, as a building material, is widely used in industrial plant construction and civilian roof construction due to its light weight, environmental protection, and high cost performance. It is effective in preventing leaks, rust, and rain seepage on color steel sheet roofs.

Waterproofing base condition

1. Ensure that the base surface of the corrugated steel sheet is free from dust and is not loose. If there are loose conditions, they need to be treated before construction can begin.

2. The base surface cannot have water accumulation, and if there is water accumulation, it must be reinforced and treated until it is qualified before the construction of the waterproof layer can begin.

3. When necessary, the gaps in color steel tiles should be reinforced, and then construction can proceed.

4. Additional layers are required for corners of the Yin-Yang angle, the vertical plane, and the plane of the Yin angle, as well as the interior and exterior angles of the elevation.

5. Construction work is to be stopped if dew is found on the color steel sheet roof in the morning.

6. When construction is carried out in severe winter, a primer is needed to be applied to the corrugated steel sheet.

Section Two: Operating Process

1. Clean the base surface: Check the dirt and rust on the base surface, wipe away the dust with a cloth, and if there is any iron rust, it also needs to be removed. Rinse the roof with water to clean it and keep it flat.

2. Make an additional layer: Additional layers are needed at places such as corners with different directions, ventilation openings, and gutters, about 15cm to 30cm in thickness, and they should be extended along the central axis of the corners with different directions.

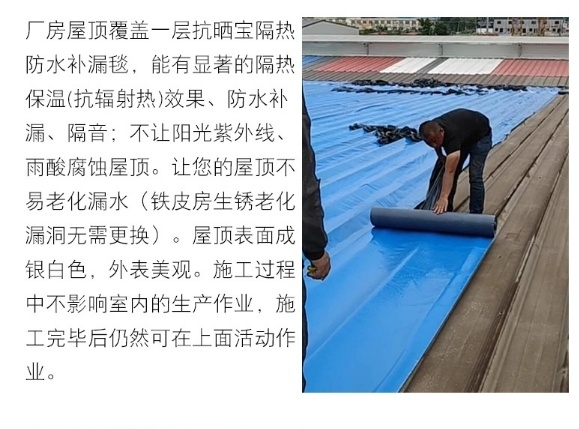

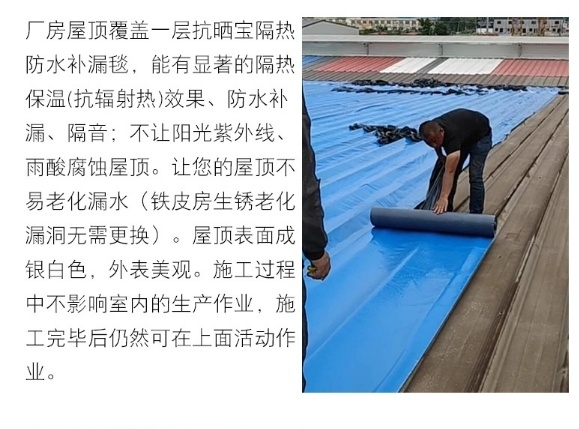

3. Construction: First use the baseline, and the rolled material laid out will achieve a neat and beautiful effect; align and position the rolled material with the construction area, and you can roll up the material from both sides; cut the isolation paper from the middle, and as you peel off the isolation paper, squeeze the rolled material to maintain its flatness.

4. Requirements: When laying the membrane, start from the direction of the water flow, and start from the top down on the vertical wall. To eliminate air, roll the membrane to squeeze the air inside, thereby achieving a firm adhesion effect of the membrane; when the temperature is low, both the membrane and the base layer need to be coated with a base treatment agent; the length of the membrane overlap on the long side is 3cm~8cm, and the short side is 10 cm; the exposed short side overlap of the membrane and the membrane ends need to be sealed with sealant.

Color steel roof construction technology

Section Three: Tiling Methods

The method of covering: apply waterproof membrane specially designed for color steel roofing on the entire surface of the color steel roofing, which can ensure the roof is fully waterproof and corrosion-resistant.

Section 4: Construction Precautions

1. The roof should not have any dust. If a coating agent is needed, it should not be too thick.

2. The thickness should be selected between 1.5mm and 2mm.

3. Construct only when conditions are suitable. Do not begin work on foggy days or immediately after heavy rain, as moisture can cause air bubbles.

4. The overlap of the long and short edges of the membrane should be at least 10cm.

The overlap between the roofing sheets and between the roofing sheets and the reinforcing layer must be firmly fixed.

6. For newly constructed waterproof layers, they should not be casually removed, as the longer the bonding time, the more firmly the material adheres. If the layer is removed more than twice, it is easy to experience poor bonding. It is essential to apply a primer to ensure complete bonding.

7. When the temperature of the roof is too high, it is not recommended to store a large amount of materials on the roof. It is better to use one roll and place it, to avoid making it difficult to peel off the isolation film of the roofing material.

Product Features:

1. Sunscreen, heat insulation, and light reflection: The surface temperature can be reduced by more than 20 degrees when exposed to the sun in summer, and the indoor temperature of the factory can be reduced by 6-12 degrees.

2. Waterproofing, rustproofing, acid-proof, corrosion resistance, UV resistance

3. Prevent roof aging, extend the service life of color steel roof factory more than 10 years, with beautiful appearance, and it is still possible to move around on the roof after construction is completed.

4. Effective rain noise isolation, particularly significant for steel structure factory roofs.

5. Corroded and leaky steel roofing does not need to be replaced.

6. Resistant to cold, unaffected by -40°C, with an outer aluminum layer for fire resistance and flame retardancy.

● Application Scope:

Usually suitable for the roof of steel structure factory buildings and other building top floors, insulating, waterproofing, sound insulation, anti-rust, damage repair, aging renovation: It is one of the more high-quality insulating and waterproofing materials. After installation, when exposed to the summer sun, it can reduce indoor temperature by 30%-40%, and the higher the temperature, the greater the cooling effect.

Add WeChat 18639026652 when needed.

Color steel roof construction technology

Color steel roof construction technology

Product Features:

Product Features: