Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| hg-120/220v | CN¥ 410.0 | 997 set available |

|

| hg-180/220v | CN¥ 440.0 | 100 set available |

|

| hg-200/220v | CN¥ 510.0 | 997 set available |

|

| hg-250/220v | CN¥ 539.0 | 100 set available |

|

| hg-370/220v | CN¥ 650.0 | 100 set available |

|

| hg-370/380v | CN¥ 650.0 | 100 set available |

|

| hg-750/220v | CN¥ 750.0 | 997 set available |

|

| hg-750/380v | CN¥ 730.0 | 100 set available |

|

| hg-1100/220v | CN¥ 1100.0 | 100 set available |

|

| hg-1100/380v | CN¥ 1150.0 | 100 set available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Jitai e-commerce Co., Ltd 5yr.

Contacts:Hu Qingxiu Chat

Mobile:86-13264805277

E-mail:573693426@qq.com

one.Working Principle and Features:

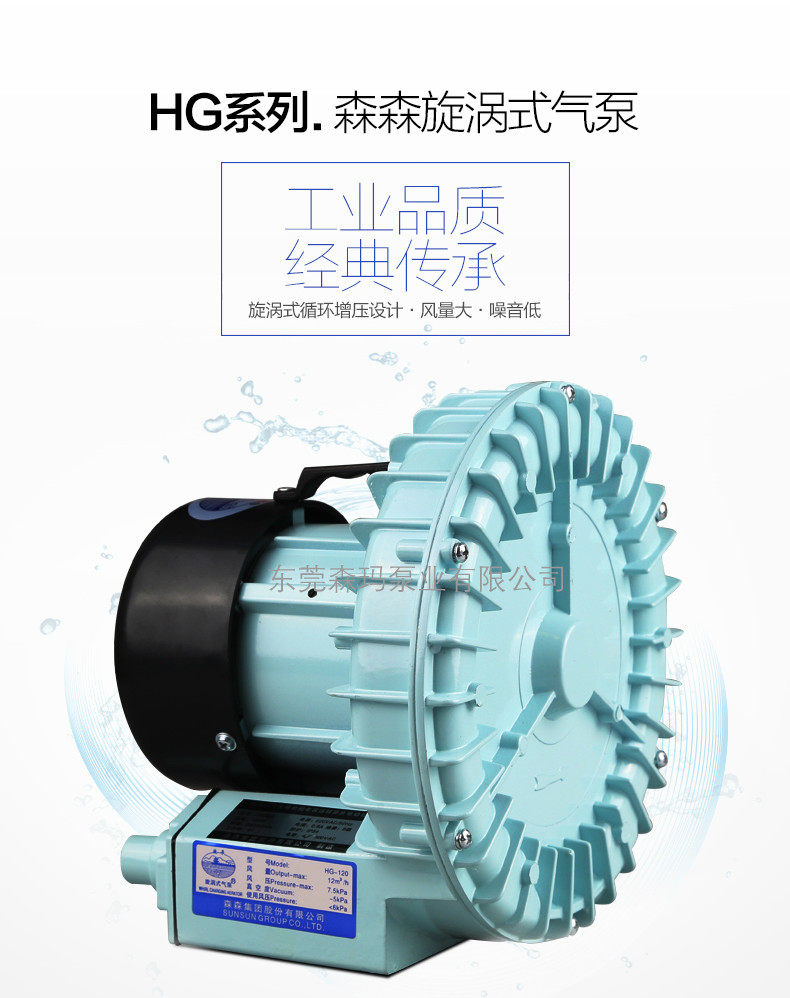

The impeller of the PG series high-pressure vortex air pump is composed of dozens of blades, which is similar to the impeller of a large gas turbine. The air in the middle of the impeller blades is subjected to centrifugal force, moving towards the edge of the impeller, where the air enters the circular cavity of the pump body and then re-circulates in the same way from the start of the blades. The circulation airflow generated by the rotation of the impeller leaves the air pump with high energy for use. The air pump uses a special explosion-proof motor, which has a compact structure, small volume, light weight, low noise, and delivers air without water or oil.

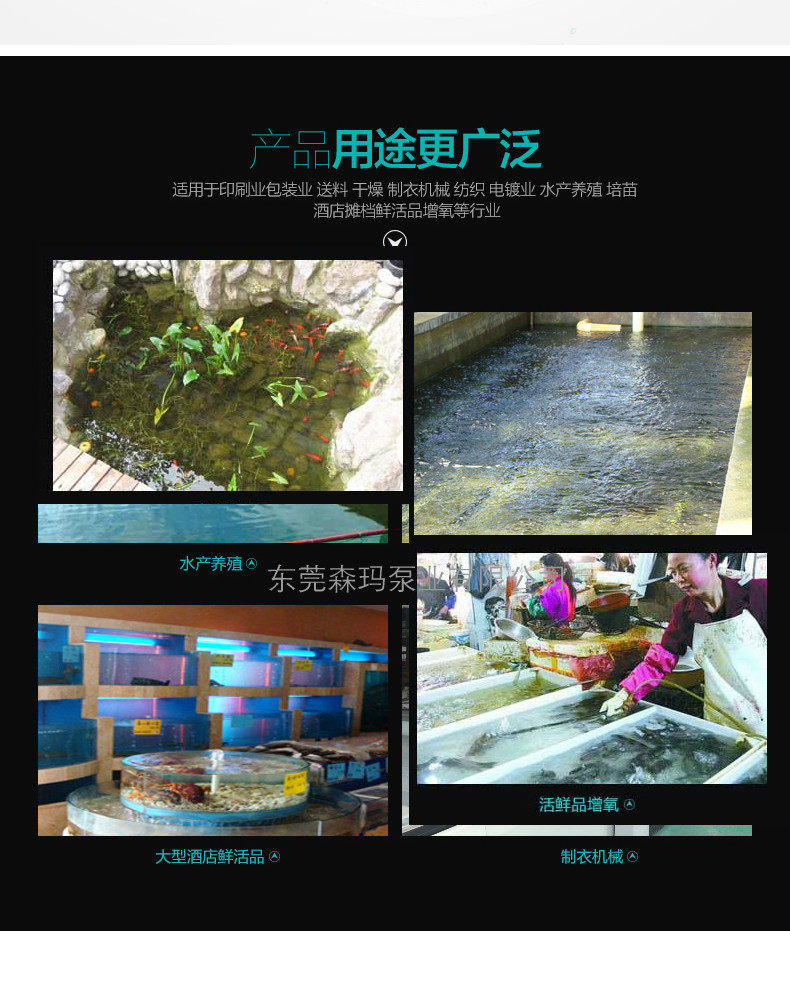

Section Two: Uses and Application Scope:

The HG series vortex air pump is a dual-purpose ventilation source that can be used for blowing and ventilation. It is mainly used in: paper cutting machines, combustion deoxygenation machines, winding machines, filter tip forming machines, electroplating trough liquid stirring, atomization drying machines, aquaculture oxygenation, water treatment aeration, screen printing machines, photographic plate making machines, automatic feeding machines, liquid filling machines, powder filling machines, welding equipment, film machinery, paper conveying, dry cleaning of clothes, air dust removal, drying bottles, gas transmission, feeding, and collection.

Section Three: Use and Maintenance:

1. High-pressure vortex air pumps should be placed on a stable surface, and the surrounding environment should be clean, dry, and well ventilated.

2, the rotation direction of the high-pressure vortex air pump impeller must be consistent with the arrow direction indicated on the fan cover.

3, when the high-pressure vortex air pump is working, the working pressure shall not exceed 8kpa to prevent the air pump from generating excessive heat and the motor from exceeding the current, which may cause damage to the air pump.

4, The high-pressure vortex pump has no direct contact friction with other parts except for the two bearings of the motor rotor. The bearing installation of this pump is mainly divided into two categories. The bearing at the pump end is installed in the pump body between the motor base and the impeller. This type of pump does not need to add lubricating grease normally. The bearing at the pump end of the second category is installed in the middle of the pump cover. The bearing at the pump end of this category should be regularly added with lubricating grease (7018 high-speed lubricating grease). For the pumps that work continuously for three shifts, the oiling frequency should be increased. The maintenance and maintenance of the bearing at the fan end of the motor for this type of pump should follow the same procedure as the first category of pumps.

5, the filter mesh and noise reduction device at both ends of the high-pressure vortex air pump should be cleaned in time according to the situation to avoid blockage and affect the use.

6, The inlet and outlet of the high-pressure vortex air pump must be connected with soft tubes (such as rubber tubes, plastic spring tubes).

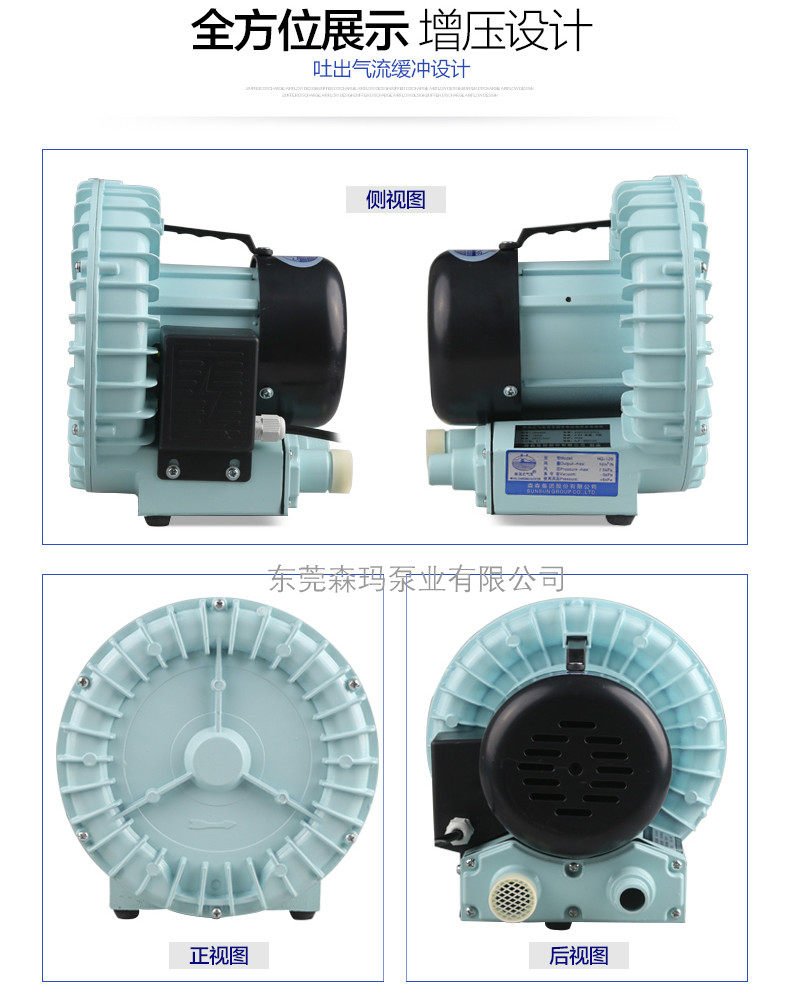

7. Replacement of Bearing in High-Pressure Turbine Air Pump: The replacement of the bearing must be performed by someone familiar with repair work. First, loosen the screws on the pump cover, then disassemble the parts in the sequence shown in the diagram. The disassembled parts should be cleaned, and then assembled in reverse order. When disassembling, do not forcefully pry the impeller; it should be pulled out with a special puller. At the same time, do not overlook the adjustment washers, as they may affect the pre-set gap that has been adjusted by the manufacturer.

8, High-pressure vortex pumps are strictly prohibited from solid, liquid, and corrosive gases entering the pump body.

Model and Parameters

Update time:

TOP