Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| 0.15mm thick | CN¥ 2.53 |

| 0.20mm thick | CN¥ 3.91 |

| 0.25mm thick | CN¥ 4.51 |

| 0.3mm | CN¥ 5.5 |

| 0.35mm | CN¥ 6.51 |

Miaotian adhesive tape factory 5yr.

Contacts:jianchen Chat

Mobile:86-15988599892

E-mail:1376878055@qq.com

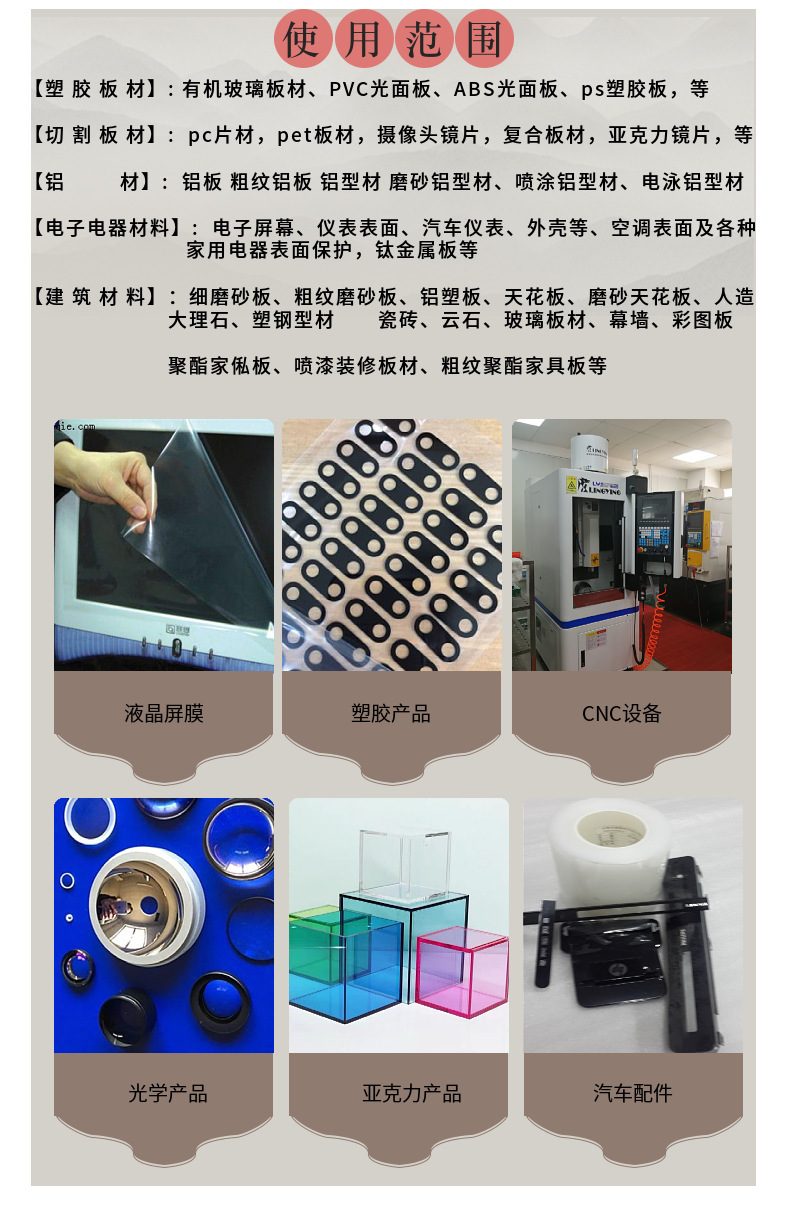

CNC cutting of PE protective film is a common manufacturing process for electronic products. The following introduces the production process and how to select the appropriate viscosity and thickness combination.

1. Production Process

(1)Selection of Film Materials: PE Protection Films are typically made from polyethylene (PE) due to its excellent toughness and wear resistance, along with being easy to process and mold during the manufacturing process.

Processing of Film Materials: The production of PE protective films generally employs a CNC cutting process, which involves first designing the pattern and dimensions of the film on a computer, and then placing the film on a cutting machine for cutting. The automated cutting machine ensures the accuracy of the film material and is capable of completing efficient production tasks.

(3) Surface treatment of the membrane: In the production process, the surface of the membrane needs to be processed. Common treatment methods include coating, spraying, etc. These methods can protect the membrane surface from water, dust, and scratching, and also improve the luster of the membrane surface.

2. How to choose the viscosity and thickness combination

Normally, we choose a thickness of 0.15mm for our ordinary products. If there are higher requirements, we also have options for 0.2mm, 0.25mm, 0.3mm, and 0.35mm. The selection of adhesive viscosity and thickness needs to consider the use environment and wear degree. When selecting adhesive viscosity, it is necessary to choose the appropriate viscosity according to the surface to be protected. Generally, smooth surfaces use low-viscosity films, while rough surfaces choose high-viscosity films. In terms of thickness selection, it is necessary to consider the product's wear resistance and use environment. Generally, for products with large mechanical wear, thicker films are needed, while for ordinary application scenarios, thinner protective films can be chosen. It should be noted that at the same time, it is also necessary to select the appropriate size and color according to the specific application scenario to meet the needs of different users.

I hope these information can be helpful to you.

013

Update time:

TOP