Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

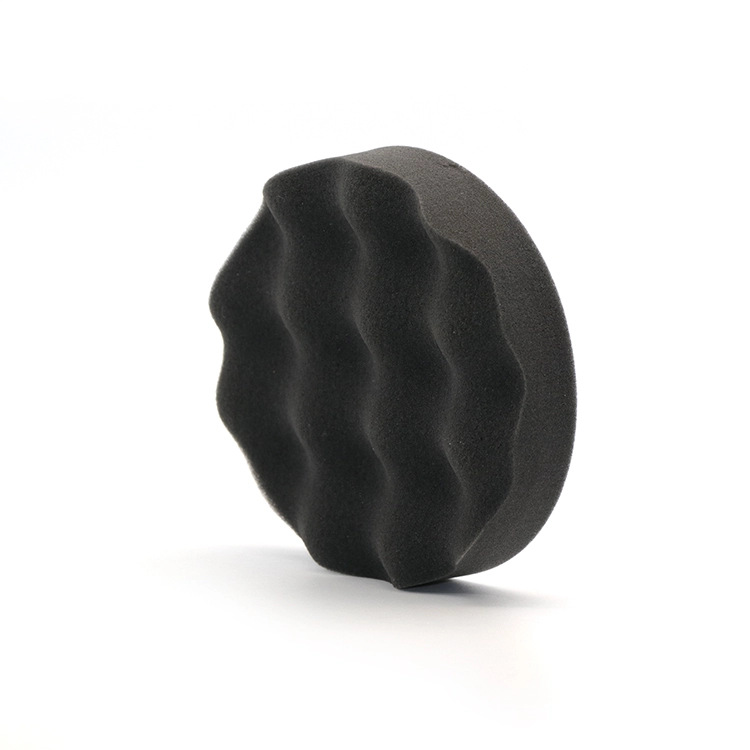

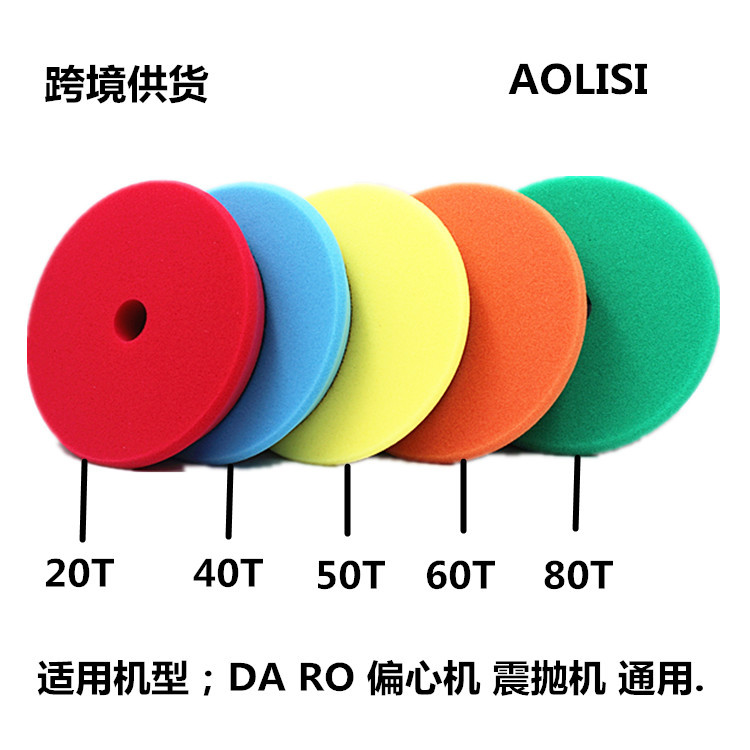

【 product features]: good toughness and strong wear resistance

[Instructions]]:

1: suitable for waxing, polishing, sealing glaze

2: pneumatic or electric polishing machine can be used

3: When waxing the product, it is recommended to use 1000-1500 r/min

4: When polishing the product, it is recommended to use 1500-2000 r/min

in order to ensure the polishing effect, the vehicle must be thoroughly cleaned before waxing.

● waxing: waxing can be divided into manual waxing and mechanical waxing. Manual waxing is simple and easy to operate, and mechanical waxing efficiency is high. Whether it is manual or mechanical waxing, make sure that the paint surface is evenly applied. When manual waxing, first apply a proper amount of car wax on the sponge (special waxing sponge), and then apply it in a straight line in a certain order, each smear should have a coincidence degree of 1/5-1/4 with the upper smear area to prevent leakage and ensure uniform smear. When mechanical waxing, apply the car wax on the sponge of the waxing machine. The specific coating process is the same as that of manual work. It is worth noting that the coating on the edges, corners and edges should avoid exceeding the paint surface, in this respect, manual smearing is easier to grasp.

● polishing: according to the instructions of different car wax, it can be polished in 5-10 minutes after applying. When polishing, follow the principle of waxing first and polishing first to ensure that the polished car table is not polluted. The polishing work usually uses non-woven wool reciprocating rectilinear movement, and press it properly to remove the remaining car wax.

Pay attention to the following problems when polishing and waxing:

1. The waxing operation environment is clean and well ventilated.

2. The car should be waxed in the shade, otherwise the temperature of the car table will be high, and the adhesion ability of the car wax will decrease, which will affect the waxing effect.

3. When waxing, the running route of manual sponge and waxing machine sponge should be straight reciprocating, and it is not suitable for annular smear to prevent strong annular diffusion caused by uneven coating.

4. Waxing should follow the principle of first up and then down, that is, first smear the roof, front and rear cover, side of the car body, etc.

5. When waxing, if the sponge has the same color as the car paint, it may be that the paint surface has been damaged, stop waxing immediately and repair it.

6. The polishing operation should be carried out within the specified time after the completion of waxing, and the polishing movement is also straight reciprocating. Unpolished vehicles are never allowed to drive on the road. Otherwise, polishing will easily cause scratches on the paint surface.

7. After polishing, carefully check and remove the remaining wax from the license plate, car lamp, door edge, etc. to prevent corrosion.

8. After waxing, the equipment and supplies should be properly cleaned and stored.

9. To master the frequency of waxing, due to the different driving and parking environments of the car, the waxing interval cannot be carried out step by step, but the paint surface of the car body can be wiped by hand. If there is no sense of smoothness, waxing should be carried out again.

Update time:

TOP